Ultrafine continuous fibrous ceramic filter and method of manufacturing same

a technology of fibrous ceramic filter and ultrafine, which is applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of reducing process flow rate, degrading flow rate, and drastic pressure drop, and achieves low pressure drop upon filtration , high permeation flow rate, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

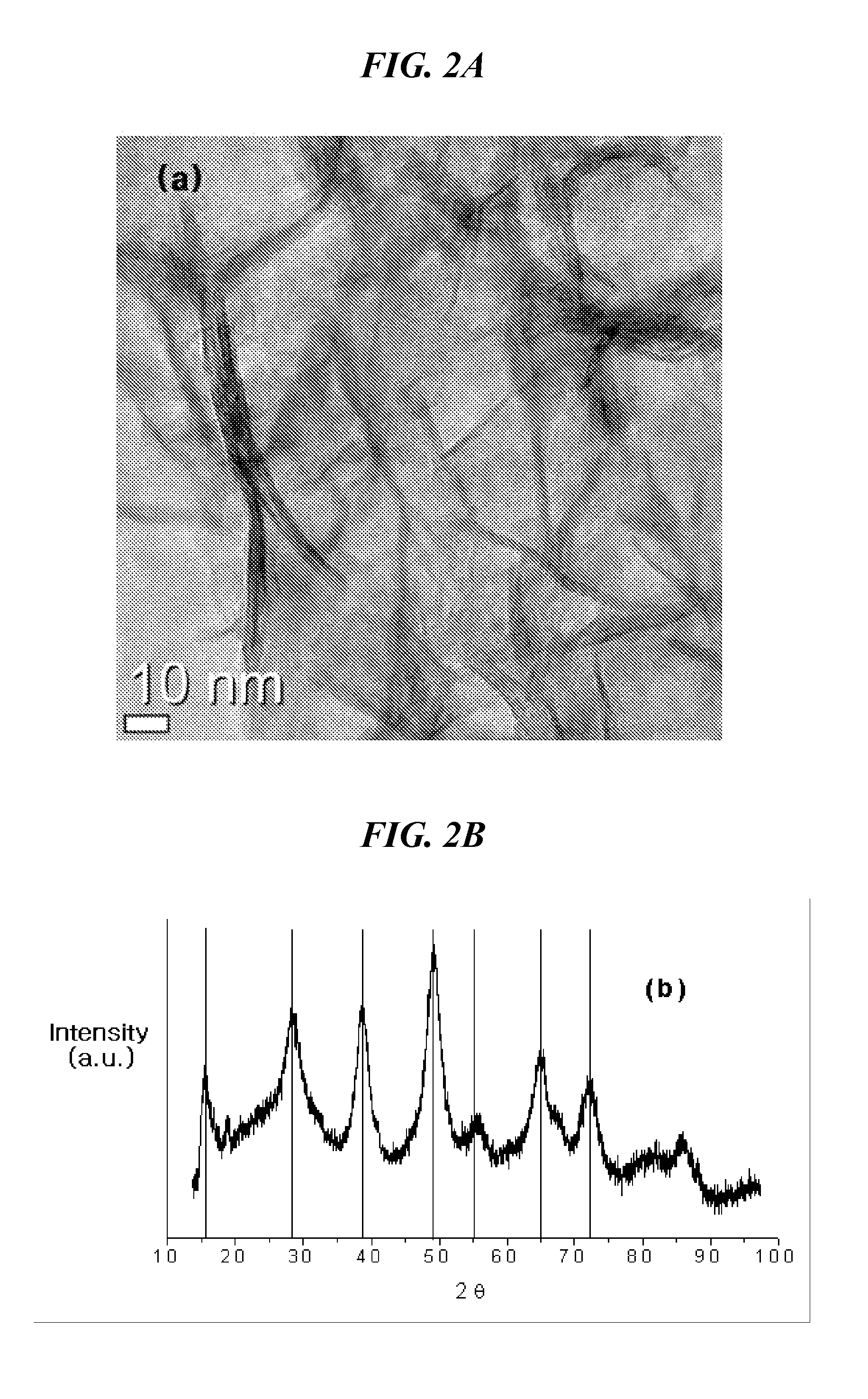

[0063]A mixture solution comprising 7 g of aluminum isopropoxide (AIP), 40 ml of ethylalcohol, 10 ml of water, and 25 μl of HCl was sonicated for 1 hour and stirred at about 90° C. for 3 hours, after which the reaction product was diluted with ethanol and filtered to prepare boehmite nanofibers as powdery nano-alumina. The TEM image and the XRD pattern of the boehmite nanofibers are shown in FIGS. 2A and 2B, respectively,

