A kind of coal tar waste residue extraction and separation method

A separation method, coal tar technology, applied in the direction of tar processing through selective solvent extraction, solid waste removal, etc., can solve the problems of high toxicity of extraction solvent, high boiling range, large recovery energy consumption, etc., to reduce the secondary environment The risk of pollution, the effect of simple process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

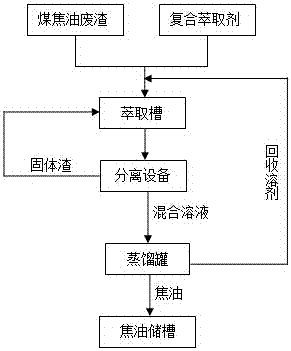

Method used

Image

Examples

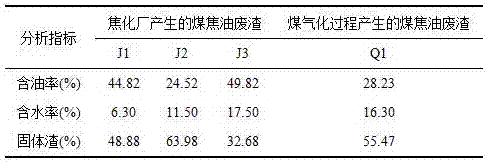

Embodiment 1

[0036] Under normal temperature and pressure, furfural and methyl acetate are formulated into a furfural ester composite extractant according to the volume percentage of 5% and 95%, and then the composite extractant is mixed with the coal tar waste residue J1 produced by the coking plant according to the mass ratio of 1:1 mixed in the extraction tank to obtain the mixture; under the condition of normal temperature and pressure, the above mixture was fully stirred for 0.5h, left standing for 0.5h, and then sent to the separation equipment for separation to obtain the mixed solution and solid residue; The separated mixed solution is placed in a distillation tank, heated to boiling and separated by distillation to obtain a composite extractant and tar, the composite extractant is recycled, and the tar is sent to a tar storage tank; the solid residue obtained by separation is again mixed with a composite extractant or The composite extraction agent recovered in the above steps is s...

Embodiment 2

[0038] Under normal temperature and pressure, furfural and ethyl acetate are formulated into a furfural ester composite extractant according to the volume percentage of 12% and 88%, and then the composite extractant and the coal tar waste residue J2 produced by the coking plant are prepared according to the mass ratio of Mix 2:1 in the extraction tank to obtain the mixture; under the condition of normal temperature and pressure, fully stir the above mixture for 40min, let it stand for 0.5h, and then send it to the separation equipment for separation to obtain the mixed solution and solid slag; the separation The obtained mixed solution is placed in a distillation tank, heated to boiling and separated by distillation to obtain a composite extractant and tar, the composite extractant is recycled, and the tar is sent to a tar storage tank; The composite extraction agent recovered in the step is subjected to secondary washing and separation to obtain a mixed solution and solid resi...

Embodiment 3

[0040]Under normal temperature and pressure, furfural, ethyl acetate and methyl acetate were formulated into furfural ester composite extractant according to the volume percentage of 12%, 58%, and 30%, and then the composite extractant was mixed with the coal gasification process. Coal tar waste residue Q1 is mixed in the extraction tank according to the mass ratio of 2.5:1 to obtain the mixture; under the condition of normal temperature and pressure, the above mixture is fully stirred for 50 minutes, allowed to stand for 1 hour, and then sent to the separation device for separation to obtain the mixture Solution and solid slag; the separated mixed solution is placed in a distillation tank, heated to boiling and separated by distillation to obtain a composite extractant and tar, the composite extractant is recycled, and the tar is sent to a tar storage tank; the solid slag obtained by separation, The composite extractant or the composite extractant recovered in the above steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com