Aluminum-lithium alloy casting adopting shell to inhibit interface reaction and casting method of aluminum-lithium alloy casting

A technology of aluminum-lithium alloy and interfacial reaction, which is applied in the field of casting aluminum-lithium alloy, can solve the problems of not being disclosed, and achieve the effects of improving quality, reducing pore defects, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

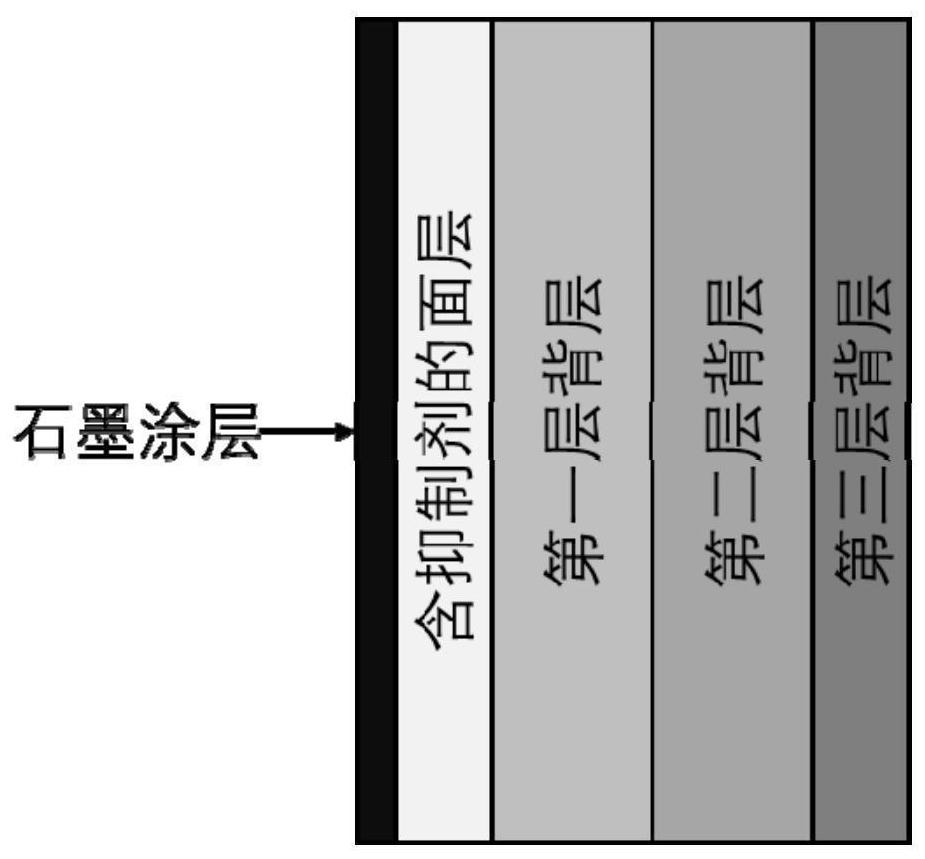

[0038] The preparation of the surface coating includes the following steps: first add the inhibitor to the refractory powder and stir evenly, then add the uniformly mixed refractory powder and inhibitor to the binder in batches, and apply mechanical stirring while adding the powder After all the powder is added to the binder, add a wetting agent and a suspending agent, continue stirring for 0.5h to 2h, and finally add a defoamer to obtain the surface coating. Among them, by adjusting the ratio of refractory powder and binder, the viscosity of the slurry can reach 30-40.

[0039] Sprinkle refractory powder immediately after coating the top coat. The corresponding refractory powder is any one of 80-120 mesh bauxite, zircon powder, forsterite, yttrium oxide and yttrium-stabilized zirconia.

[0040] Sprinkle the refractory material and carry out drying treatment. The drying method is drying in an oven. The drying temperature is 30°C-70°C, the humidity is 40%-60%, and the drying ti...

