Array multi-nozzle electrospinning device

An electrospinning, multi-nozzle technology, which is applied in the production of complete sets of equipment for man-made threads, textiles and papermaking, filament/thread forming, etc. , to achieve good application prospects, easy disassembly and installation, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

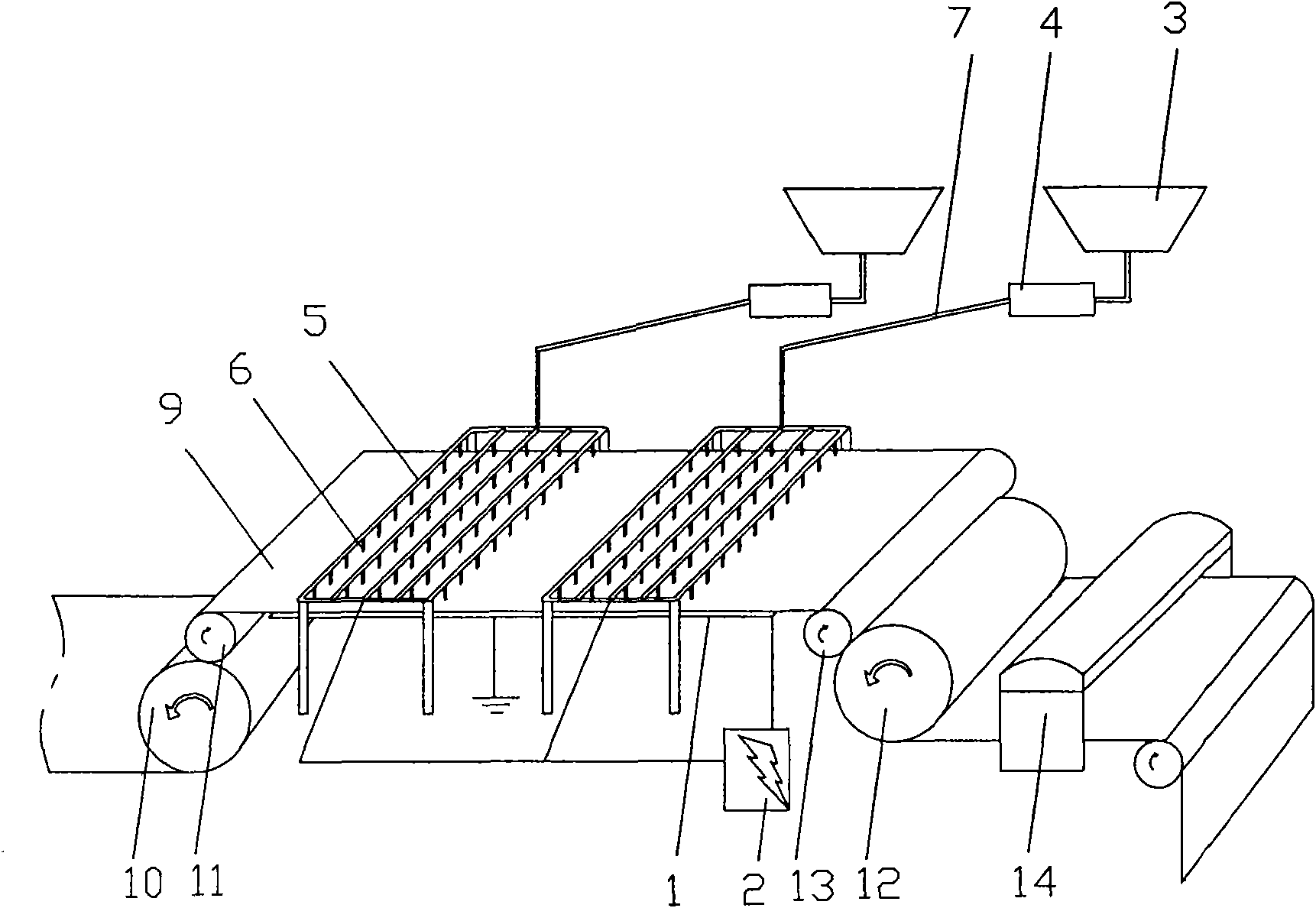

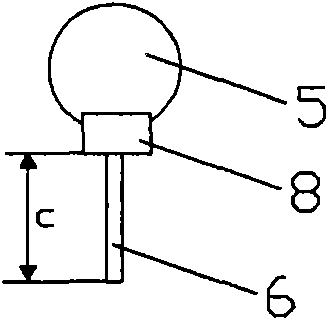

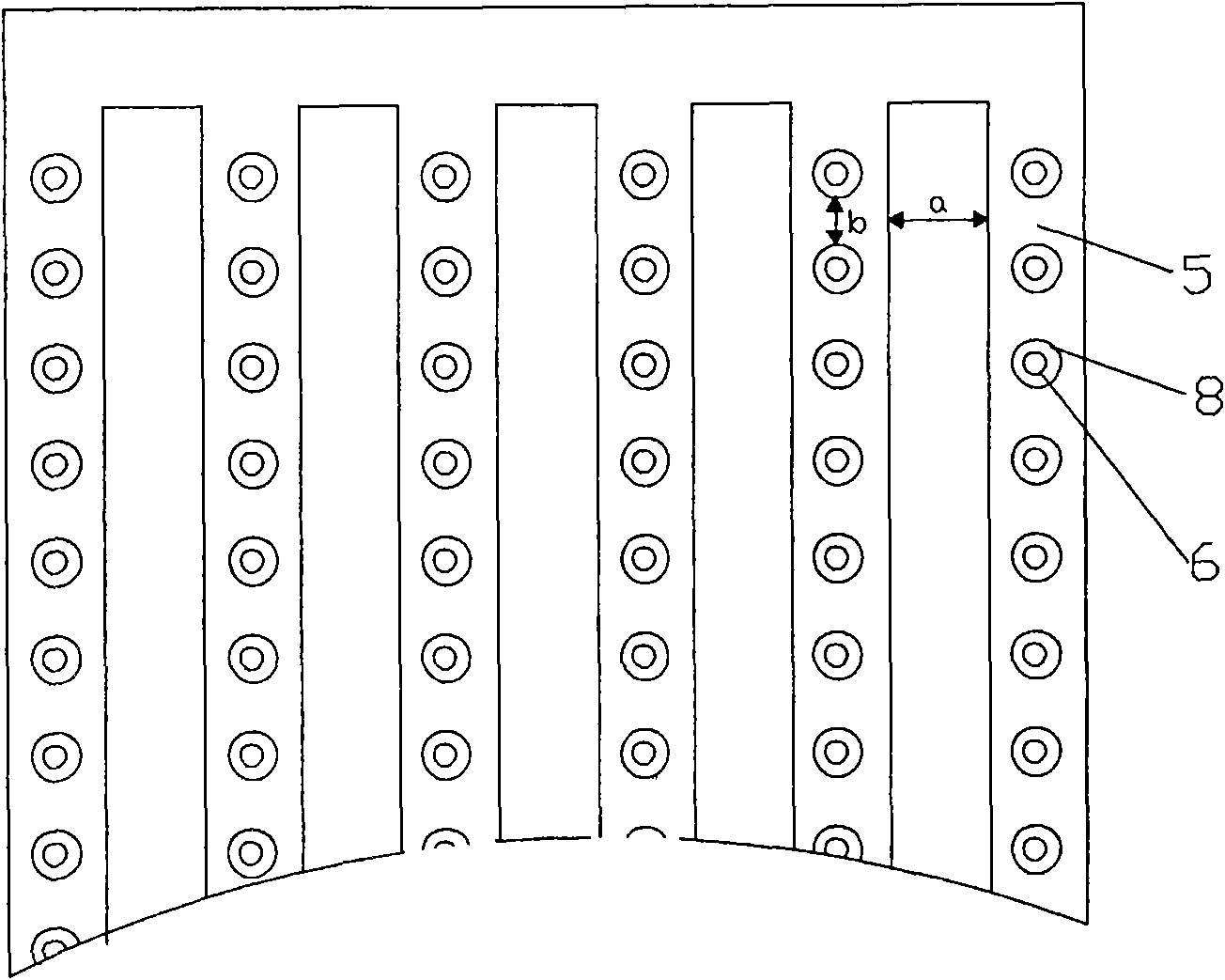

[0022] figure 1 It is a structural schematic diagram of an array multi-nozzle electrospinning equipment of the present invention; figure 2 It is a schematic diagram of the connection structure of the nozzle and the nozzle; image 3 It is a schematic diagram of the horizontal bottom surface of the electrospinning liquid spinning device; as Figure 1~3 Shown:

[0023] The array multi-nozzle electrospinning equipment of this embodiment includes an electrospinning solution supply device, an electrospinning solution spinning device, a receiving electrode plate 1, a high-voltage electrostatic generator 2, an electrospinning fiber delivery device, and an electrospinning fiber post-processing device 14;

[0024] The electrospinning liquid supply device includes a liquid reservoir 3 and an infusion pump 4;

[0025] The electrospinning liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com