Patents

Literature

37results about How to "Productivity is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrialized heat regeneration asphalt mixture and preparation method thereof

The invention discloses a factory hot recycled asphalt mixture, which comprises the following components in weight percentage: 44-92% of new aggregate, 1-3% of mineral powder, 5-50% of old asphalt mixture and 1.7-3.0% new asphalt binder, wherein the weight ratio of fine material with a particle size of 0-15mm to coarse material with a particle size of 15-25mm in the old asphalt mixture is 0.5-2:1. The invention also discloses its preparation method. The industrial heat-regenerated asphalt mixture of the present invention can save a large amount of asphalt and gravel materials without regenerating agent, save engineering investment, turn waste into treasure, and save energy; In terms of water damage performance, it is not inferior to the fresh asphalt mixture; in addition, the preparation method of the invention can effectively reduce the smoke phenomenon caused by the old material when heated, reduce the pollution to the environment, and has a good environmental protection effect.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

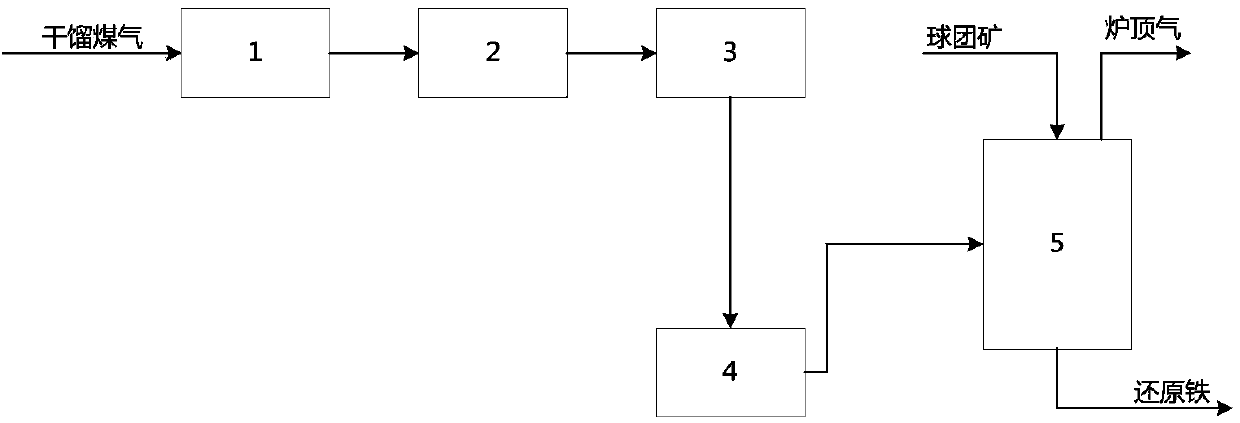

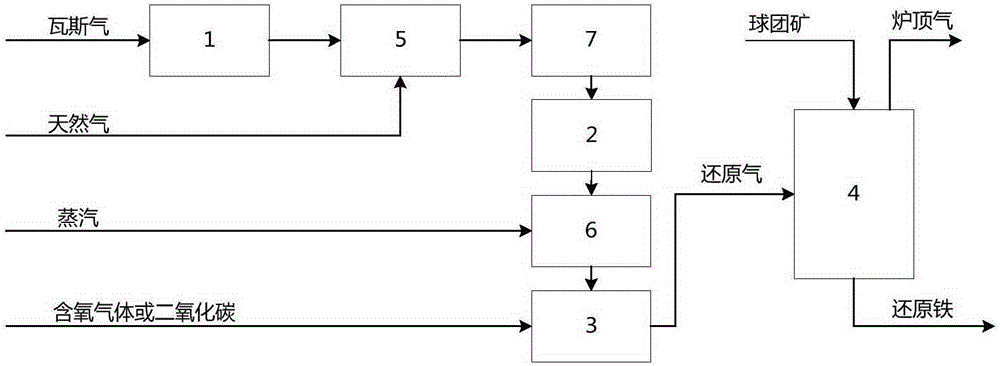

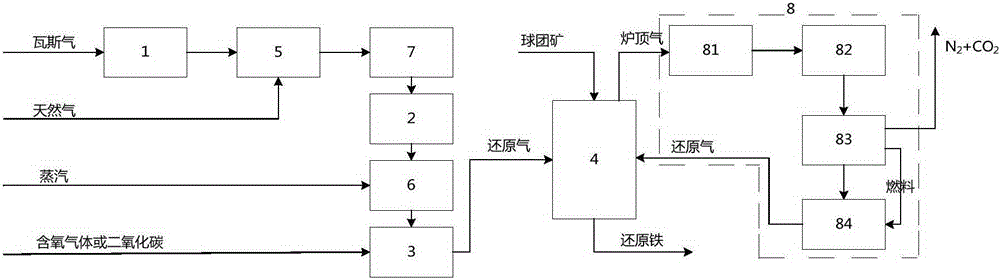

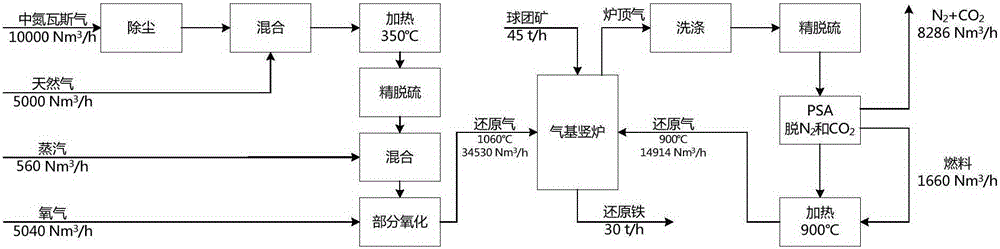

Method and device for producing reduced iron through synthetic gas prepared from high-nitrogen content retort gas

ActiveCN103805728AAvoid lostImprove utilization value and efficiencyCombustible gas catalytic treatmentShaft furnaceBrown iron oxideChemistry

The invention provides a method and device for producing reduced iron through synthetic gas prepared from high-nitrogen content retort gas. The method comprises the steps of purifying and desulfurizing the high-nitrogen content retort gas until the sulfur content thereof is smaller than or equal to 10ppm; heating the desulfurized retort gas to the temperature of 300 DEG C to 650 DEG C as to-be-transformed gas, or adding part of superheated steam into the retort gas according to the constitution of the retort gas as the to-be-transformed gas; leading the to-be-transformed gas into a reforming furnace which contains a catalyst to transform the to-be-transformed gas on the catalyst so as to obtain the synthetic gas containing H2, CO and N2; taking the synthetic gas formed after the transformation as completely or partially-reduced gas, and directly sending the synthetic gas into a gas-based shaft furnace to reduce iron oxide so as to produce the reduced iron. After the N2, CO2 and sulfide are removed, the tail gas at the furnace top can be returned to the shaft furnace to be recycled as reducing gas. The method and the device disclosed by the invention are used for improving the use values and efficiency of the retort gas and realizing an effect and an aim of producing the reduced iron by taking the natural gas as a raw material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

