Method for pretreating eucalyptus graded lignin and co-producing furfural based on DES two-phase system

A two-phase system, lignin technology, applied in the direction of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of single type of lignin, long separation time, insufficient utilization of lignocellulose components, etc. Achieve the effects of easy control of reaction, short processing time, designable structure and recyclable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

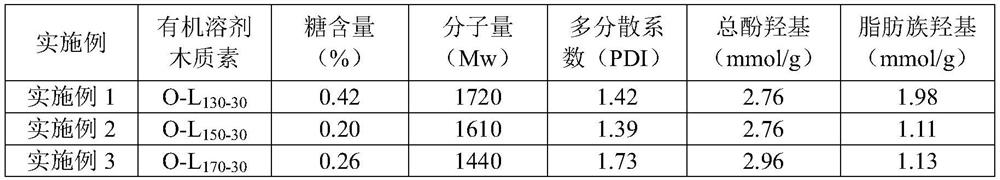

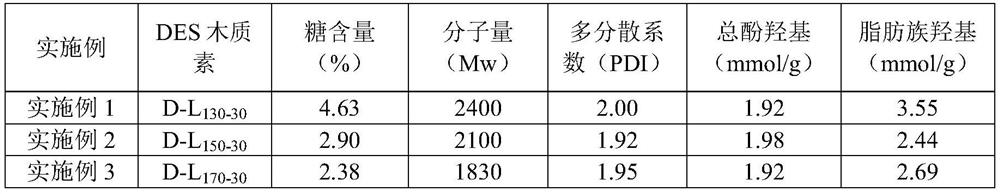

Embodiment 1

[0038](1) Grind Eucalyptus gigantea to 20-100 meshes, extract and dry with benzene alcohol, weigh 3 g of raw materials and DES choline chloride / lactic acid, organic solvent 2-MTHF according to the ratio of 1:5:10 (g :g:mL) ratio blended into the reactor, adding 0.2mol / L of aluminum sulfate and 0.075mol / L of sulfuric acid as a catalyst, rapid heating to 130 ℃ for 30min after the end of the reaction, to obtain a mixed system;

[0039] (2) The mixed system obtained in step (1) is separated to obtain the eutectic reaction mixture and the organic extract phase, and the organic extract phase is filtered through a disposable syringe filter with a pore size of 0.2 μm, and then detected and analyzed by a high performance liquid chromatograph Calculate the furfural content; the eutectic reaction mixture is washed with acetone / water solution (1 / 1, v / v) and centrifuged several times to obtain an eluent containing DES lignin;

[0040] (3) After the organic extract phase and eluent that ste...

Embodiment 2

[0047] (1) Grind Eucalyptus gigantea to 20-100 meshes, extract and dry with benzene alcohol, weigh 3 g of raw materials and DES choline chloride / lactic acid, organic solvent 2-MTHF according to the ratio of 1:5:10 (g :g:mL) was blended into the reactor, adding 0.2mol / L aluminum sulfate and 0.075mol / L sulfuric acid as catalysts, rapidly heating up to 150°C for 30min and then ending the reaction to obtain a mixed system;

[0048] (2) The mixed system obtained in step (1) is separated to obtain the eutectic reaction mixture and the organic extract phase. After the organic extract phase is filtered through a disposable syringe filter with a pore size of 0.2 μm, it is detected by high performance liquid chromatography and Calculate the furfural content; the eutectic reaction mixture is washed with acetone / water (1 / 1, v / v) and centrifuged several times to obtain an eluent containing DES lignin;

[0049] (3) After the organic extract phase and eluent that step (2) obtains are rotary-...

Embodiment 3

[0052] (1) Grind Eucalyptus gigantea to 20-100 meshes, extract and dry with benzene alcohol, weigh 3 g of raw materials and DES choline chloride / lactic acid, organic solvent 2-MTHF according to the ratio of 1:5:10 (g :g:mL) ratio blended into the reactor, adding 0.2mol / L of aluminum sulfate and 0.075mol / L of sulfuric acid as a catalyst, rapid heating to 170 ℃ for 30min after the end of the reaction, to obtain a mixed system;

[0053] (2) The mixed system obtained in step (1) is separated to obtain the eutectic reaction mixture and the organic extract phase. After the organic extract phase is filtered through a disposable syringe filter with a pore size of 0.2 μm, it is detected by high performance liquid chromatography and Calculate the furfural content; the eutectic reaction mixture is washed with acetone / water (1 / 1, v / v) and centrifuged several times to obtain an eluent containing DES lignin;

[0054] (3) After the organic extract phase and eluent that step (2) obtains are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com