Method adopting microwave to assist grinding separation of paigeite

A microwave-assisted, boronite technology, applied in the field of mineral processing, can solve the problems of large investment in the grinding process, low energy utilization rate, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of boronite contains B by weight percentage 2 o 3 6%, Fe 2 o 3 28%, MgO 37%, SiO 2 28%, Al 2 o 3 2%, CaO 0.7%, MnO 0.1%, the rest is impurities, iron grade TFe24%, particle size 15~25mm;

[0026] Carry out boronite microwave roasting in a microwave oven, the microwave power applied per 100g boronite is 1500W, and boronite is heated to 500°C;

[0027] Use a ball mill to grind the boronite after microwave roasting, the ball mill speed is 96±2 r / min, and the time is 5min;

[0028] The material after ball milling is sieved to get the part with a particle size of ≤75μm; it accounts for 47.08% of the total weight of all boronite;

[0029] The boronite fine powder is separated by magnetic separation, the magnetic field strength during magnetic separation is 170KA / m, the excitation current is 2A, and the obtained iron concentrate grade TFe is 45.20%;

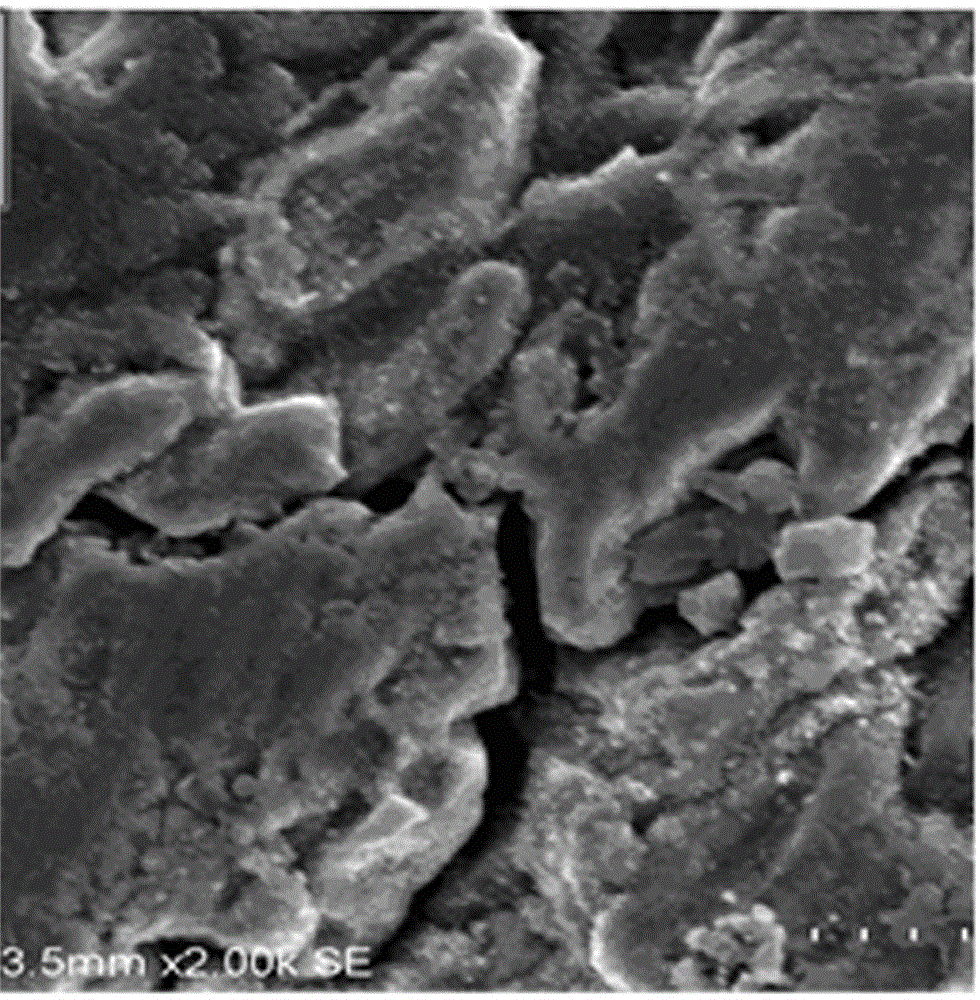

[0030] Boronite and roasted boronite are as follows: figure 1 and 2 As shown, the microscopic mor...

Embodiment 2

[0032] The composition of boronite contains B by weight percentage 2 o 3 7%, Fe 2 o 3 29%, MgO 38%, SiO 2 29%, Al 2 o 3 3%, CaO 0.8%, MnO 0.2%, the rest is impurities, iron grade TFe25%, particle size 15~25mm.

[0033] Carry out the microwave roasting of boronite in the microwave oven, the microwave power applied by 100g boronite is 1800W, and the boronite is heated to 500°C;

[0034] Use a ball mill to grind the boronite after microwave roasting, the ball mill speed is 96±2 r / min, and the time is 6 minutes;

[0035] The material after ball milling is sieved to get the part with a particle size of ≤75μm; it accounts for 47.32% of the total weight of all boronite;

[0036] The boronite fine powder is separated by magnetic separation, the magnetic field strength during magnetic separation is 170KA / m, the excitation current is 2A, and the obtained iron concentrate grade TFe is 46.56%.

Embodiment 3

[0038] The composition of boronite contains B by weight percentage 2 o 3 6.2%, Fe 2 o 3 28.6%, MgO 37.7%, SiO 2 28.3%, Al 2 o 3 2.5%, CaO 0.7%, MnO 0.2%, the rest is impurities, iron grade TFe24.5%, particle size 15~25mm;

[0039] Carry out the microwave roasting of boronite in the microwave oven, the microwave power applied by 100g boronite is 2000W, and the boronite is heated to 500°C;

[0040] Use a ball mill to grind the boronite after microwave roasting, the ball mill speed is 96±2 r / min, and the time is 5min;

[0041] The material after ball milling is sieved to get the part with a particle size of ≤75μm; it accounts for 51.02% of the total weight of all boronite;

[0042] The boronite fine powder is separated by magnetic separation, the magnetic field strength during magnetic separation is 170KA / m, the excitation current is 2A, and the obtained iron concentrate grade TFe is 52.67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com