Coarse and fine separation-gravity concentration-magnetic separation combined beneficiation process for processing Anshan type iron ores

An iron ore, coarse subdivision technology, applied in the field of mineral processing, can solve the problems of high reagent cost, environmental pressure, ore property fluctuations, etc., to reduce the cost of flotation reagents, increase the time of ball mills, and the content of fine particles Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

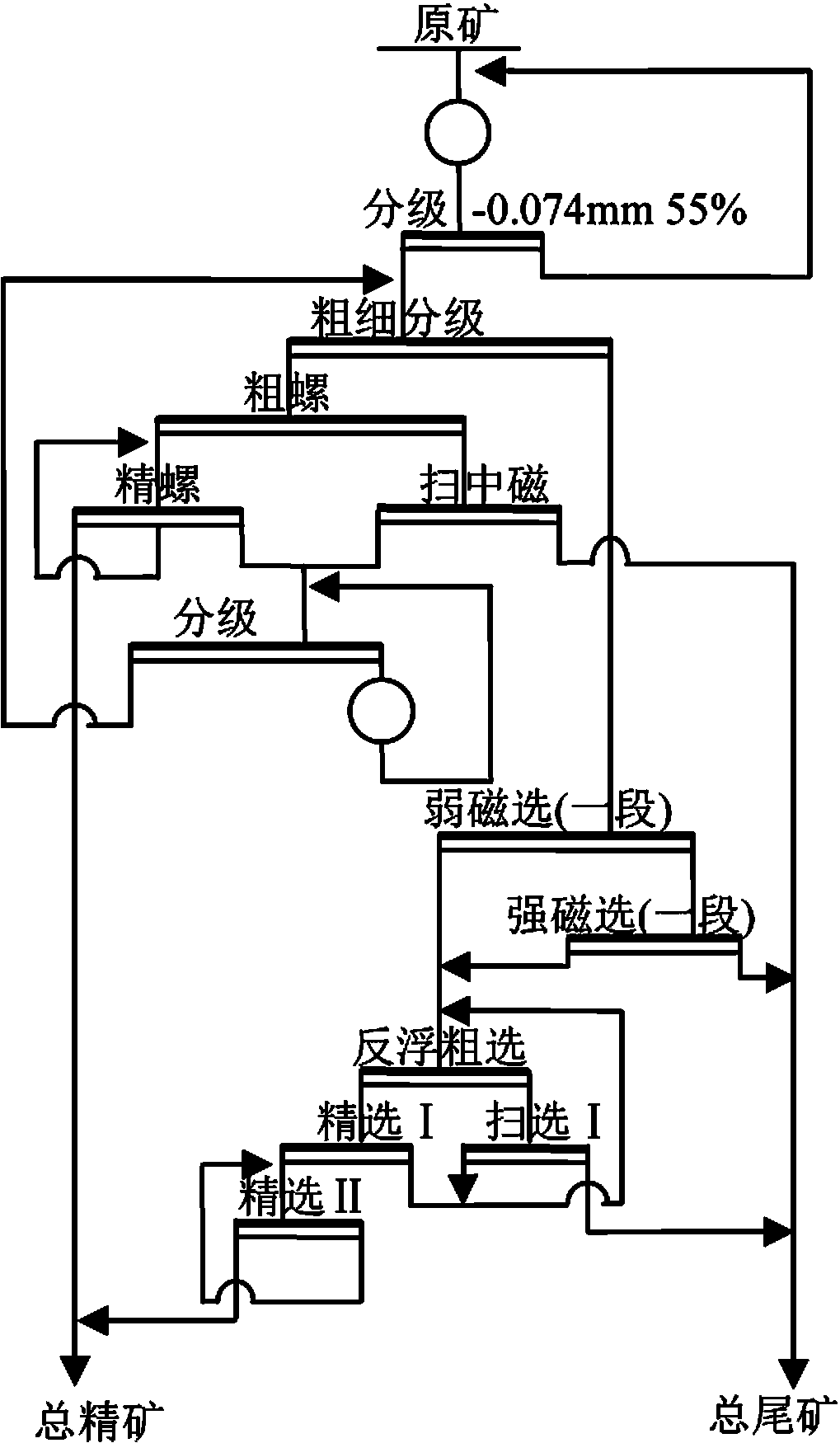

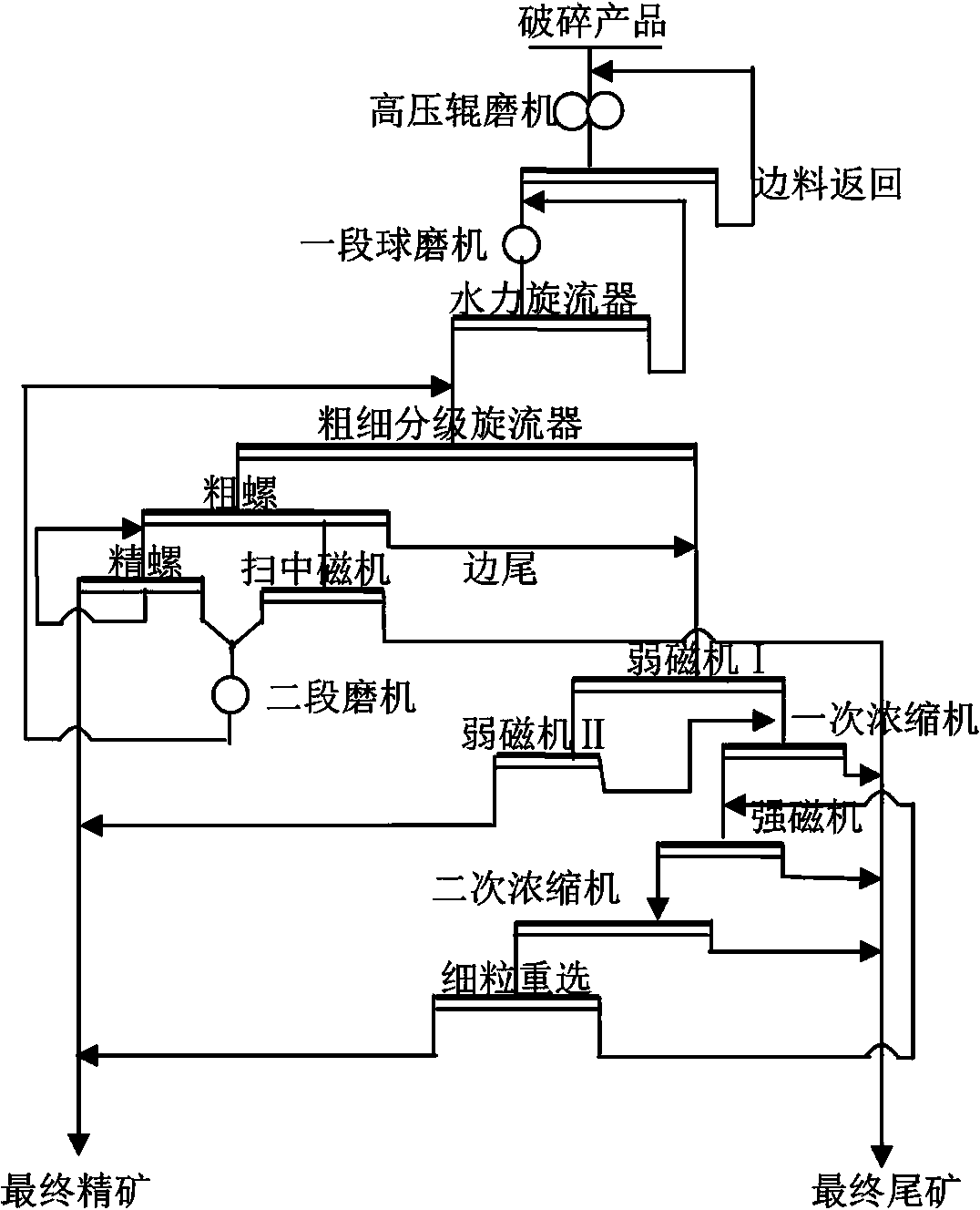

[0034] Such as figure 1 As shown, a kind of coarse-fine separation-heavy-magnetic combined mineral processing process for Anshan-type iron ore of the present invention includes fine crushing, one-stage closed-circuit grinding, coarse and fine classification, gravity separation and magnetic separation, and is characterized in that: comprising the following steps :

[0035] 1) Feed the crushed product with a grade of 29.57% and a particle size of -30mm into the high-pressure roller mill, and the side material with a yield rate of 28% on both sides of the roller surface of the high-pressure roller mill is returned to the high-pressure roller mill for crushing to form a high-pressure roller mill Closed-circuit crushing, the qualified product crushed by the high-pressure roller mill below -5mm is sent to a stage of closed-circuit grinding consisting of a ball mill and a cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com