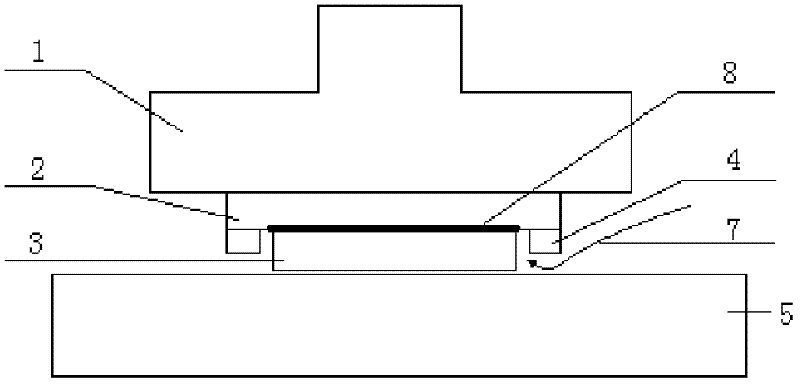

Anti-corrosion method for the back of a single-sided polished wafer

InactiveCN102263024AReduced backside corrosion ratioProductivity is not affectedSemiconductor/solid-state device manufacturingChemical reactionSurface chemical

The invention discloses an anti-corrosion method for the back of a single-sided polished wafer. Step S1 is adopted: adding a reducing agent to the substrate, and the reducing agent covers the back of the wafer to prevent the chemical reaction between the polishing liquid and the back of the wafer. The method provided by the invention can not only significantly reduce the backside corrosion ratio of the wafer in the single-side polishing process, but also ensure that the production efficiency and production cost are not affected.

Owner:BEIJING TONGMEI XTAL TECH CO LTD

Preparation method of mineral insulated cable porcelain column

The invention discloses a preparation method of a mineral insulated cable porcelain column. According to the method, cellulose with 600-800 polymerization degree is used as a raw material and then subjected to alkalization and etherification under certain technological conditions to obtain an adhesion agent with 50-80mPa*s viscosity. The adhesion agent has appropriate viscosities so that the calcination temperature of the porcelain column can be reduced to 750 DEG C in the later period of porcelain column manufacturing, and energy consumption is greatly reduced; and the adhesion agent can be dissolved in water at normal temperatures, and energy consumption for dissolving the adhesion agent is saved. The preparation method is used for preparing magnesium oxide of the porcelain column, the energy consumption during magnesium oxide producing is reduced, and the production costs of the magnesium oxide is around 2 / 3 of those of electric smelting magnesium oxide. According to the magnesium oxide porcelain column prepared by the preparation method, the density of the final porcelain column is 2.0g / cm<3>, and the weight of the porcelain column can be reduced by 10%-15% without influencing the production rate of the porcelain column. According to the preparation method of the mineral insulated cable porcelain column, the technical problem during a production process of the mineral insulated cable porcelain column is solved, the energy consumption is greatly reduced, and the production costs of the mineral insulated cable porcelain column are reduced.

