A kind of reduced graphene oxide/nano zirconia composite adsorption dephosphorization agent and its preparation method

A nano-zirconia, composite adsorption technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of secondary water pollution, low phosphorus removal efficiency, poor sedimentation, etc. Adsorption capacity, high adsorption efficiency, effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, which is made of the following raw materials in parts by weight:

[0051] Raw material parts by weight

[0052] Graphene oxide 2

[0053] Nano Zirconium Dioxide 2.

[0054] A preparation method of reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, the steps are:

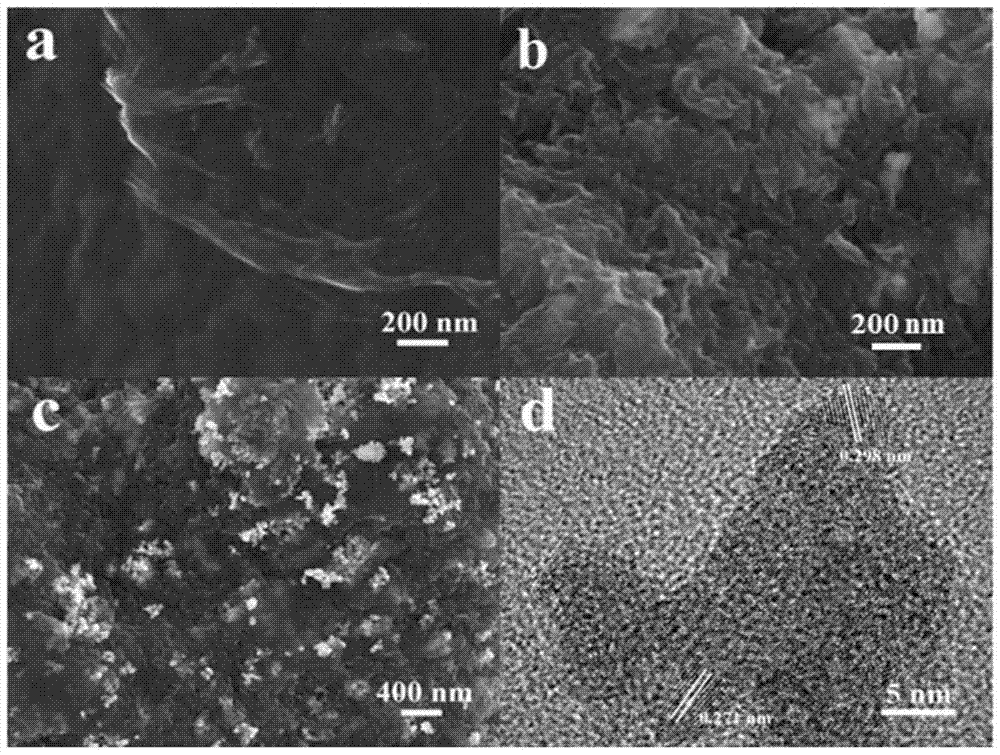

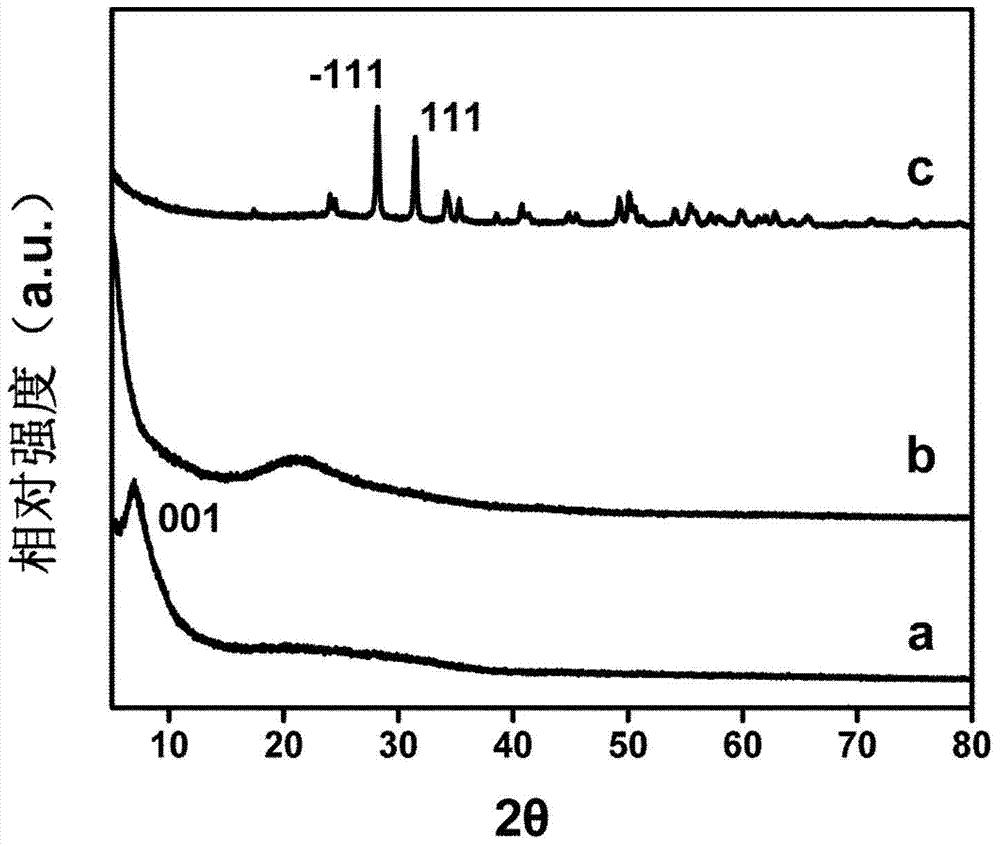

[0055] a. Prepare graphene oxide from graphite powder: Weigh 6g of graphite powder and place it in a dry beaker, then add 24mL of 98% concentrated sulfuric acid, stir in a water bath at 80°C, then slowly add 5g of potassium persulfate and 5g of phosphorus pentoxide in sequence , after continuous stirring for 5 h, cooled to room temperature, added 1 L of deionized water for dilution, and left overnight. Filter the powder with a 0.2 micron microporous membrane, wash with deionized water three to five times until the solution becomes neutral, and dry the powder at 70°C. Transf...

Embodiment 2

[0058] A reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, which is made of the following raw materials in parts by weight:

[0059] Raw material parts by weight

[0061] Nano Zirconium Dioxide 4.

[0062] A preparation method of reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, the steps are:

