A kind of floating nano zero-valent iron material and preparation method thereof

A nano-zero-valent iron and biomass material technology, applied in the field of nano-materials, can solve the problems of high energy consumption, influence of nano-material loading and reactivity performance, inability to suspend or float naturally, etc., to achieve easy recovery and avoid agglomeration The effect of growing up and inactivating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

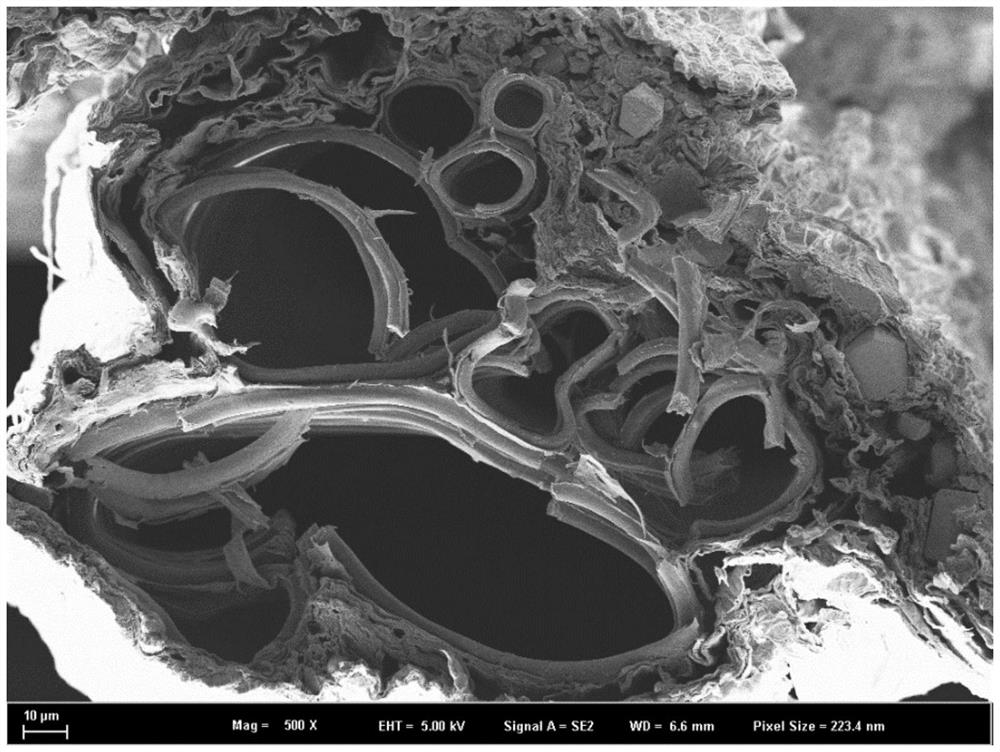

[0039]Weigh the garlic waste, crush and sieve through 40 mesh, throw it into the water and stir, soak for 24 hours; collect the garlic waste particles floating on the water surface, add sodium hydroxide solution to adjust its pH value at 13, keep stirring After 12 hours, the particles floating on the water surface were collected; 10 liters of ferric chloride ion solution of 0.1M concentration was prepared, and 1000 grams of floatable garlic slag adsorbents (measured on a dry basis) were dropped into, and after stirring and reacting for 300 minutes, the After the adsorbent is filtered and washed 3 times with distilled water; the obtained adsorbent is put into a reaction kettle, and a sodium borohydride solution with a concentration of 0.1M is added until there are no more bubbles, and the stirring reaction is continued for 5 minutes. The loaded nano-zero-valent iron composite material is washed repeatedly with clean water for 2-3 times, then put into a plastic film bag, vacuumiz...

Embodiment 2

[0041] Weigh the garlic waste, crush and sieve through 80 mesh, throw it into water and stir, soak for 36 hours; collect the garlic waste particles floating on the water surface, add potassium hydroxide solution to adjust its pH value at 12.5, and keep stirring After 24 hours, the particles floating on the water surface were collected; 20 liters of ferric chloride ion solution of 0.2M concentration was prepared, and 500 grams of floatable garlic slag adsorbents (measured on a dry basis) were dropped into, and after stirring and reacting for 300 minutes, the After the adsorbent is filtered and washed 3 times with distilled water; the obtained adsorbent is put into a reaction kettle, and a sodium borohydride solution with a concentration of 0.2M is added until no more bubbles are generated, and the stirring reaction is continued for 5 minutes, and the above adsorbent is separated by filtration. The loaded nano-zero-valent iron composite material is repeatedly washed with clean wa...

Embodiment 3

[0043] Weigh mangosteen residue waste, crush and sieve through 80 meshes, throw into an alkaline aqueous solution with a pH value of 12.5, stir and soak for 36 hours; collect the particles suspended in the liquid surface or even 5 cm below the liquid surface; prepare 20 liters of ferric chloride ion solution of 0.15M concentration, drop into 2000 grams (dry basis measurement) of the mangosteen slag adsorbent collected above, after stirring and reacting for 180 minutes, adsorbent is filtered, after washing 3 times with distilled water; Gained adsorbent Put it into the reaction kettle, add a sodium borohydride solution with a concentration of 0.05M until no more bubbles appear, continue to stir and react for 5 minutes, filter and separate the above suction-loaded nano-zero-valent iron composite material, and wash it repeatedly with clean water for 2 After -3 times, put it into a plastic film bag, vacuumize it, and seal it in plastic to obtain a floating nanometer zero-valent iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com