Method for recovering precious metal palladium from aniline tar

A technology for aniline tar and precious metals, applied in the field of resource recycling, can solve problems such as low extraction efficiency and serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

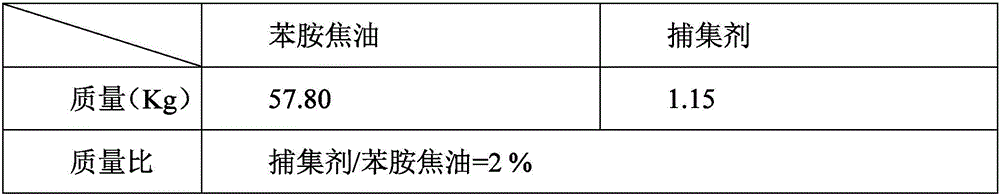

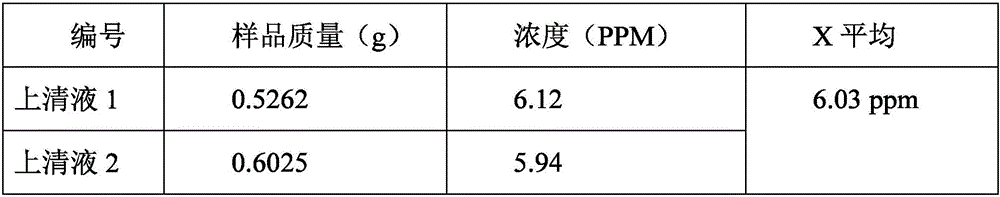

[0051] Example 2: After the aniline tar raw material is pretreated, adjust the pH to 10, add a self-made precious metal collector, the amount of the collector is 2% of the quality of the aniline tar raw material, and then heat it to 160°C at a constant temperature and continue stirring , After reacting for a certain period of time, let it stand and settle, and take the supernatant to measure the palladium content therein. The test result was 4.25ppm, qualified, cooled and filtered, the filter residue was retained, and the filtrate was incinerated; the obtained filter residue was burned in a muffle furnace, the burning temperature was 600°C, and the burning time was 1h. After the burning is complete, collect and retain the ash; add an appropriate amount of mixed acid to the obtained ash, stir with a glass rod, boil at low temperature to dissolve completely, cool and filter, collect and process the filter residue, and retain the filtrate; Nitrate, then replace. After a period o...

Embodiment 3

[0052] Example 3: After the raw material of aniline tar is pretreated, the pH is adjusted to 10, and a self-made precious metal collector is added. The amount of the collector is 2% of the quality of the raw material of aniline tar, and then heated to 200°C at a constant temperature, and continuously stirred , After reacting for a certain period of time, let it stand and settle, and take the supernatant to measure the palladium content therein. The test result was 4.02ppm, qualified, cooled and filtered, the filter residue was retained, and the filtrate was incinerated; the obtained filter residue was burned in a muffle furnace, the burning temperature was 600°C, and the burning time was 1h. After the burning is complete, collect and retain the ash; add an appropriate amount of mixed acid to the obtained ash, stir with a glass rod, boil at low temperature to dissolve completely, cool and filter, collect and process the filter residue, and retain the filtrate; Nitrate, then rep...

Embodiment 4

[0053] Example 4: After the aniline tar raw material is pretreated, adjust the pH to 10, add a self-made precious metal collector, the amount of the collector is 2% of the quality of the aniline tar raw material, and then heat it to 200°C at a constant temperature, and continue to stir , After reacting for a certain period of time, let it stand and settle, and take the supernatant to measure the palladium content therein. The test result was 4.07ppm, qualified, cooled and filtered, the filter residue was retained, and the filtrate was incinerated; the obtained filter residue was burned in a muffle furnace, the burning temperature was 800°C, and the burning time was 1h. After the burning is complete, collect and retain the ash; add an appropriate amount of mixed acid to the obtained ash, stir with a glass rod, boil at low temperature to dissolve completely, cool and filter, collect and process the filter residue, and retain the filtrate; Nitrate, then replace. After a period o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com