Optical induction device with anti-static elements

An induction device and antistatic technology, applied in the field of optical induction devices, can solve problems such as the influence of the sensing accuracy of the optical induction device, and achieve the effect of eliminating adverse effects and improving the induction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Since the optical sensing device provided by the present invention can be widely used to sense the displacement or inclination of various objects to be sensed, especially for sensing the inclination of the object to be sensed, and the related combination implementations are too numerous to enumerate, so here No need to go into details one by one, but only two preferred embodiments are listed for specific description.

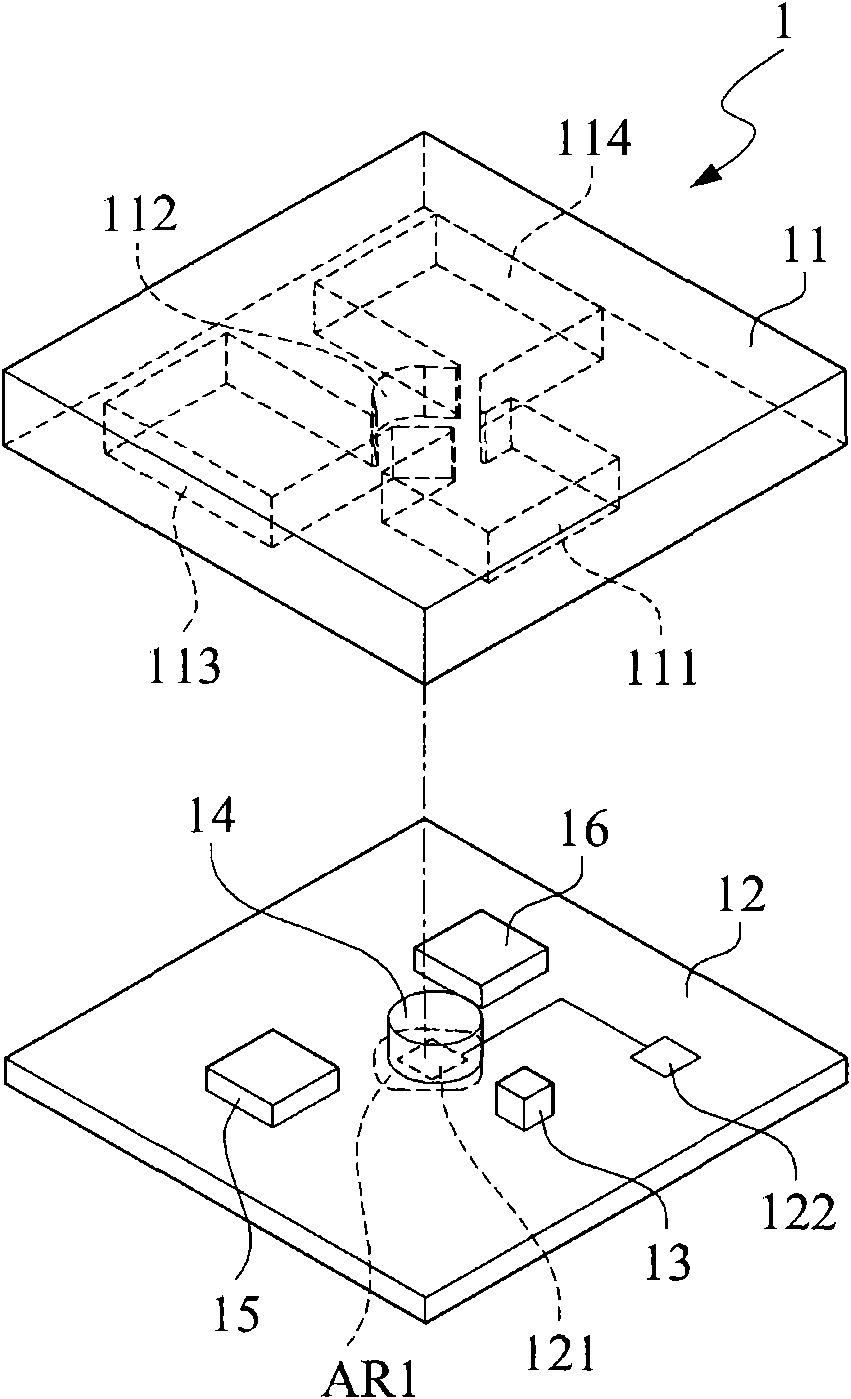

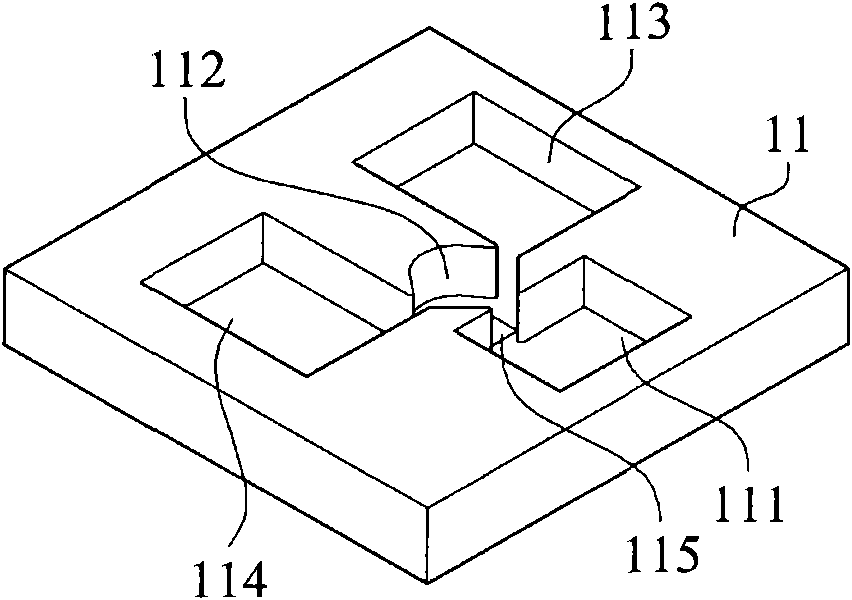

[0044] see Figure 1 to Figure 4 , figure 1 It is a perspective view showing the appearance of the optical sensing device in the first embodiment of the present invention; figure 2 for display when figure 1 The three-dimensional perspective schematic diagram of the middle shell separated from the circuit board; image 3 It is a schematic diagram showing the casing of the first embodiment of the present invention; Figure 4 It is a schematic diagram showing the working principle of the first embodiment of the present invention.

[0045] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com