Fermentation treatment technology for living microorganism compositions of breeding byproducts

A microbial composition and treatment process technology, applied in waste treatment, enzymatic/microbiological devices, gas production bioreactors, etc., can solve problems such as unrealizable, prolonging the fermentation cycle, affecting microbial reproduction, etc., and achieve simple structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

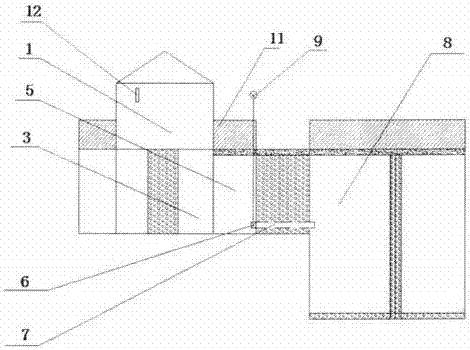

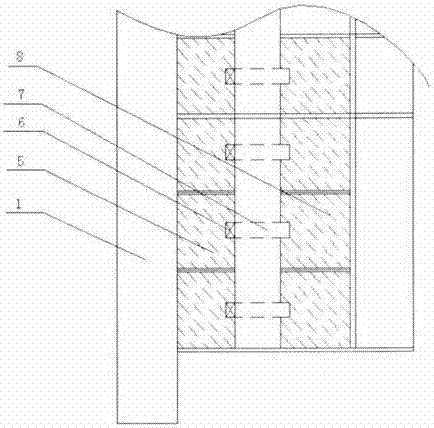

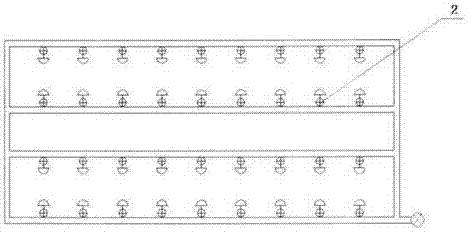

[0020] As shown in Figures 1 to 4, a live microbial composition fermentation treatment process for aquaculture by-products includes a fermentation chamber 1, and a waterproof wall 11 is provided outside the fermentation chamber 1, and the fermentation chamber 1 1 is provided with a sprinkler system 2, and a leachate pool 3 under the grate is set at the bottom of the fermentation chamber body 1, and a water grate 4 is arranged on the leachate pool 3 under the grate, and the leachate pool 3 under the grate is connected with the filter pool 5, and the filtration The pool 5 is connected to the biogas recovery pool 8 through the gate valve 6 and the pipeline 7. The gate valve 6 is also provided with a valve handle 9. There are at least two leachate pools 3 arranged vertically under the grate. The fermentation bin body 1 is also provided with steel bars. Glass windows 12, the number of reinforced glass windows 12 is more than one, the material of the roof of the fermentation bin is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com