Acrylate-based polydiacetylene thermochromic material, and preparation method and application thereof

A thermochromic material, acrylate-based technology, applied in the direction of additive processing, etc., can solve the problems of secondary pollution, adverse effects on material performance, etc., achieve the effect of convenient storage, elimination of adverse effects, and expansion of application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing an acrylate-based polydiacetylene thermochromic material, the preparation method comprising:

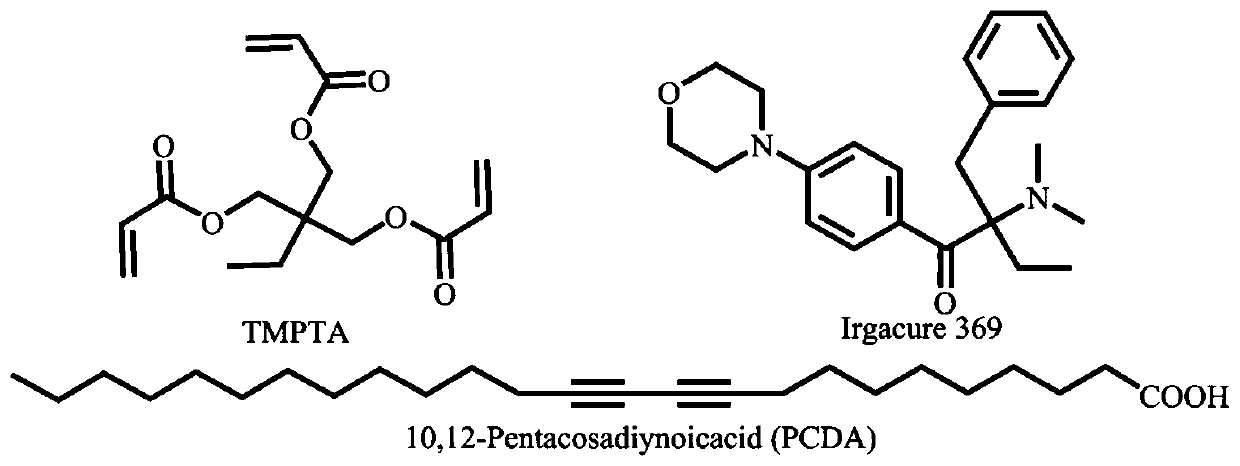

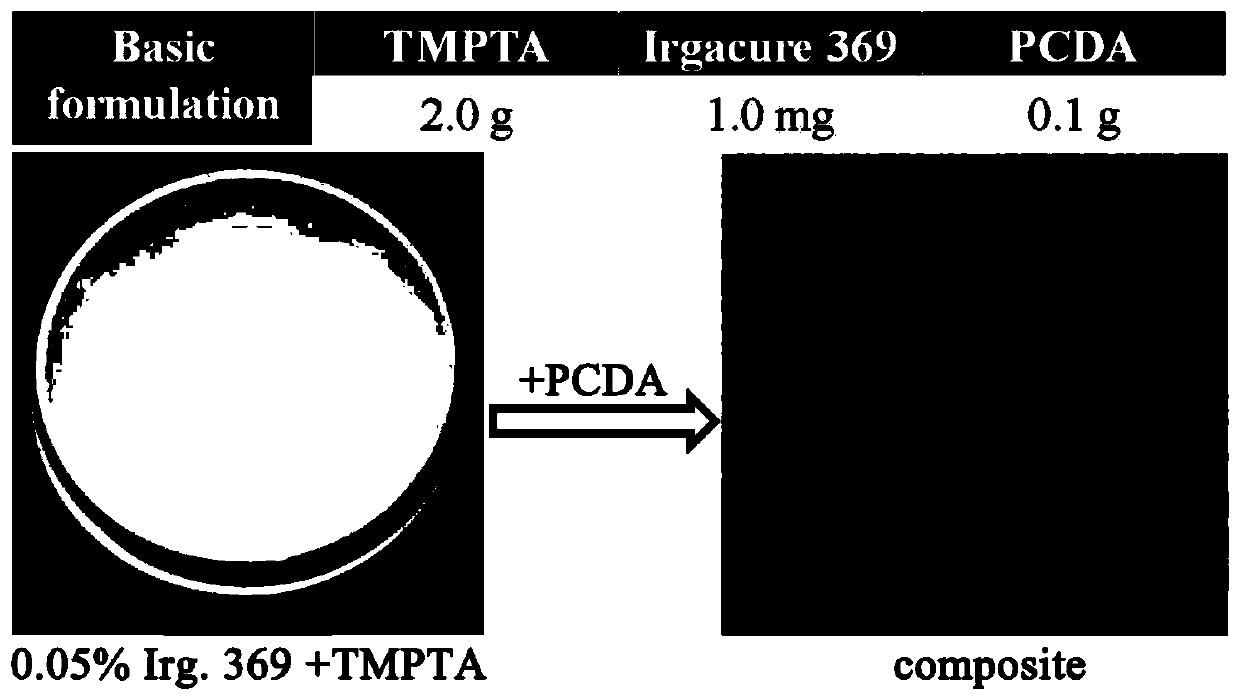

[0020] (1) In a light-proof environment, the photoinitiator Irgacure 369, trimethylolpropane triacrylate and 10,12-pentacosadiynoic acid are mixed to obtain an emulsion;

