Polymer electrospun fibers, preparation method thereof and application thereof

A technology of electrospinning and polymer, which is applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, textile and paper making, which can solve the problems of hindering deposition and waste, and achieve pain relief, simple operation and good liquid absorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Medical dressings are prepared using fibers containing polycaprolactone and / or linear polyethyleneimine.

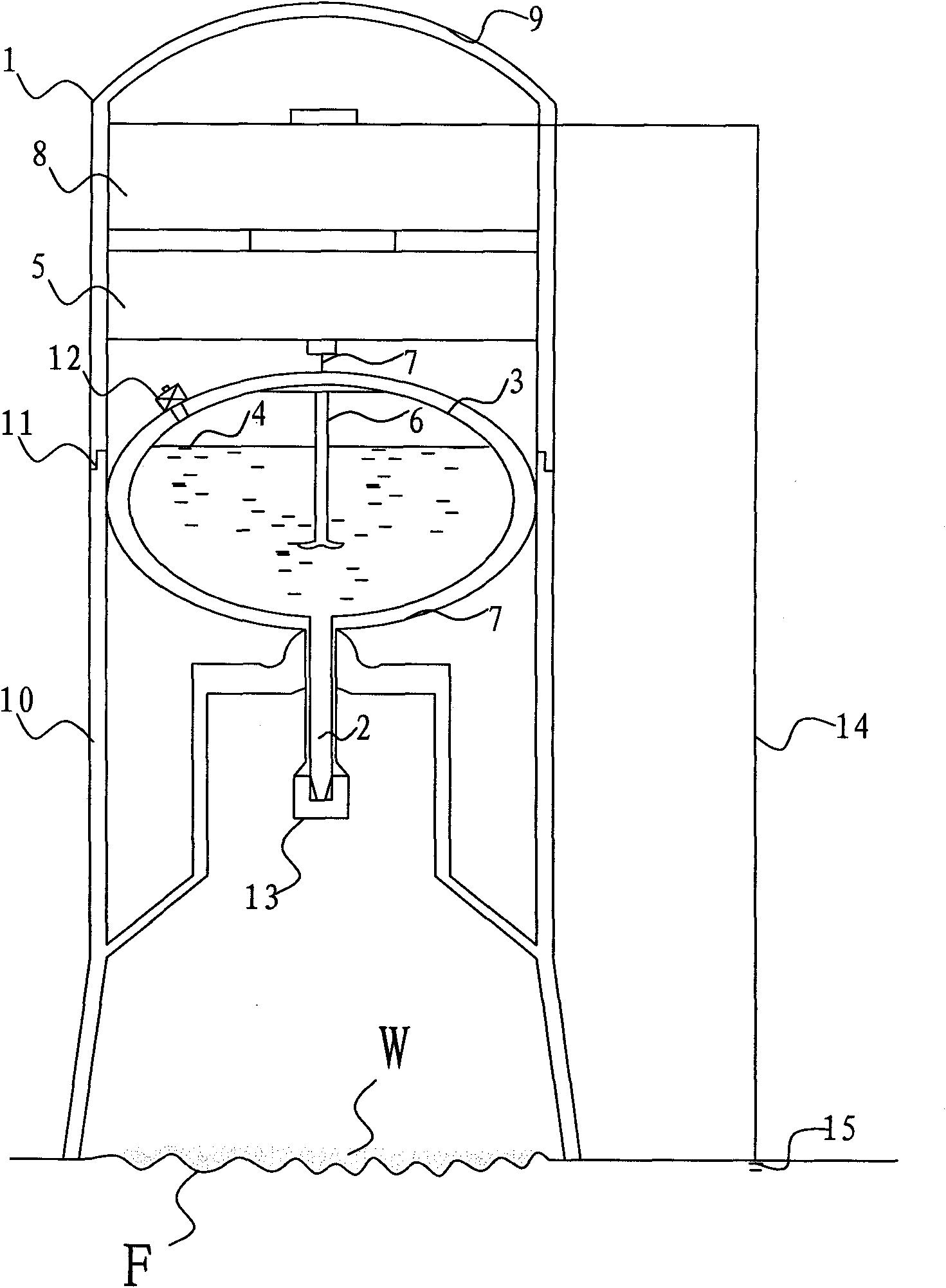

[0076] Polycaprolactone was dissolved in acetone to prepare an 18% (w / w) solution. A 25% (w / w) solution was prepared by dissolving linear polyethyleneimine in ethanol. Samples were prepared by mixing the above solutions. And use a variety of pH adjusters. When alginic acid or Carbopol is used, its mass fraction in the two polymers (polycaprolactone / linear polyethyleneimine) is 2.9% or its mass fraction in the polymer solution (polycaprolactone / linear polyethyleneimine ) at a concentration of 2.9% (w / w) In order to mix the pH adjuster, alginic acid was first dissolved in a small amount of ethanol, followed by a linear polyethyleneimine solution and finally a polycaprolactone solution. The final mixture is immediately spun through the above-mentioned electrospinning device 1 to avoid the aggregation of the pH regulator, and to obtain a medical composite, that is, ...

