Combined process for recovering antimony, lead and gold from multi-metal tailings

A combined process and multi-metal technology, which is applied in the combined process of lead and gold, and the field of antimony recovery, can solve the problems of gangue mineral mechanical entrainment aggravation, high slime content, and difficult recovery of valuable elements, so as to save chemicals and electricity consumption, shorten the flotation process, and eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

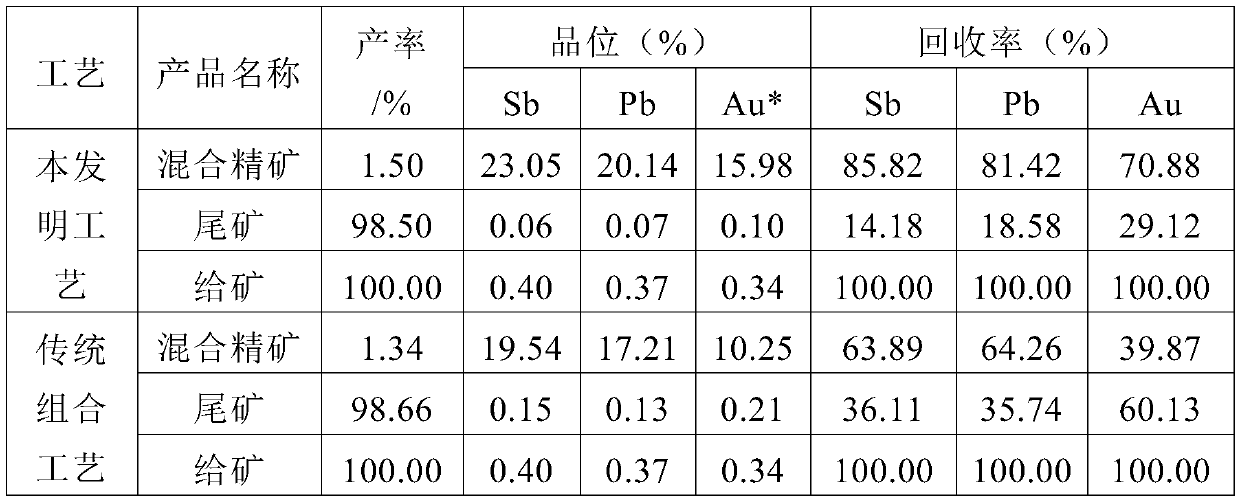

[0023] In the tailings of a polymetallic mine in Weixi, Yunnan, Sb 0.40%, Pb 0.37%, S1.06%, Au 0.34g / t. The main metal minerals are pyrite, stibnite and galena; the main gangue minerals are quartz, calcite, potassium feldspar and sericite. The ore structure mainly includes porphyritic structure, microscopic scale structure, heteromorphic granular structure, fine granular structure, inclusion structure and so on.

