Method for preparing micro-nano-scale patterned electrospun fiber membrane

An electrospun fiber, micro-nano technology, applied in fiber processing, textiles and papermaking, and clustering of newly extruded filaments, etc., can solve the problems of inability to produce patterned electrospun fiber membranes, and achieve a high degree of automation and processing Convenient and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] A specific embodiment of the present invention is a method for preparing a micro-nano-scale patterned electrospun fiber membrane, the steps of which are:

[0022] A. Use a computer to draw the required pattern through the layout design software;

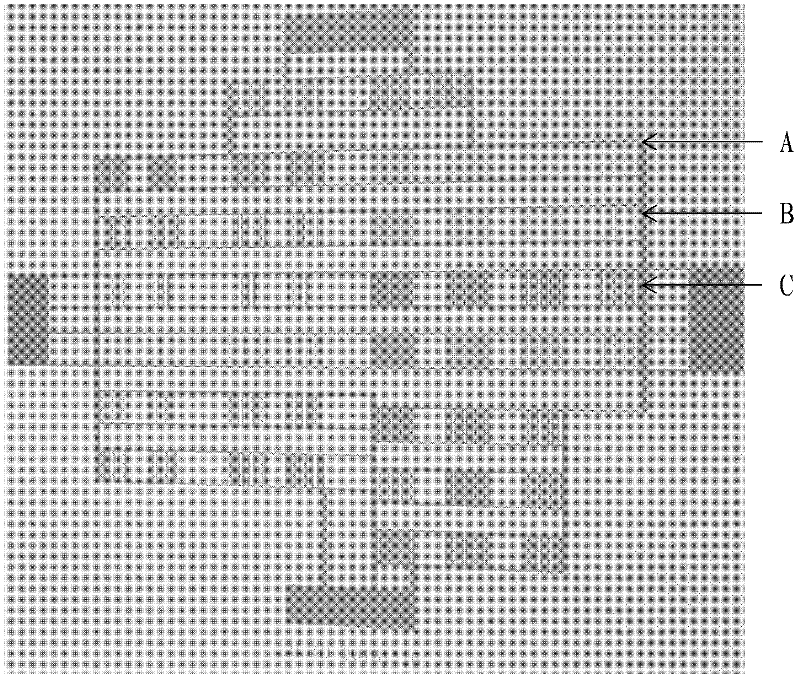

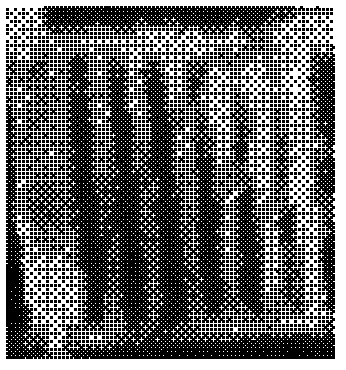

[0023] B. Input the pattern into the micro-electromechanical system, and the micro-electromechanical system deposits the metal on the non-metallic substrate according to the input pattern to obtain a receiving plate with micro-nano-level patterns;

[0024] In step B of this example, the metal is deposited on the non-metallic substrate by the MEMS according to the input pattern, and the specific method of obtaining the receiving plate with the micro-nano-scale pattern is: first, the photolithography of the MEMS The machine engraves the pattern on the non-metallic substrate, and then uses the DC magnetron sputtering machine of the MEMS to deposit the metal on the engraved points of the non-metallic substrate.

[0025] C. Using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com