Concentration method for qualifying headings and increasing recovery rate

A process method and technology of recovery rate, applied in the field of indicators, can solve the problems of low economic benefit of mines, poor sorting effect, waste of non-renewable mineral useful resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

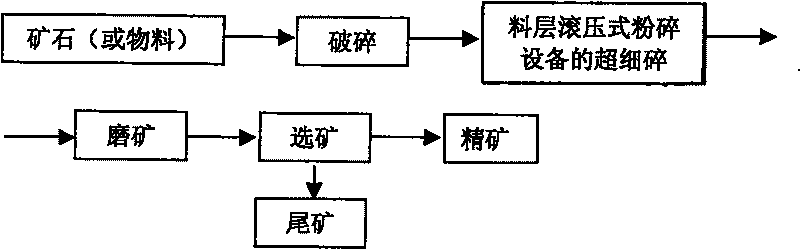

[0015] as attached figure 1 As shown, after the ore is crushed, the material layer rolling crushing equipment is used for ultra-fine crushing (or coarse grinding), and the ball mill (one-stage or multi-stage grinding) is used for grinding, and other grinding equipment can also be used for the grinding machine. After grinding, the fine-grained ore is beneficiated. When the ore (or material) has a small particle size, no crushing process is required.

Embodiment 2

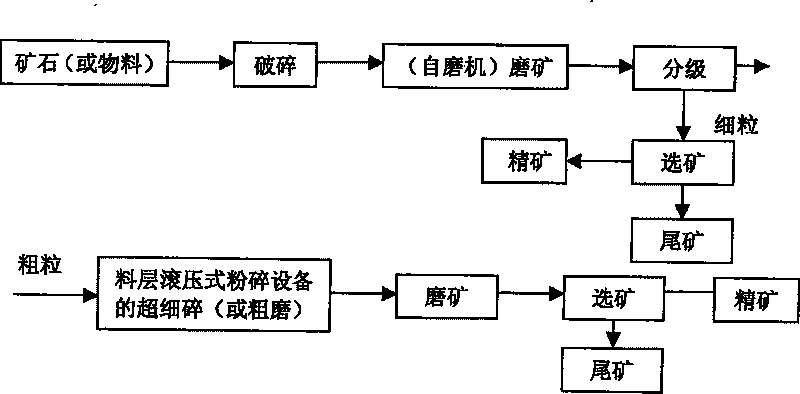

[0017] as attached figure 2 As shown, after the ore is crushed, an autogenous mill is used as a one-stage grinding (a ball mill can also be used for one-stage grinding). Ball mill (one-stage or multi-stage grinding), the mill can also use other grinding equipment, and fine-grained ore is beneficiated after grinding.

Embodiment 3

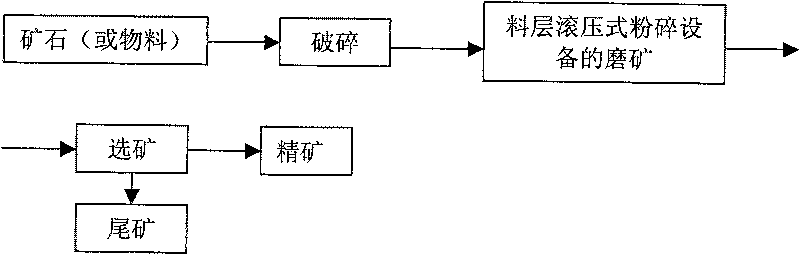

[0019] as attached image 3 As shown, after the ore is crushed, the material layer rolling crushing equipment is directly used as the grinding equipment, and then the fine-grained ore is directly beneficiated. When the ore (or material) has a small particle size, no crushing process is required.

[0020] The above three drawings only express three main technological processes. According to different conditions on site, different and complicated technological processes can be made correspondingly. No crushing process is required, in the attached figure 1 Among them, the ore grinding process can also be 1-3 stage grinding process, but when it is used for ultra-fine crushing, it is only necessary to configure the material layer rolling crushing equipment in front of one of the stage grinding equipment. In the above process flow, only the main process is expressed, and other processes such as classification and transportation are not expressed.

[0021] In the crushing process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com