A rotor and a d-type pulper using the same

A pulper and rotor technology, applied in recycling technology, raw material separation, paper recycling, etc., can solve problems that have not been effectively solved, and achieve the effects of prolonging the life of the rotor, reducing dissociation and refinement, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

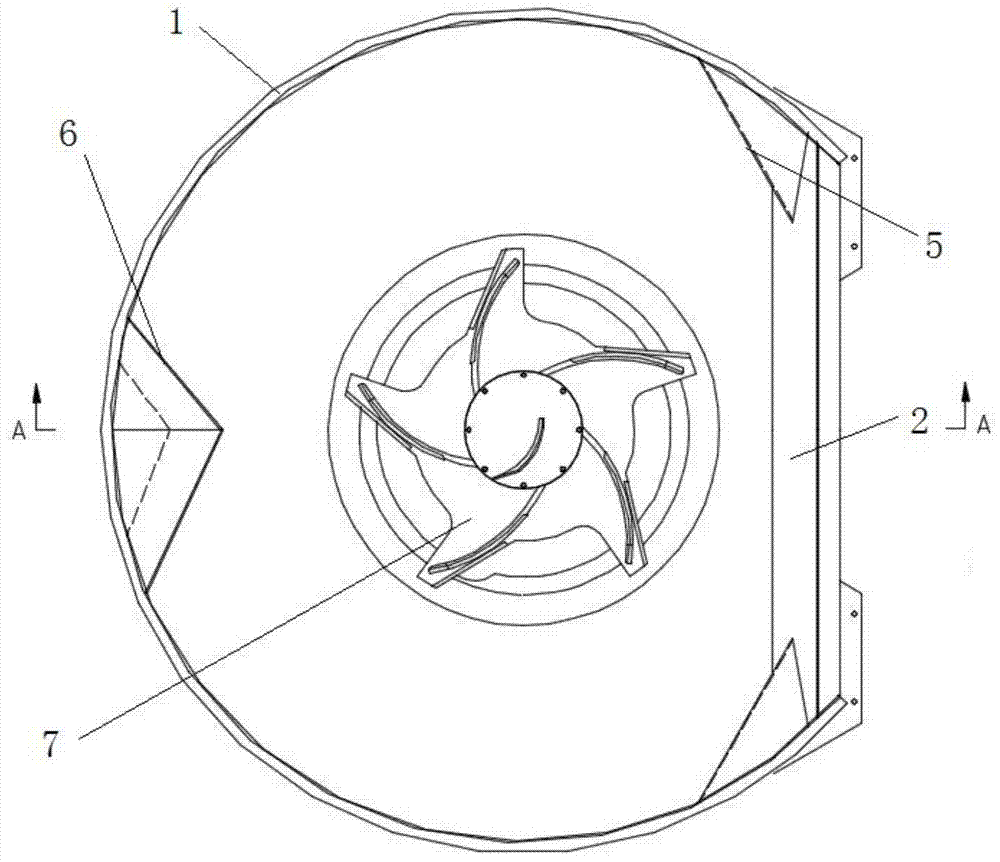

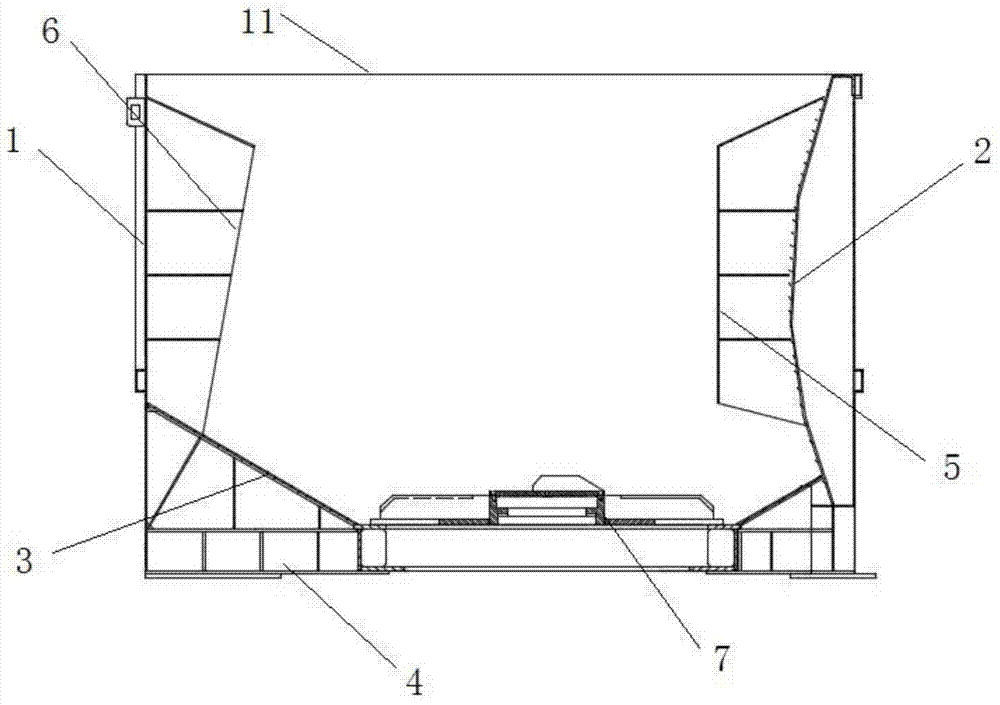

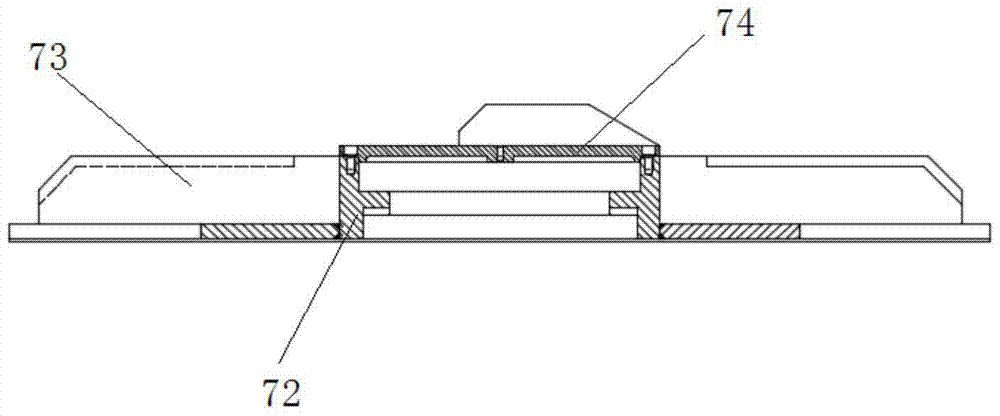

[0043] According to the solution of the embodiment of the present invention, a rotor is used for waste paper pulping treatment in the waste paper pulping section of the papermaking industry, so as to dissociate and separate the waste paper raw materials to separate useful fibers and impurities, and has a rotor bottom plate 71 and a rotor central shaft 72 , the rotor bottom plate 71 and the rotor central shaft 72 are circular, and the rotor central shaft 72 is fixedly arranged at the center of the rotor bottom plate 71, and the rotor bottom plate 71 and the rotor central shaft 72 can rotate synchronously. A plurality of blades 711 protruding outward are provided, and the direction in which the blades 711 extend outward deviates from the axis of the rotor bottom plate 71 and the rotor central shaft 72 , and each blade 711 extends in the same direction.

[0044] According to the solution of the embodiment of the present invention, a number of pulping blades 73 for guiding and diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com