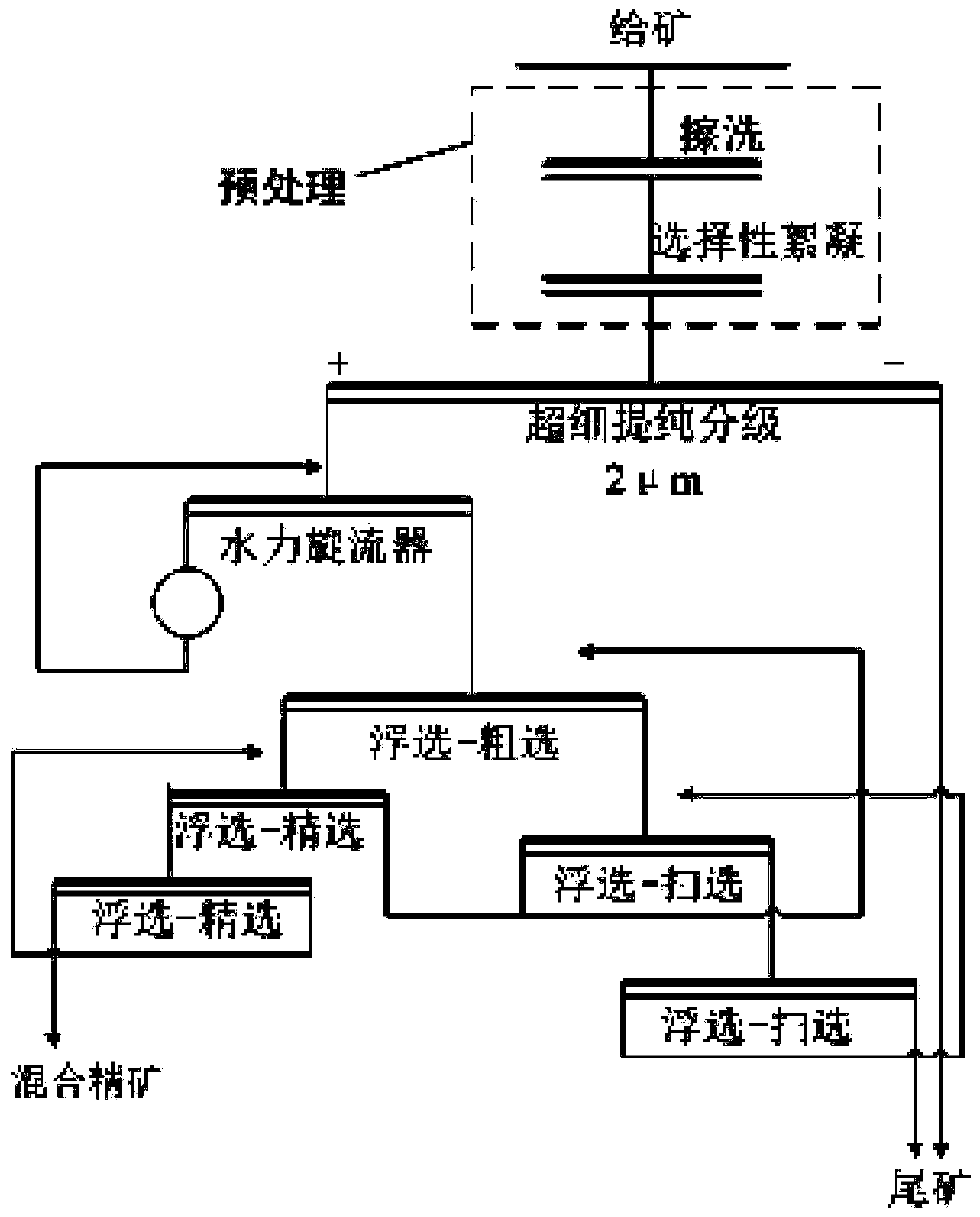

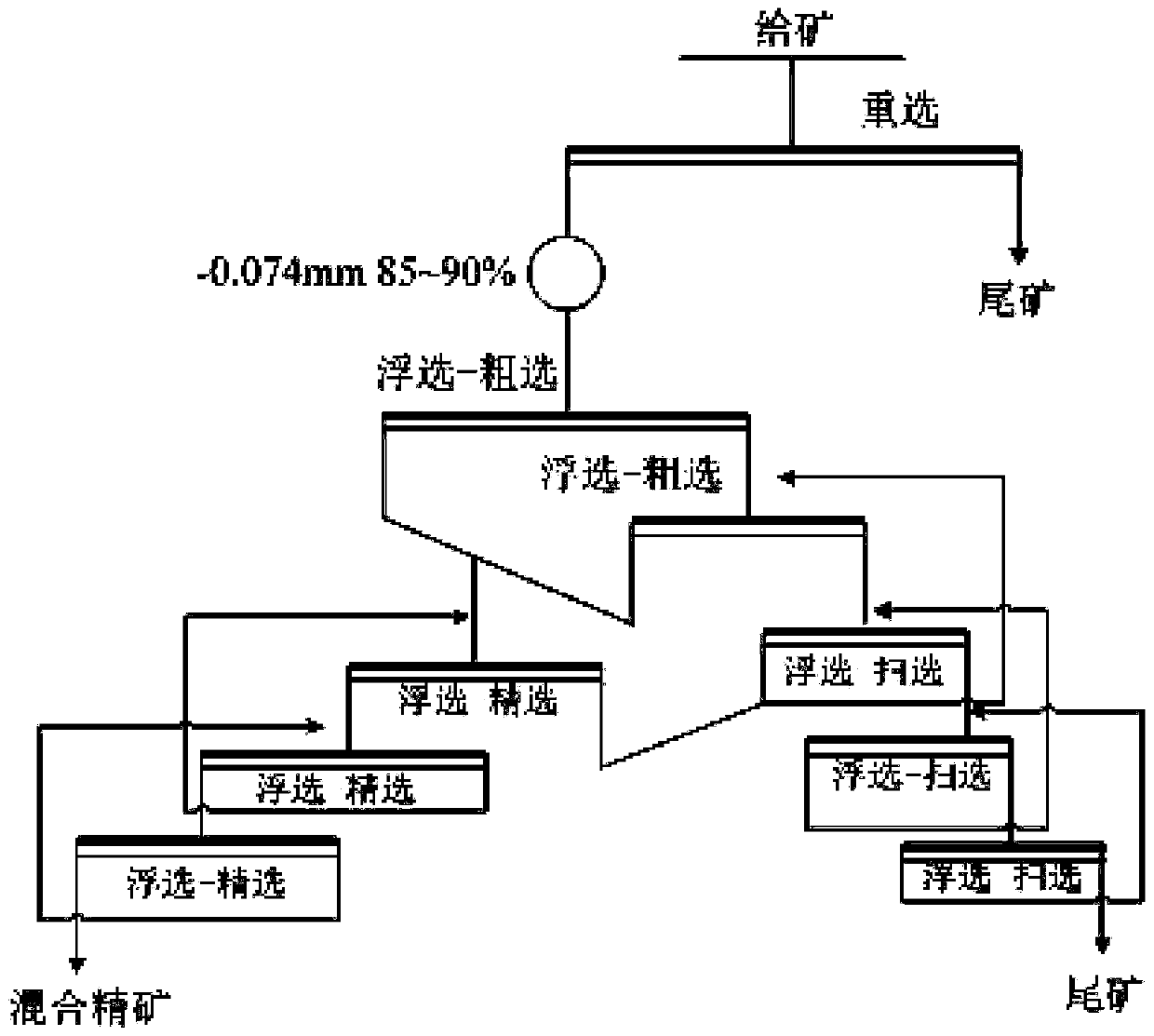

[0024] Using the process of the present invention, the tailings material is slurried and scrubbed in the mixing tank, the stirring concentration is 15% (weight ratio), and the stirring intensity is 1700r / min; adding hydrolyzed polyacrylamide and sodium fluoride (weight ratio is 3: 1), the total dosage of the agent is 16g / t, and the ultrafine purification classifier is used for desliming, the concentration is 10% (weight ratio), and the working pressure is 0.70MPa; the grit enters the hydrocyclone for classification, and the hydrocyclone The underflow is ground by a ...

Embodiment 2

[0030] Tailings of a polymetallic mine in Xiangxi, Hunan, the tailings mainly include pyrite, arsenopyrite, stibnite, galena, wheel ore, etc.; the gangue minerals are mainly quartz, sericite, calcite, chlorite, kaolin Wait. Sb 0.60%, Pb 0.51%, S 2.42%, Au 0.36g / t in the ore.

[0031] Utilizing the process of the present invention, the tailings material is slurried and scrubbed in the mixing tank, the stirring concentration is 15% (weight ratio), and the stirring intensity is 2200r / min; Fine purification and classifier desliming, the concentration is 12% (weight ratio), working pressure is 0.75MPa; the sand settling enters the hydrocyclone for classification, and the underflow of the hydrocyclone is ground by a ball mill, and the grinding fineness is -0.038 μm 82%, hydrocyclone overflow for flotation, before flotation, adjust the slurry concentration to 33% (weight ratio), adjust the pH to 7.5 with sodium carbonate, the dosage of sodium carbonate is 500g / t, activator copper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com