Process for recycling bismuth concentrate from tungsten ore magnetic separation tailings

A technology for magnetic separation of tailings and bismuth concentrate, which is applied in flotation, solid separation and other directions, can solve the problems of insufficient technological process, insufficient grade and recovery rate of bismuth concentrate, and can improve the degree of monomer dissociation and widen the recovery. The effect of a wide range of routes and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

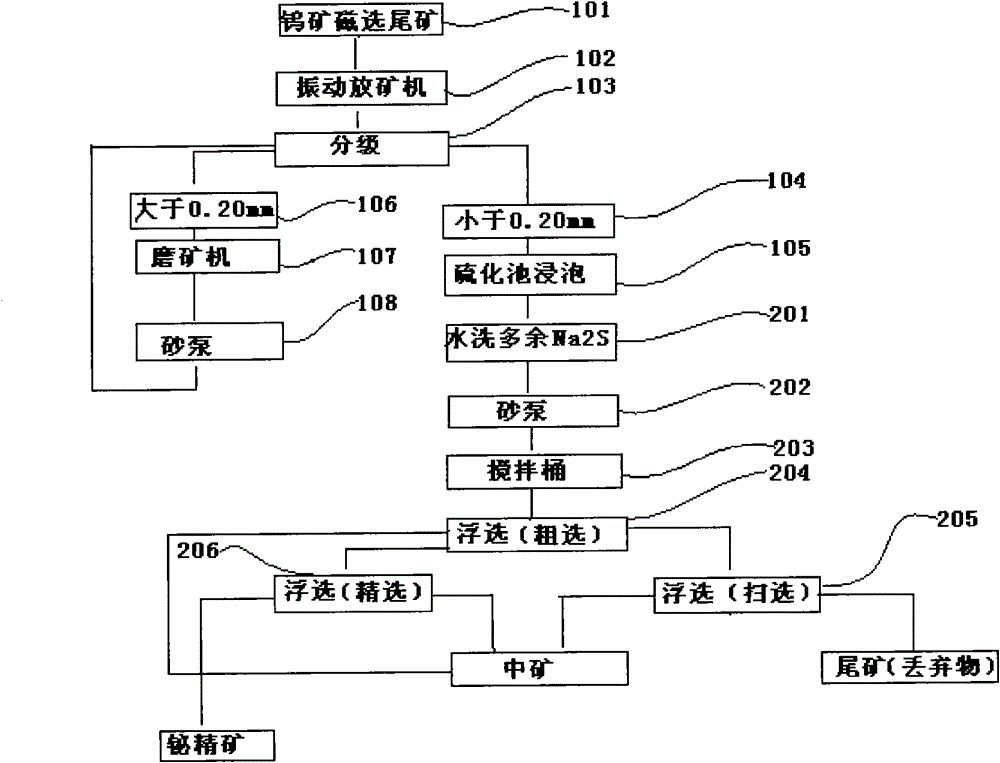

[0035] Such as figure 1 As shown, according to the process of reclaiming bismuth concentrate from tungsten ore magnetic separation tailings according to the present invention, take tungsten ore magnetic separation tailings as raw material, and the main steps include:

[0036] 1. Classification (grinding) process

[0037] From the tungsten ore magnetic separation workshop, the magnetic separation tailings are transferred by driving, transported by car to the raw material warehouse 101 of the flotation workshop, and the raw materials are sent to the high-frequency vibrating screen 103 for classification by the vibrating ore feeding machine 102, and the 0.2mm undersize 104 is a qualified particle size, which is sent to the sodium sulfide soaking tank 105, and the +0.2mm oversize 106 is sent to the ore grinding machine 107, and is returned to the high-frequency vibrating screen 103 by the sand pump 108 after being ground.

[0038] In particular, from the measurement results of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com