A thin sheet micro-nano(k,na)nbo 3 Crystal and its preparation method

A micro-nano and thin-sheet technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficult control of reaction time, KNN purity and thickness, many intermediate phases produced, unfavorable mass production, etc., to achieve excellent chemistry Stability, narrow particle size distribution, effect of increasing surface potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 30ml of ethylene glycol as a solvent, then add 5.88g KOH, 1.8g NaOH, 3g Nb 2 o 5 Stir slowly with a glass rod until the solute is completely dissolved, then put it on a magnetic stirrer and stir for 30 minutes, then pour it into a hydrothermal kettle, heat it in water at 180°C for 8 hours, centrifuge at 8000r / min for 3 minutes, and then use distilled water and no Wash twice with water and ethanol, and dry in an oven at 60°C to obtain flaky micro-nano (K, Na)NbO 3 Crystal powder.

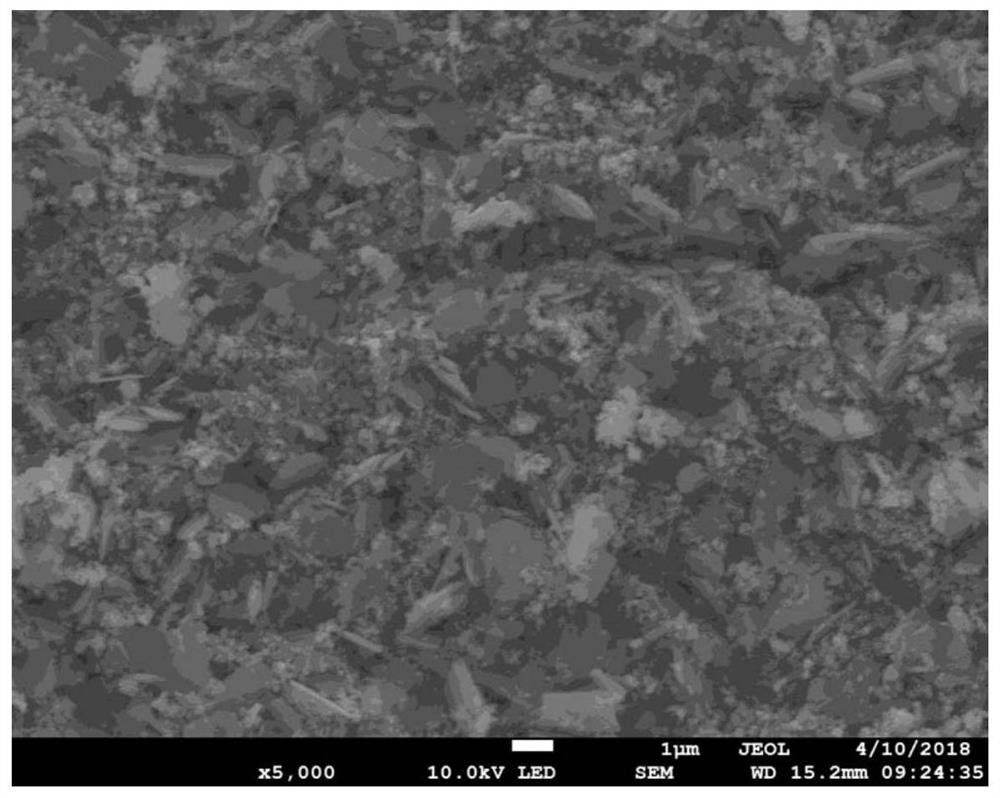

[0026] figure 1 (K, Na)NbO in this example 3 Scanning electron microscope image of the powder, it can be seen that the product (K, Na)NbO 3 It is based on ultra-thin micro-nano (K, Na) NbO with a diameter of 1-2 μm 3 The crystals are the main ones, and the dispersion is good; in addition, there are also nanoparticles scattered around, and some of them are agglomerated.