example 2

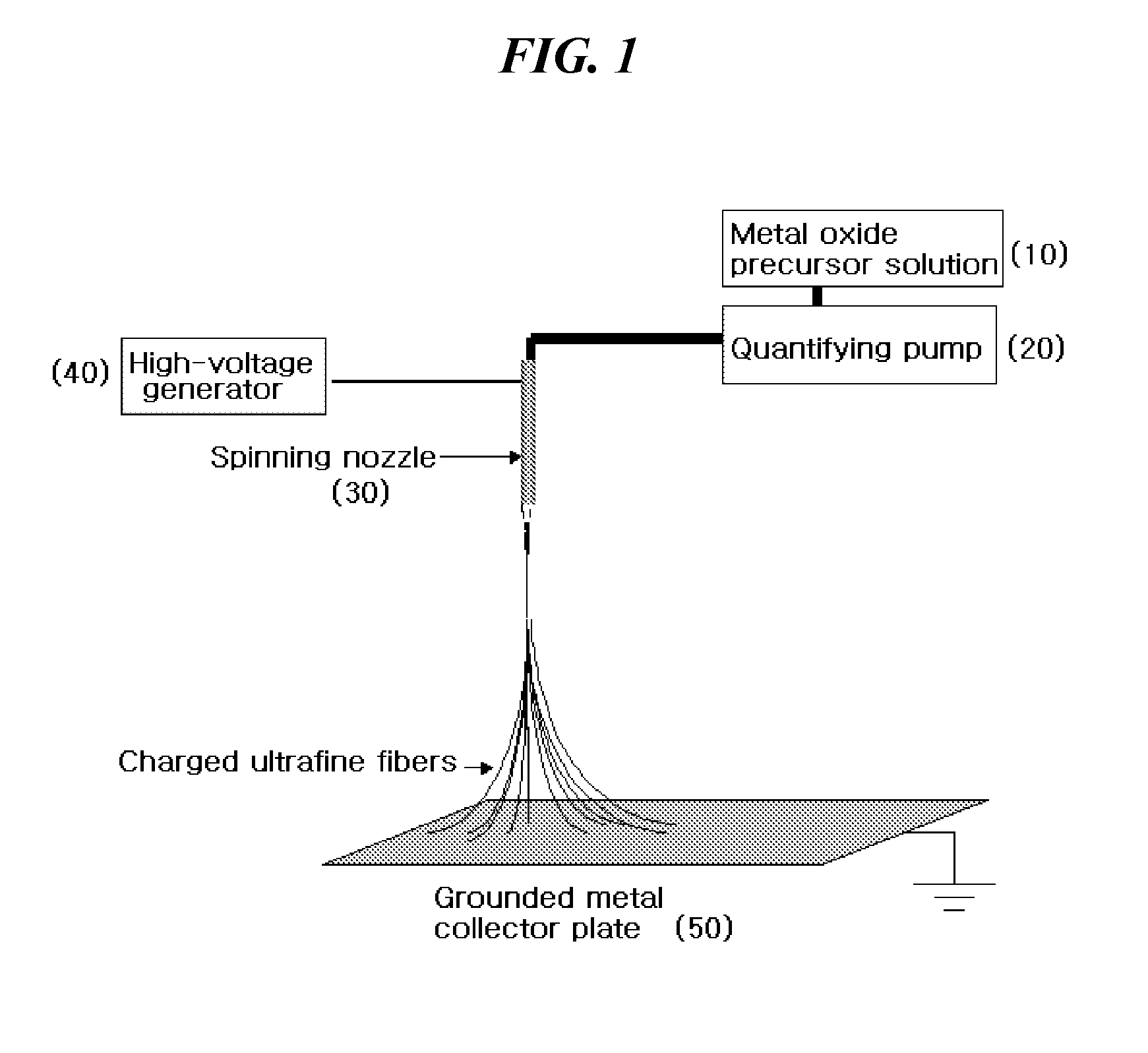

[0066]6 g of the powdery boehmite nanofibers of Example 1 was mixed with the TEOS solution of Comparative Example 1, and 0.12 g of polyvinylpyrrolidone (PVP, mw 1,300,000) was added thereto to prepare a homogeneous mixture solution, which was then discharged at a rate of 20 μl / min under a high-voltage electric field of 20 kV using the 27 G spinning nozzle of the electrospinning device of FIG. 1, to obtain a layer of continuous ultrafine fibers randomly arranged having an average diameter of 230 nm. The ultrafine fibers were heat compressed at 100° C., and sintered at about 300° C., thereby manufacturing a porous body comprising silica / boehmite ultrafine fibers having an average fiber diameter of 100 nm (minimum 85 nm˜maximum 250 nm) with a porosity of 76% and a pore size of 0.8 μm. This fibrous porous body had 53.5 wt % boehmite based on the total weight of the porous body.

[0067]Using the porous body as the filtering layer of the filter, the filtering precision and the permeation fl...

example 3

[0068]A mixture (molar ratio of aluminum nitrate:aluminum isopropoxide:TEOS=3:9:4) comprising 15 g of aluminum isopropoxide, 9.4 g of aluminum nitrate, 7 g of TEOS, 40 ml of ethylalcohol, 10 ml of water, and 50 ml of aqueous hydrochloric acid was mixed with 3 g of PVP and stirred at about 70° C. for 2 hours to prepare a mixture solution. This solution was discharged at a rate of 20 μl / min under a high-voltage electric field of 26.5 kV using the 30 G spinning nozzle of the electrospinning device of FIG. 1, to obtain a layer of continuous ultrafine fibers randomly arranged having an average diameter of 151 nm (minimum 100 nm˜maximum 205 nm). The ultrafine fibers were sintered at about 500° C., from which PVP was then removed, thus manufacturing a porous body comprising alumina / silica ultrafine fibers having an average fiber diameter of 85 nm (minimum 55 nm˜maximum 125 nm) with a porosity of 89% and a pore size of 0.4 μm.

[0069]The resulting fibers were impregnated with a solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com