Cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion batteries and preparation method thereof

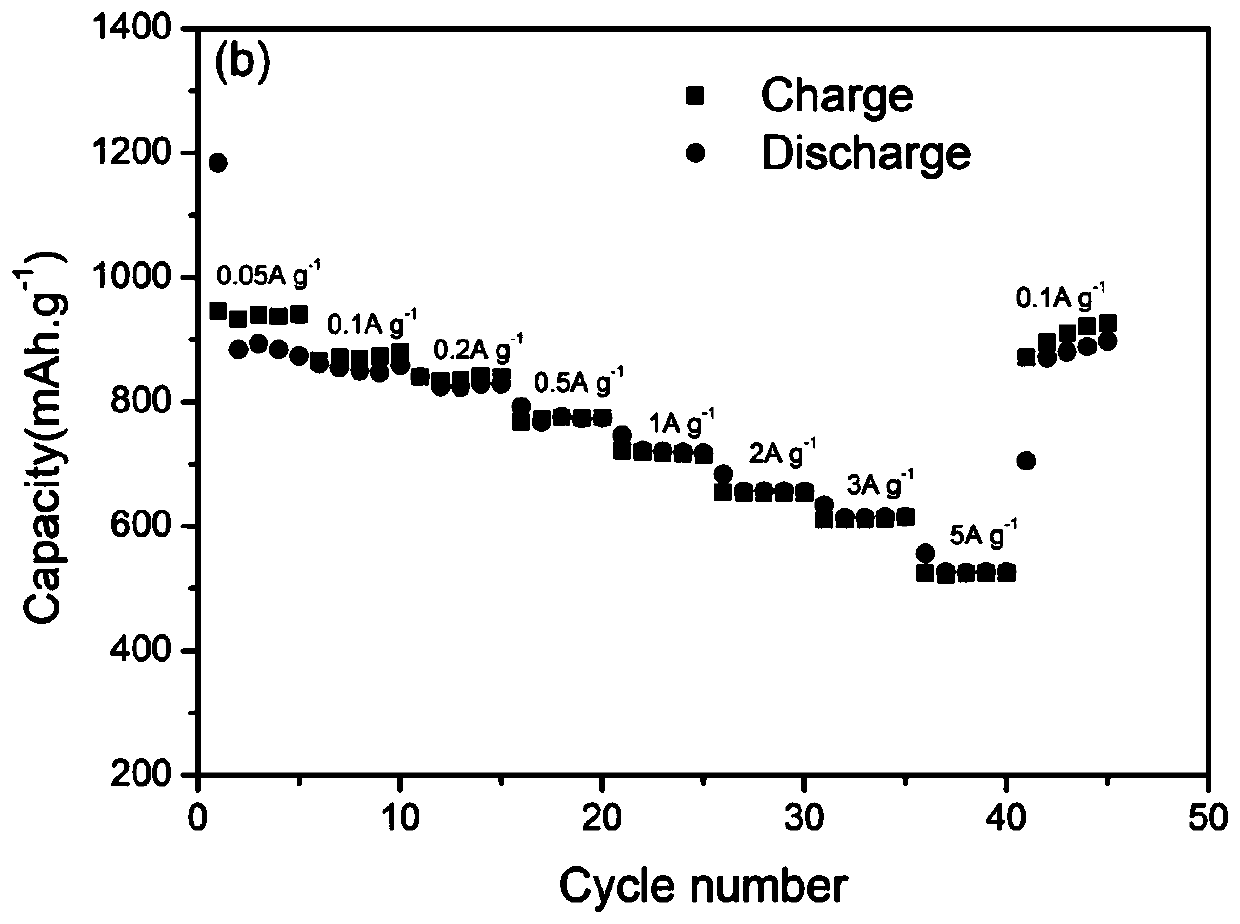

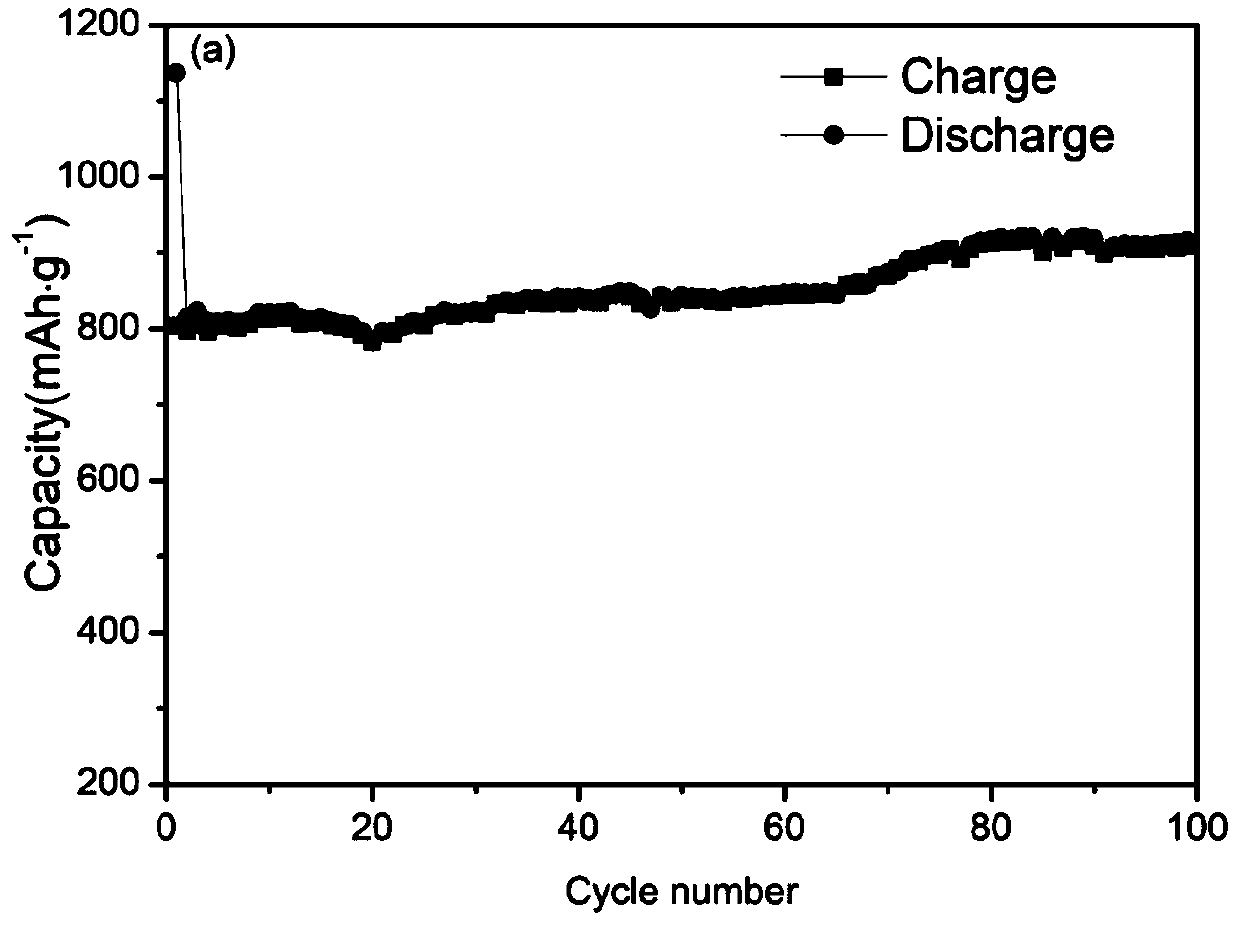

A carbon nanofiber, lithium-ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, active material electrodes, etc. The process is easy to fall off and other problems, so as to achieve good cycle stability, improve electrochemical performance, and improve cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion battery of the present invention comprises the following steps:

[0028] (1) Prepare metal-organic framework ZIF-67 nanoparticles with uniform size by stirring at room temperature;

[0029] (2) Polyacrylonitrile is uniformly dispersed in N,N-dimethylformamide, then the ZIF-67 nanoparticles obtained in the step (1) will be added, stirred and dispersed evenly to obtain the precursor solution of electrospinning, and then As-spun carbon fibers containing polyacrylonitrile and ZIF-67 particles were prepared by electrospinning and collected by a rotating shaft receiver.

