Gasification method of waste textile fabrics

A textile and waste technology, applied in the field of solid waste energy utilization and carbon dioxide emission reduction, can solve problems such as obstacles to scientific utilization of waste textiles, lack of pertinence and systematization, and achieve mitigation of climate deterioration. The effect of lowering reaction temperature and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

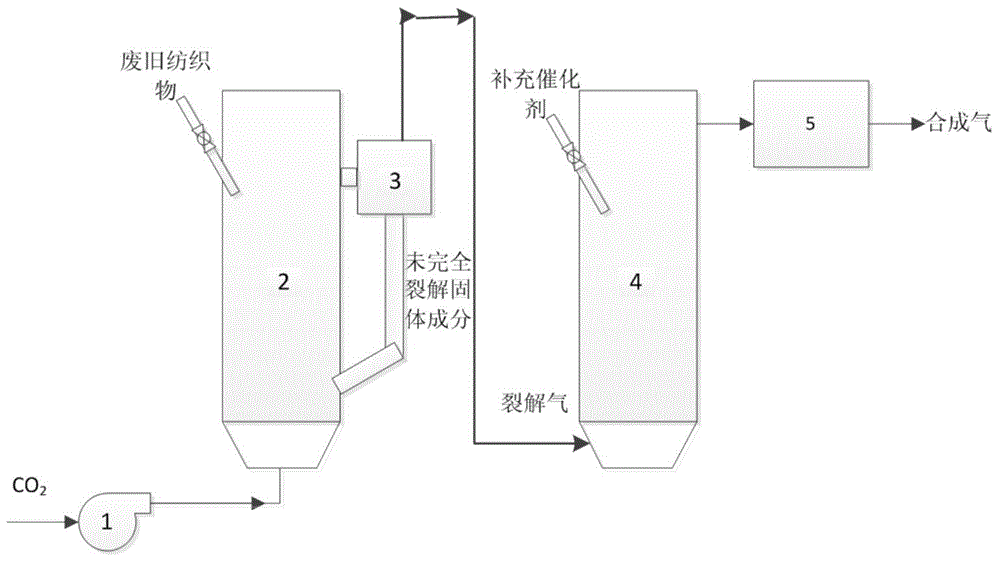

Method used

Image

Examples

example 1

[0024] Add waste textiles to the pyrolysis reactor at 100kg / h, CO 2 as carrier gas with 10m 3 / h into the cleavage reactor. The cracking reaction is carried out at 300°C, and the cracked gas product enters the gasification reactor, and 100kg of iron carbonate is placed in the gasification reactor as a catalyst, and the gasification reaction is carried out at 800°C, and the residence time is 10s. The gas product is passed into the gas purification device to obtain clean synthesis gas (CO and H 2 ).

example 2

[0026] Add waste textiles to the pyrolysis reactor at 100kg / h, CO 2 as carrier gas with 10m 3 / h into the cleavage reactor. The cracking reaction is carried out at 400°C, and the cracked gas product enters the gasification reactor, and 100kg of calcium carbonate is placed in the gasification reactor as a catalyst, and the gasification reaction is carried out at 900°C, and the residence time is 20s. The gas product is passed into the gas purification device to obtain clean synthesis gas (CO and H 2 ).

example 3

[0028] Add waste textiles to the pyrolysis reactor at 100kg / h, CO 2 as carrier gas with 10m 3 / h into the cleavage reactor. The cracking reaction is carried out at 400°C, and the cracked gas product enters the gasification reactor, and 100kg of potassium carbonate is placed in the gasification reactor as a catalyst, and the gasification reaction is carried out at 1000°C, and the residence time is 30s. The gas product is passed into the gas purification device to obtain clean synthesis gas (CO and H 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com