Embodiment 1

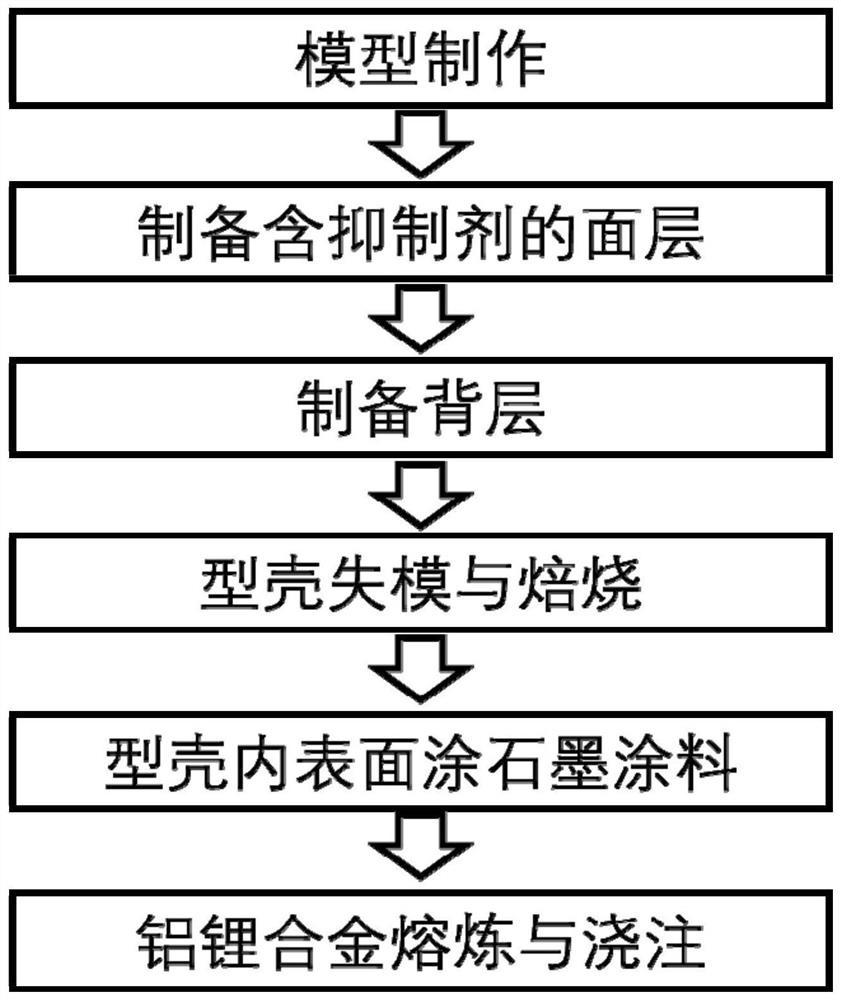

[0056] see figure 1 , Embodiment 1 of the present invention provides a casting method of an aluminum-lithium alloy casting that uses a shell to suppress the interface reaction of the shell-cast aluminum-lithium alloy, the method comprising the following steps:

[0057] (a) Preparation model

[0058] Specifically, it includes the following steps: first, use 3D software to design the 3D shape of the aluminum-lithium alloy casting to be manufactured, process the EPS foam by machine tool processing, and obtain the required foam model, and the foam model is dipped in liquid paraffin to achieve surface smoothing deal with.

[0059] (b) prepare inhibitor-containing surface layer, specifically comprising the following steps:

[0060] 1) Mix 200-mesh LiCl and LiF evenly at a mass ratio of 3:1, and add them to 200-mesh bauxite powder. The weight of LiCl+LiF is 3wt.% of the bauxite powder. After mixing evenly, add it in batches to the alkaline silica sol with a solid content of 30%, m...

Embodiment 2

[0087] (a) Preparation model

[0088] It specifically includes the following steps: first, use three-dimensional software to design the three-dimensional appearance of the aluminum-lithium alloy casting to be manufactured and the mold of the paraffin model, pour liquid paraffin into the mold, take it out after cooling, and obtain the paraffin model of the aluminum-lithium alloy casting to be manufactured.

[0089] (b) prepare inhibitor-containing surface layer, specifically comprising the following steps:

[0090] 1) Mix 200-mesh KCl and LiF evenly at a mass ratio of 2:1, and add them to 200-mesh zircon powder. The weight of KCl+LiF is 3wt.% of the zircon powder. After mixing evenly, add it in batches to the zirconium sol with a solid content of 30%, mechanically stir while adding the powder, and the powder-to-liquid ratio is 3.5.

[0091] 2) After the powder is completely added to the zirconium sol, add fatty alcohol polyoxyethylene ether (JFC) as a wetting agent and hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com