Method for reinforcing copper inhibition molybdenum extraction during copper-molybdenum separation

A copper-molybdenum and copper inhibitor technology, which is applied in the separation of copper and molybdenum, strengthens copper suppression and extraction of molybdenum, and can solve problems such as difficult control of process indicators, large fluctuations in recovery rate and product quality, and difficulty in inhibiting secondary copper minerals. The effect of eliminating passivation, improving grade and recovery rate, and avoiding muddy phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

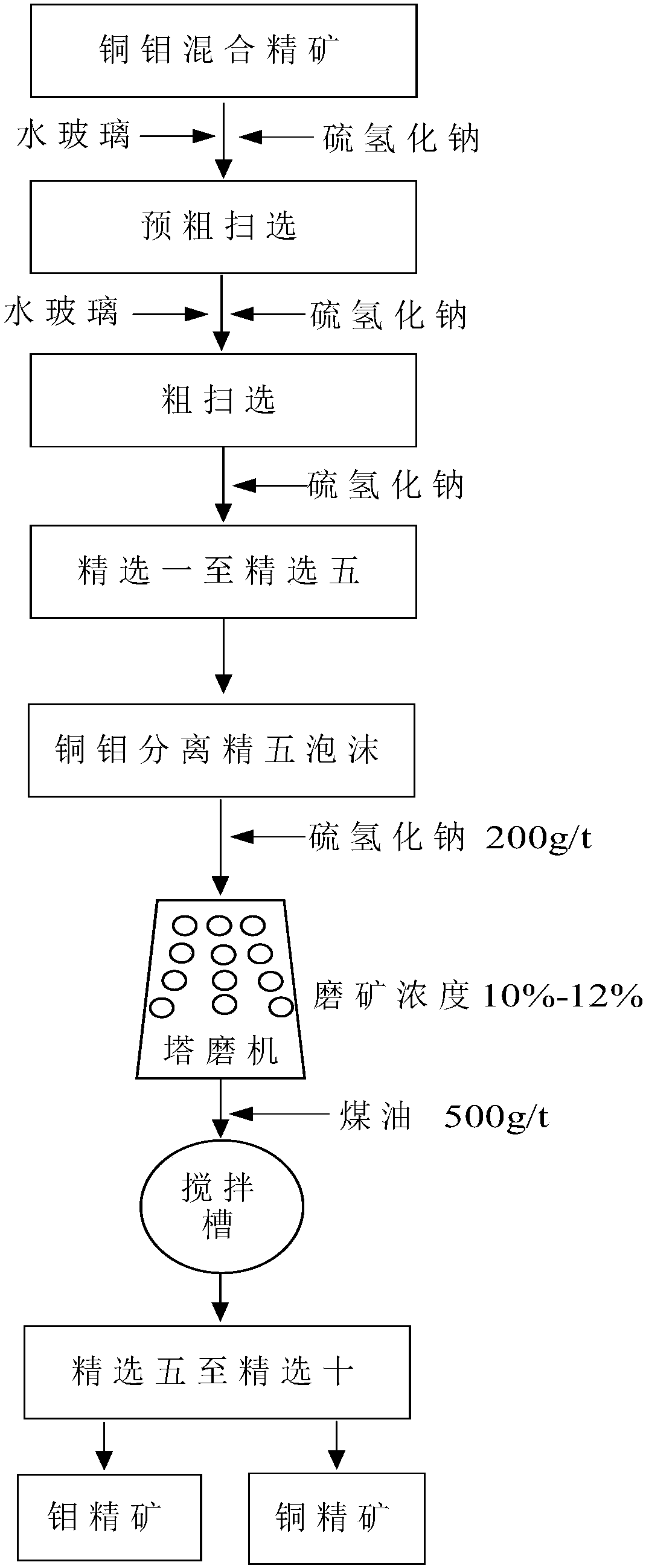

[0023] Include the following steps:

[0024] a. Copper-molybdenum mixed concentrate is pre-cast after rough sweeping. The pre-tailing includes one pre-rougher and three pre-sweeps. After one rougher, three sweeps and five beneficiations, the concentrate foam is obtained;

[0025] b. adding copper inhibitor sodium hydrosulfide to the concentrate foam obtained in step a, the consumption is 180g / t mixed concentrate;

[0026] c. The ore pulp formed in step b enters the mill for regrinding; the mill is a tower mill, and the grinding concentration is 10%;

[0027] d. adding a molybdenum collector to the grinding product obtained in step c, the molybdenum collector is non-polar hydrocarbon oil, and the consumption is 480g / t mixed concentrate;

[0028] e. The product obtained in step d enters the flotation operation of refining 6 to 10 to obtain the final copper concentrate and molybdenum concentrate.

Embodiment 2

[0030] Include the following steps:

[0031] a. Copper-molybdenum mixed concentrate is pre-cast after rough sweeping. The pre-tailing includes one pre-rougher and three pre-sweeps. After one rougher, three sweeps and five beneficiations, the concentrate foam is obtained;

[0032] b. adding copper inhibitor sodium hydrosulfide to the concentrate foam obtained in step a, the consumption is 200g / t mixed concentrate;

[0033] c. The ore pulp formed in step b enters a mill for regrinding; the mill is a tower mill with a grinding concentration of 11%.

[0034] d. adding a molybdenum collector to the grinding product obtained in step c, the molybdenum collector is non-polar hydrocarbon oil, and the consumption is 500g / t mixed concentrate;

[0035] e. The product obtained in step d enters the flotation operation of refining 6 to 10 to obtain the final copper concentrate and molybdenum concentrate.

Embodiment 3

[0037] Include the following steps:

[0038] a. Copper-molybdenum mixed concentrate is pre-cast after rough sweeping. The pre-tailing includes one pre-rougher and three pre-sweeps. After one rougher, three sweeps and five beneficiations, the concentrate foam is obtained;

[0039] b. adding copper inhibitor sodium hydrosulfide to the concentrate foam obtained in step a, the consumption is 220g / t mixed concentrate;

[0040] c. The ore pulp formed in step b enters a mill for regrinding; the mill is a tower mill with a grinding concentration of 12%.

[0041] d. adding molybdenum collector to the grinding product obtained in step c, the molybdenum collector is non-polar hydrocarbon oil, and the consumption is 520g / t mixed concentrate;

[0042] e. The product obtained in step d enters the flotation operation of refining 6 to 10 to obtain the final copper concentrate and molybdenum concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com