[0063] a. graphene oxide preparation method is identical with embodiment 1.

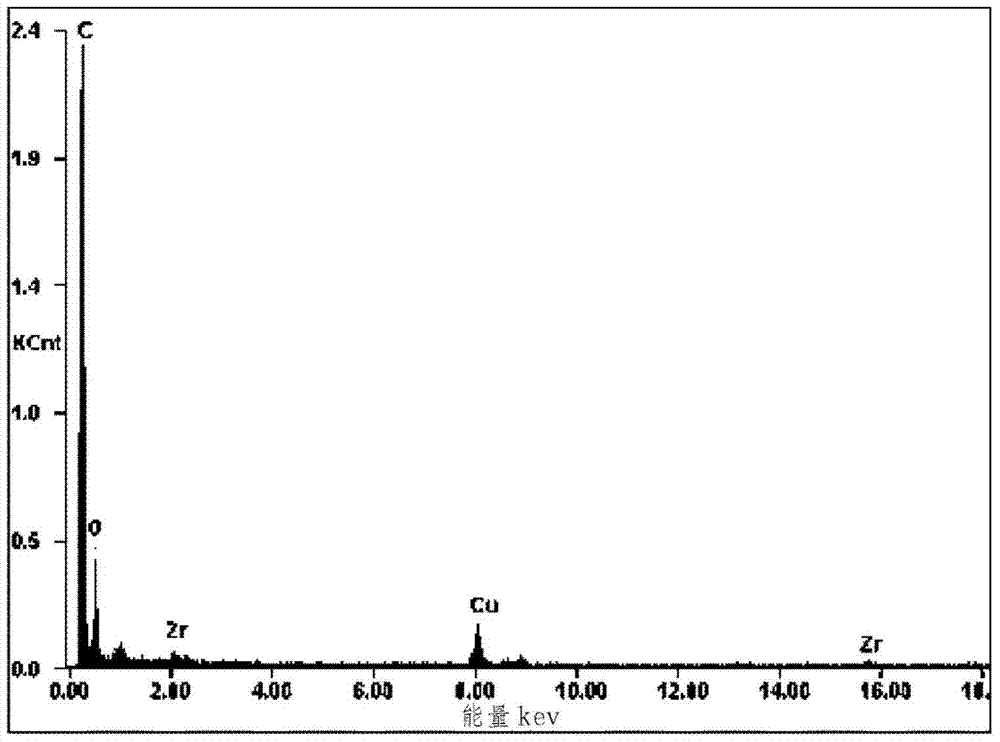

[0064] b. Preparation of reduced graphene oxide / nano-zirconia composite material: ultrasonically disperse the prepared graphene oxide in deionized water to prepare a 1 g / L graphene oxide dispersion. Add 0.02 g nanometer zirconia to 15 mL of 1 g / L graphene oxide solution, stir for 2 h, transfer the suspension to a 100 mL hydrothermal kettle, and let it react at 150 °C for 5-6 h. The obtained solid was washed 3-4 times with deionized water, and dried in a vacuum drying oven at 60°C for 12 hours. The...

Embodiment 3

[0066] A reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, which is made of the following raw materials in parts by weight:

[0067] Raw material parts by weight

[0068] Graphene oxide 5

[0069] Nano Zirconium Dioxide 6.

[0070] A preparation method of reduced graphene oxide / nano zirconium dioxide composite adsorption dephosphorization agent, the steps are:

[0071] a. graphene oxide preparation method is identical with embodiment 1.

[0072] b. Preparation of reduced graphene oxide / nano-zirconia composite material: ultrasonically disperse the prepared graphene oxide in deionized water to prepare a 1 g / L graphene oxide dispersion. Add 0.06 g nanometer zirconia to 25 mL of 1 g / L graphene oxide solution, stir for 2 h, transfer the suspension to a 100 mL hydrothermal kettle, and let it react at 150 °C for 5-6 h. The obtained solid was washed 3-4 times with deionized water, and dried in a vacuum drying oven at 60°C for 12 hours. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com