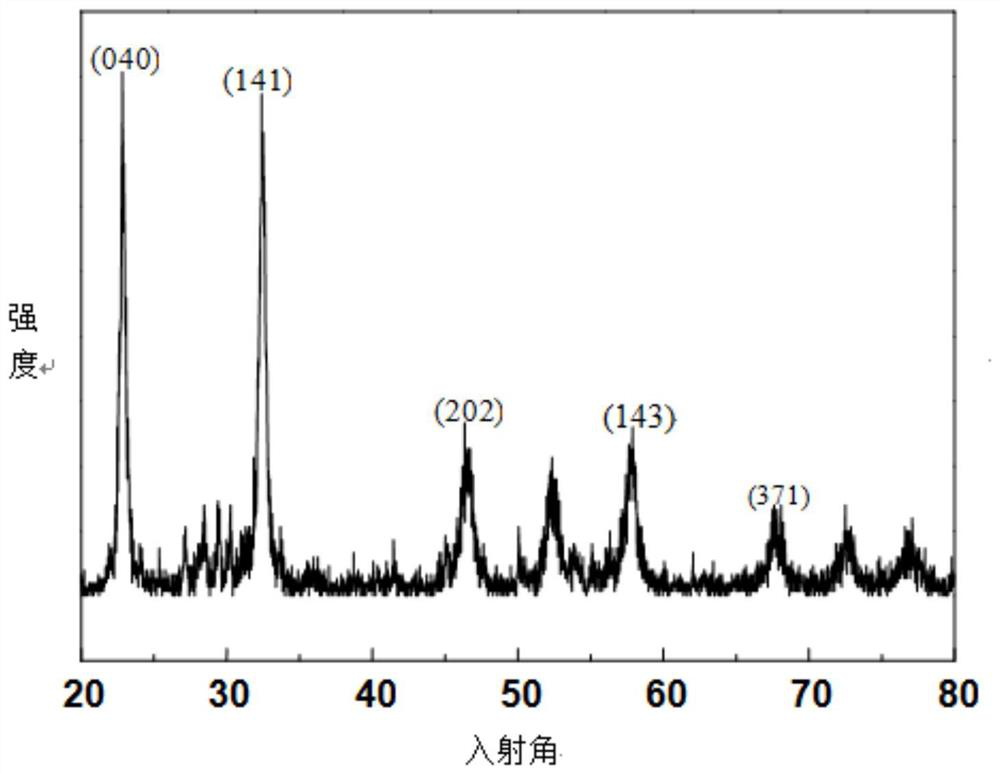

[0027] figure 2 (K, Na)NbO in this example 3 The XRD pattern of the powder, it can be seen that the ultra-thi...

Embodiment 2

[0029] Weigh 30ml of ethylene glycol as a solvent, then add 5.88g KOH, 1.8g NaOH, 1.5g Nb 2 o 5 Stir slowly with a glass rod until the solute is completely dissolved, then put it on a magnetic stirrer and stir for 30 minutes, then pour it into a hydrothermal kettle, heat it in water at 200°C for 8 hours, centrifuge at 8000r / min for 3 minutes, and then use distilled water and no Wash twice with water and ethanol, and dry in an oven at 60°C to obtain flaky micro-nano (K, Na)NbO 3 Crystal powder.

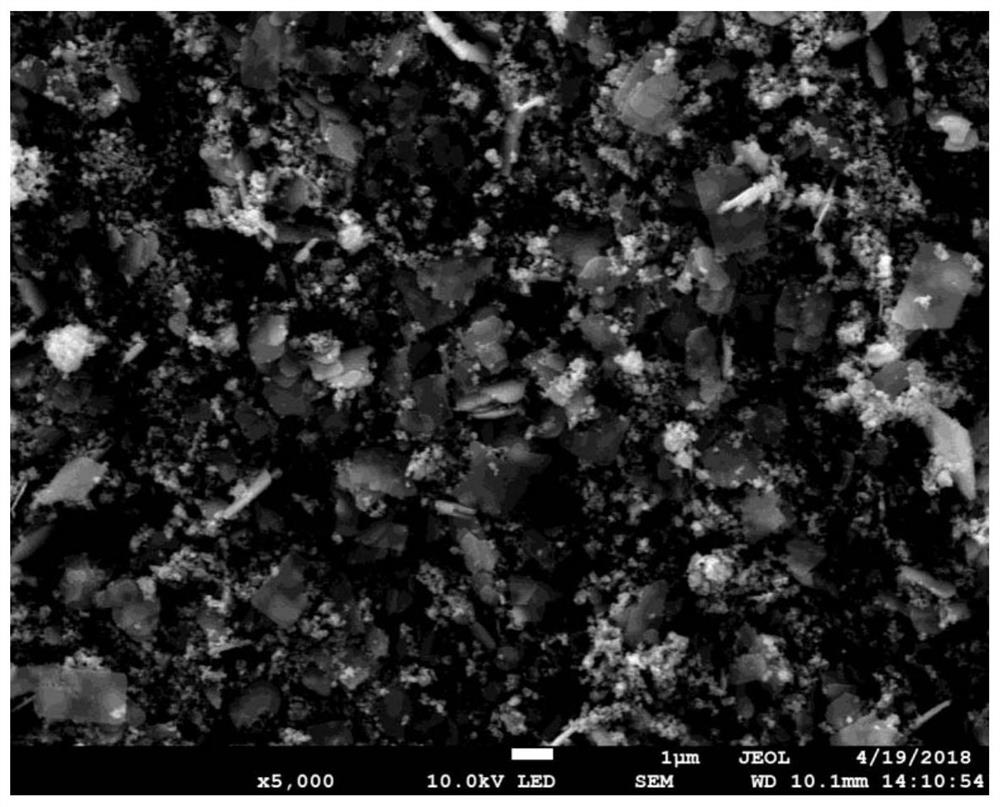

[0030] image 3 (K, Na)NbO in this example 3 The scanning electron microscope picture of the powder, it can be seen that the obtained product (K, Na) NbO 3 It is mainly flakes with a diameter of 0.8-1.5 μm. In addition, there are nanoparticles scattered around, and some of them are agglomerated. Compared with Example 1, the flakes obtained under this condition have a smaller particle size .

Embodiment 3

[0032] Weigh 30ml of ethylene glycol as a solvent, then add 5.88g KOH, 1.8g NaOH, 1.5g Nb 2 o 5 , 0.5wt% surfactant PEG, slowly stirred with a glass rod until the solute was completely dissolved, then placed it on a magnetic stirrer and stirred for 30min, then poured it into a hydrothermal kettle, and heated it at 200°C for 8h, 8000r / min centrifuged for 3min, then washed twice with distilled water and absolute ethanol, and dried in an oven at 60°C to obtain ultra-thin flaky micro-nano (K, Na)NbO 3 Crystal powder.

[0033] Figure 4 (K, Na)NbO in this example 3 The scanning electron microscope picture of the powder, it can be seen that the obtained product (K, Na) NbO 3 It is quite different from Example 1 and Example 2, but it is basically composed of flakes, with a particle size of about 1 μm and a slight thickness. In addition, there are products with a honeycomb shape composed of agglomerated nanoparticles Adheres to flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com