Embodiment 2

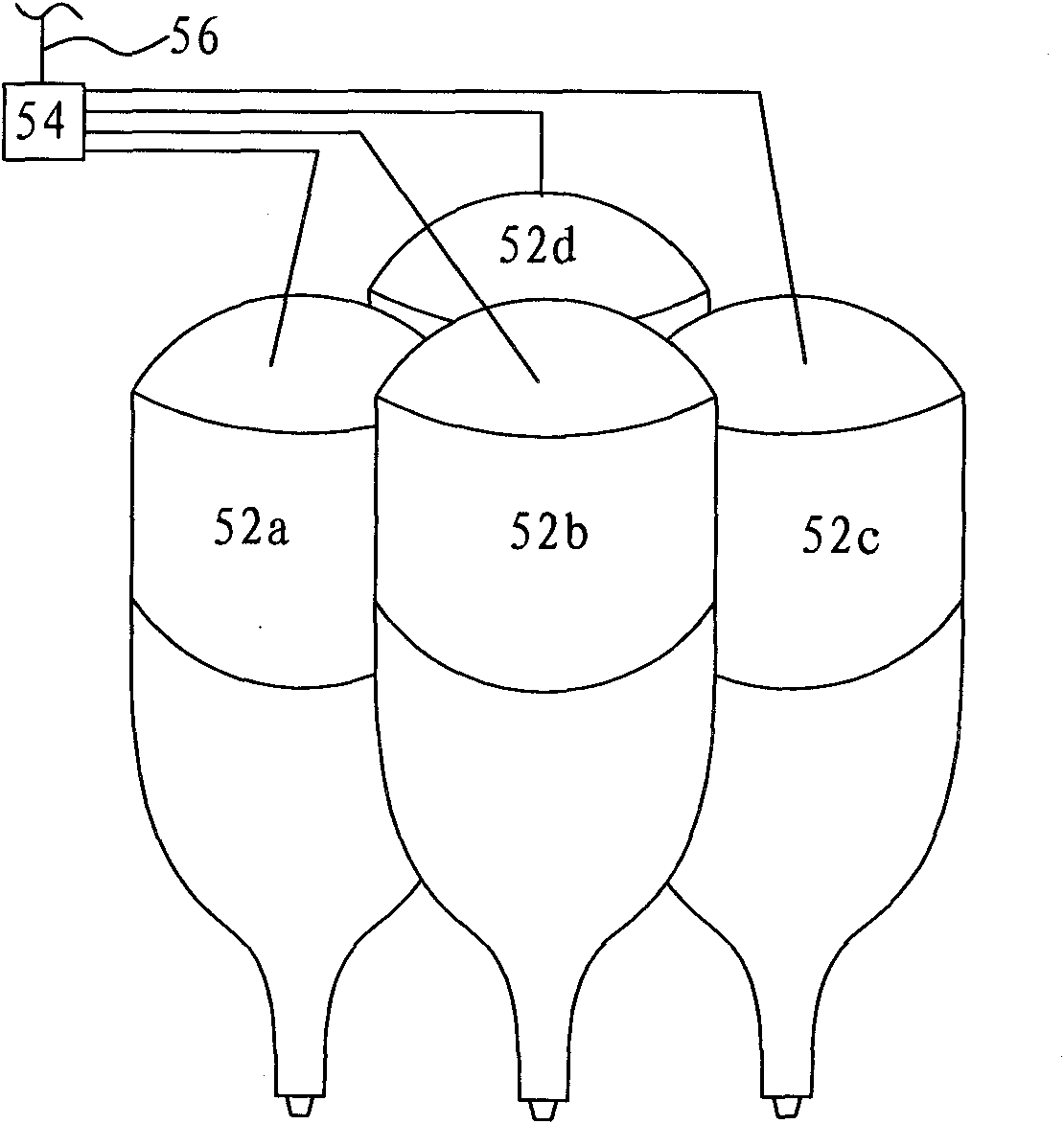

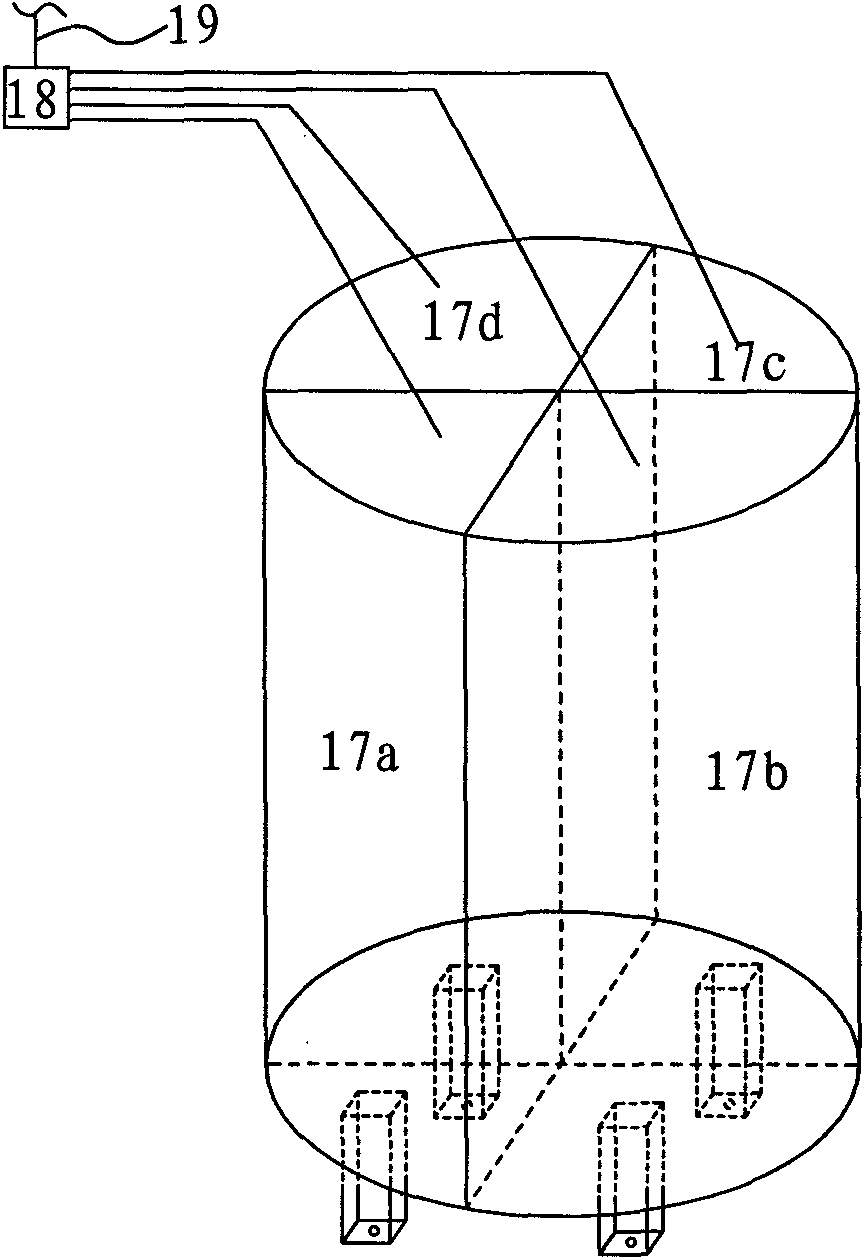

[0102] Fibers are prepared from various composite polymer solutions by adding therapeutic components to the raw material solution.

[0103] Prepare polycaprolactone (PCL) solution, polyhydroxyethylmethacrylate (Poly-HEMA) solution, polyvinylpyrrolidone (PVP) solution, polyethyloxazoline (PEOz) solution, polyoxyethylene (PEO) solution, And linear polyethyleneimine (L-PEI) solution, by adding different therapeutic components to it, forming a variety of composite polymer solutions to make fibers.

[0104] When preparing polycaprolactone (PCL) solution, first add 12.29g polycaprolactone (PCL) and 50g acetone in the beaker, heat until dissolving, after the polymer dissolves, the solution is stirred and cooled to room temperature, then in the sample Add acetone to make the mass percent concentration of polycaprolactone (PCL) in acetone reach 16%.

[0105] When preparing polyethyloxazoline (PEOz), polyoxyethylene (PEO), and polyvinylpyrrolidone (PVP) solutions, take the same steps a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com