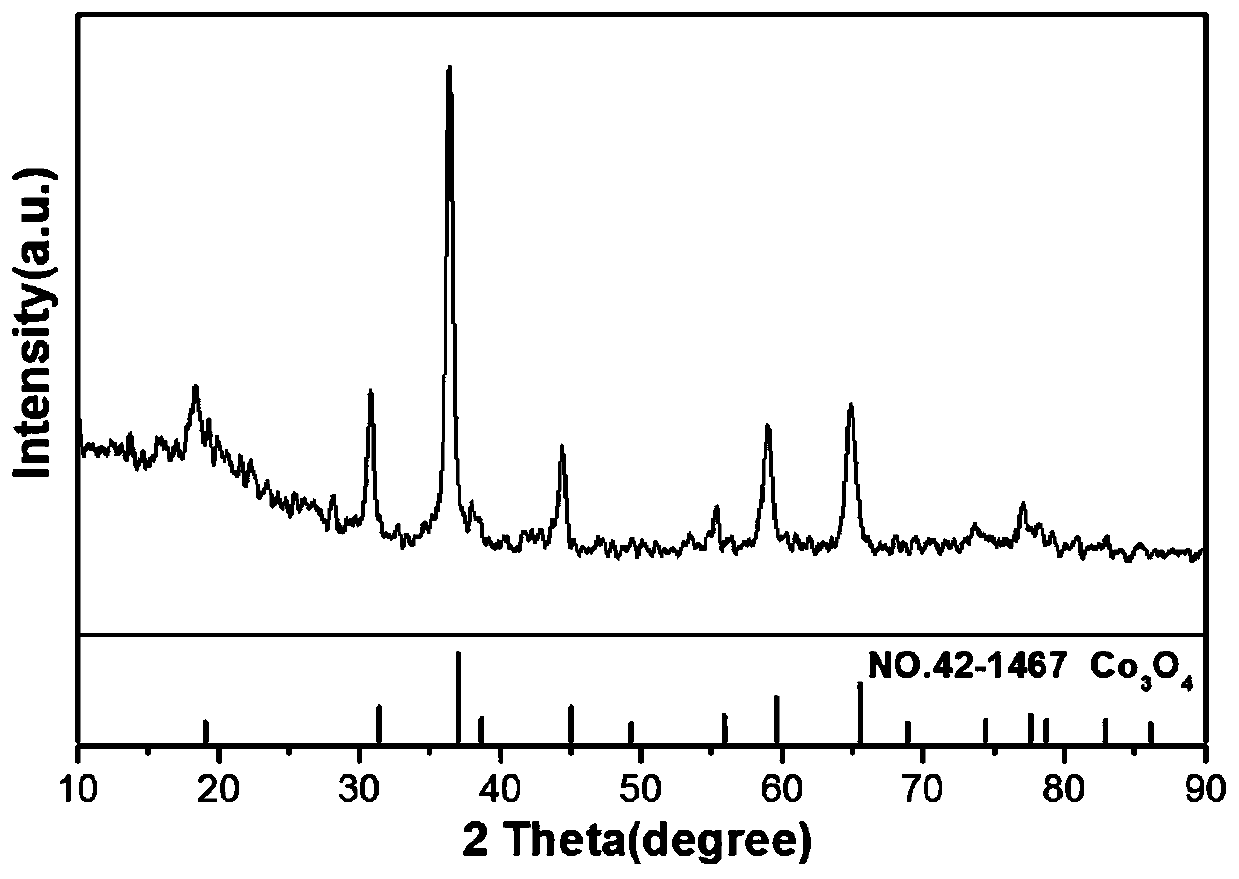

[0030] (3) Pre-oxidize, carbonize and oxidize the as-spun carbon fibers obtained in step (2) to obtain ZIF-67 derived Co 3 o 4 Carbon nanofiber flexible electrode materials.

[0031] In step (1), the preparation process of metal-organic framework ZIF-67 nanoparticles comprises the follo...

Embodiment 1

[0040] Step 1: Dissolve 1.75g of cobalt nitrate hexahydrate in 20mL of ethanol solvent, and dissolve another 1.92g of dimethylimidazole in 20mL of methanol solvent. After the above two solutions are fully stirred until completely dissolved, quickly dissolve the dimethylimidazole The solution was poured into cobalt nitrate solution and stirred vigorously at room temperature. After the reaction is completed, use a high-speed centrifuge to separate to obtain the ZIF-67 material.

[0041] Step 2: Dissolve 0.8g of polyacrylonitrile in 10mL of N,N-dimethylformamide, stir magnetically at 60°C for 6h, and stir until the solution is bright yellow to obtain a PAN solution.

[0042] Step 3: Add 0.2 g of the ZIF-67 material obtained in Step 1 into the PAN solution, stir and dissolve evenly, and obtain an electrospinning precursor solution.

[0043] Step 4: Set the parameters of electrospinning: the voltage is 14kV, the rotational speed of the shaft receiver is 300r / min, the receiving d...

Embodiment 2

[0048] Step 1: Dissolve 1.75g of cobalt nitrate hexahydrate in 20mL of ethanol solvent, and dissolve another 1.92g of dimethylimidazole in 20mL of methanol solvent. After the above two solutions are fully stirred until completely dissolved, quickly dissolve the dimethylimidazole The solution was poured into cobalt nitrate solution and stirred vigorously at room temperature. After the reaction is completed, use a high-speed centrifuge to separate to obtain the ZIF-67 material.

[0049] Step 2: Dissolve 1 g of polyacrylonitrile in 10 mL of N,N-dimethylformamide, stir magnetically at 80° C. for 6 h, and stir until the solution is bright yellow to obtain a PAN solution.

[0050] Step 3: Add 0.5 g of the ZIF-67 material obtained in Step 1 into the PAN solution, stir and dissolve evenly, and obtain the electrospinning precursor solution.

[0051] Step 4: Set the parameters of electrospinning: the voltage is 15kV, the rotational speed of the rotating shaft receiver is 500r / min, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com