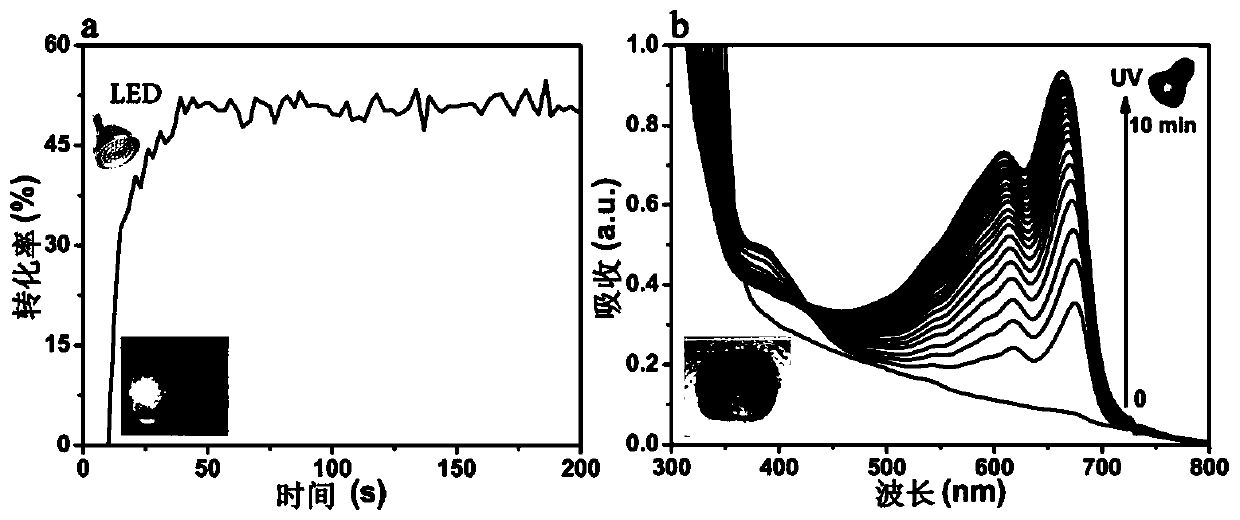

[0021] (2) sequentially irradiating the emulsion with LED light and ultraviolet light to obtain an acrylate-based polydiacetylene thermochromic material.

[0022] In a preferred embodiment of the present invention, in order to improve material performance and response sensitivity, photoinitiator Irgacure 369 and trimethylolpropane triacrylate are mixed for the first time to obtain a colorless liquid. In the light environment, 10,12-pentacosadiynoic acid was added, and an emulsion was obtained after the second mixing.

[0023] In a preferred embodiment of the present invention, in order to improve material performance and response sensitivity, relative to 2g of t...

Embodiment 1

[0036] First mix the photoinitiator Irgacure 369 and trimethylolpropane triacrylate (using mechanical stirring, the stirring time is 3min) to obtain a colorless liquid, then add 10,12- Pentacosadiynoic acid, mixed for the second time (including ultrasonic dispersion for 5 minutes, followed by mechanical stirring for 5 minutes.) to obtain emulsion; sequentially use 405nm LED light (irradiation 2min, light intensity is 110mW / cm 2 ) and 254nm ultraviolet light irradiation (irradiation 5min, light intensity is 15W / cm 2 ) above-mentioned emulsion, obtains acrylate-based polydiacetylene thermochromic material; Relative to the trimethylolpropane trimethacrylate of 2g, the consumption of photoinitiator Irgacure 369 is 1mg, 10,12-pentacoke The dosage of diynoic acid is 0.1 g. The structure diagram of raw material photoinitiator Irgacure 369, trimethylolpropane triacrylate (TMPTA) and 10,12-pentacosadiynoic acid (PCDA) is as follows figure 1 As shown, the three arms of TMPTA contain a...

Embodiment 2

[0038] First mix the photoinitiator Irgacure 369 and trimethylolpropane triacrylate (using mechanical stirring, the stirring time is 2min) to obtain a colorless liquid, then add 10,12- Pentacosadiynoic acid, mixed for the second time (including ultrasonic dispersion for 4min, followed by mechanical stirring for 4min.) to obtain emulsion; sequentially use 405nmLED light (irradiation 1.5min, light intensity is 105mW / cm 2 ) and 254nm ultraviolet light irradiation (irradiation 4min, light intensity is 10W / cm 2 ) above-mentioned emulsion, obtains acrylate-based polydiacetylene thermochromic material; Relative to the trimethylolpropane trimethacrylate of 2g, the consumption of photoinitiator Irgacure 369 is 2mg, 10,12-pentacactyl The dosage of diynoic acid is 0.2 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com