High-speed centrifugal pump reverse rotation hydraulic turbine device

A hydraulic turbine, high-speed centrifugal technology, applied to the components of pumping devices for elastic fluids, reaction engines, pumps, etc., can solve the operating conditions without targeted consideration of small flow and high energy. The hydraulic loss in the inlet section of the hydraulic turbine and the difficulty of design and development of the hydraulic turbine are not considered, so as to achieve the effect of improving the efficiency of energy recovery and utilization, improving the efficiency of energy recovery and improving the efficiency of energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

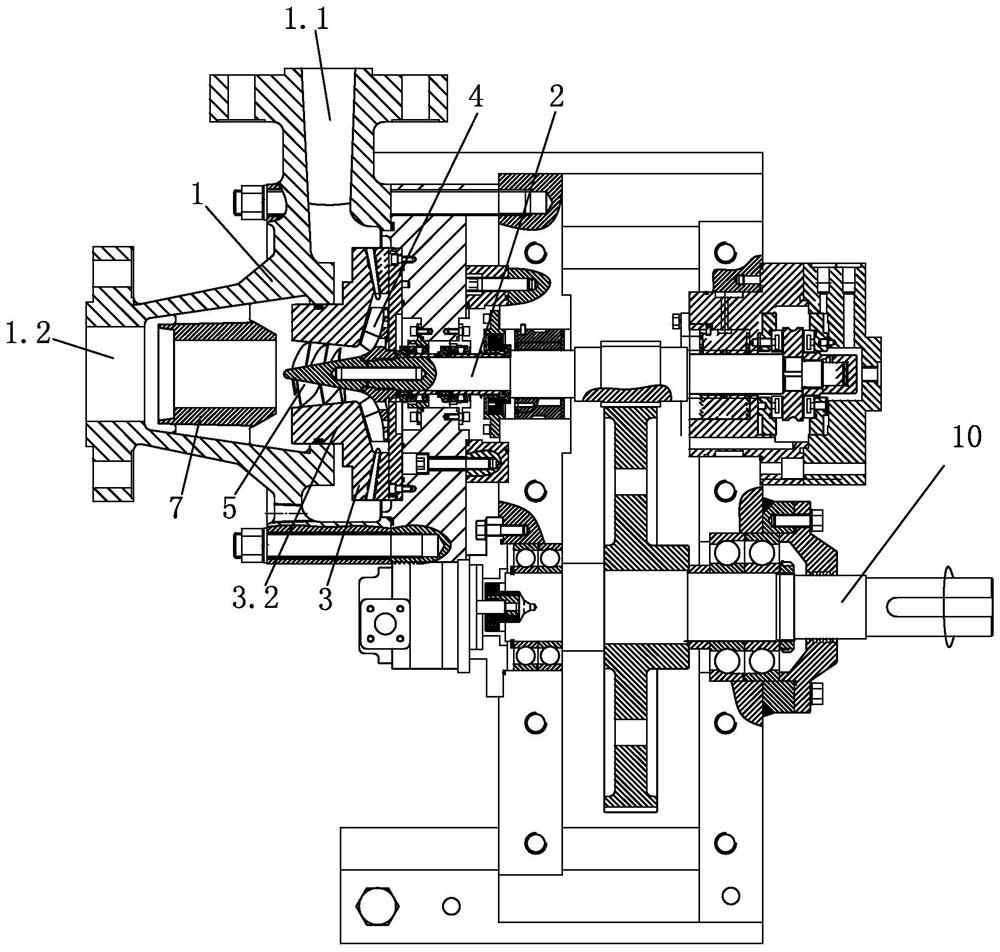

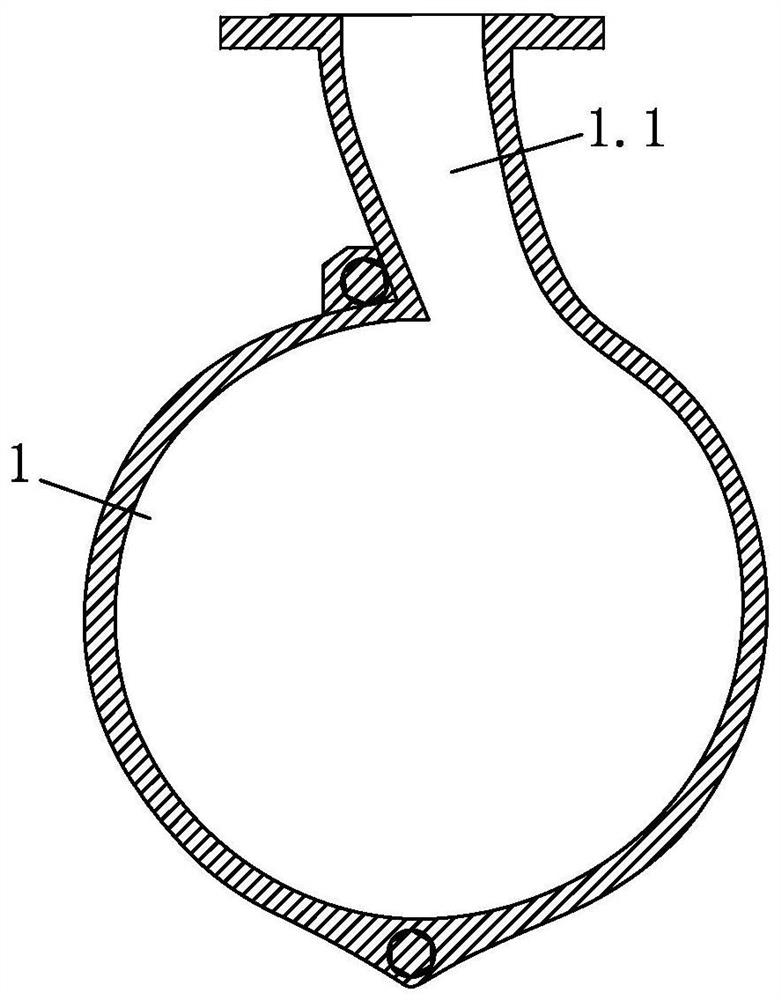

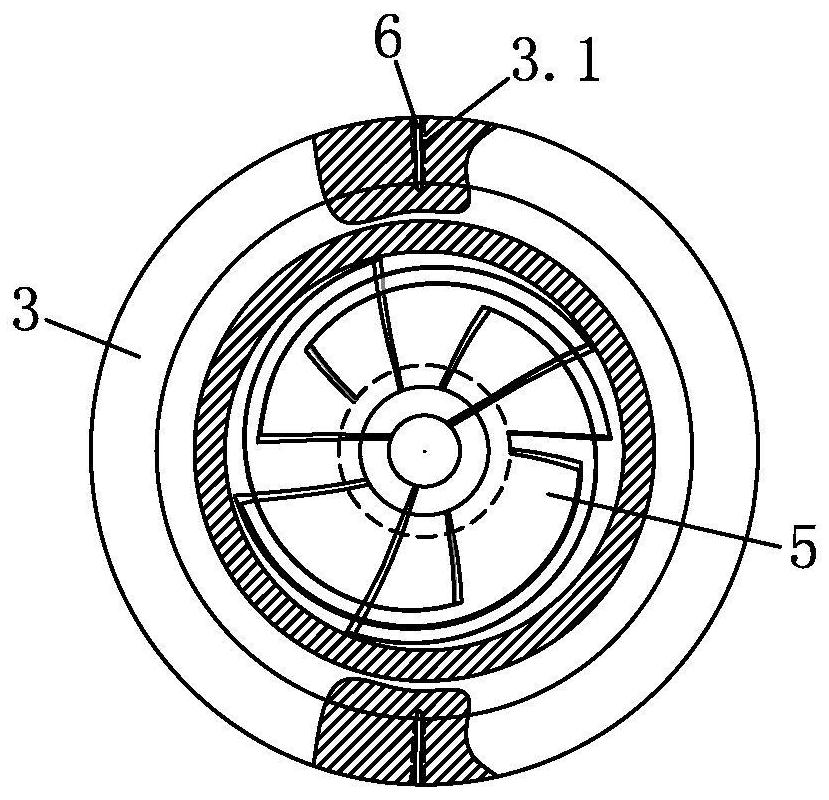

[0023] The traditional centrifugal pump works in reverse as a hydraulic turbine, including a turbine shaft, a volute, and an impeller. The impeller is set in the inner cavity of the volute. The turbine shaft and the impeller are fixed so that they can rotate together with the impeller. The turbine shaft passes through the gear box. The main shaft 10 is then connected to a generator set or load through a coupling. The traditional hydraulic turbine principle is: high-pressure fluid flows into the volute from the inlet section, and its pressure energy is converted into kinetic energy to drive the impeller and turbine shaft to rotate, and finally flows out from the outlet section. The turbine shaft drives the generator set or load to perform external work. , Complete the energy recovery and utilization of high-pressure mobile working fluid.

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the specification, but the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com