Owner:SHANGHAI TONNOR MATERIAL SCI

Preparation method of magnesium oxide for insulated cable knob insulator, magnesium oxide and application of magnesium oxide

The invention discloses a preparation method of magnesium oxide for an insulated cable knob insulator, the magnesium oxide and application of the magnesium oxide to preparation of the insulated cable knob insulator. According to the preparation method, the energy consumption in a production process of the magnesium oxide is reduced, and the magnesium oxide production cost is about 2 / 3 of the cost of fused magnesium oxide. The magnesium oxide prepared by the method is used for producing the knob insulator; and under the condition of guaranteeing various performance of the knob insulator, the density of the finally obtained knob insulator is 1.9-2.0 g / cm<3> and the weight of the knob insulator is 10-15 percent. The method is also particularly suitable for preparation of the magnesium oxide for a mineral insulated cable knob insulator.

Owner:SHANGHAI TONNOR MATERIAL SCI

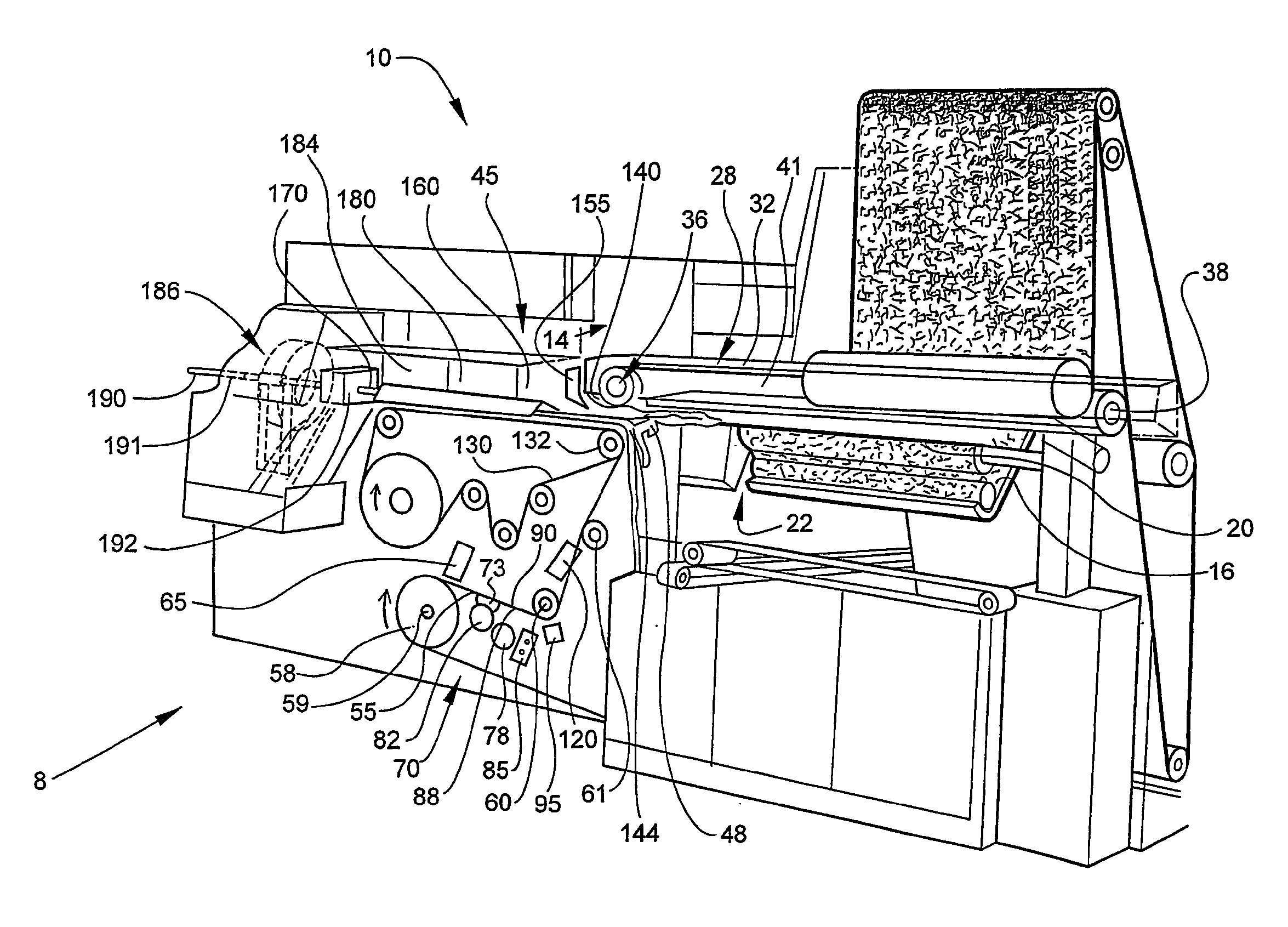

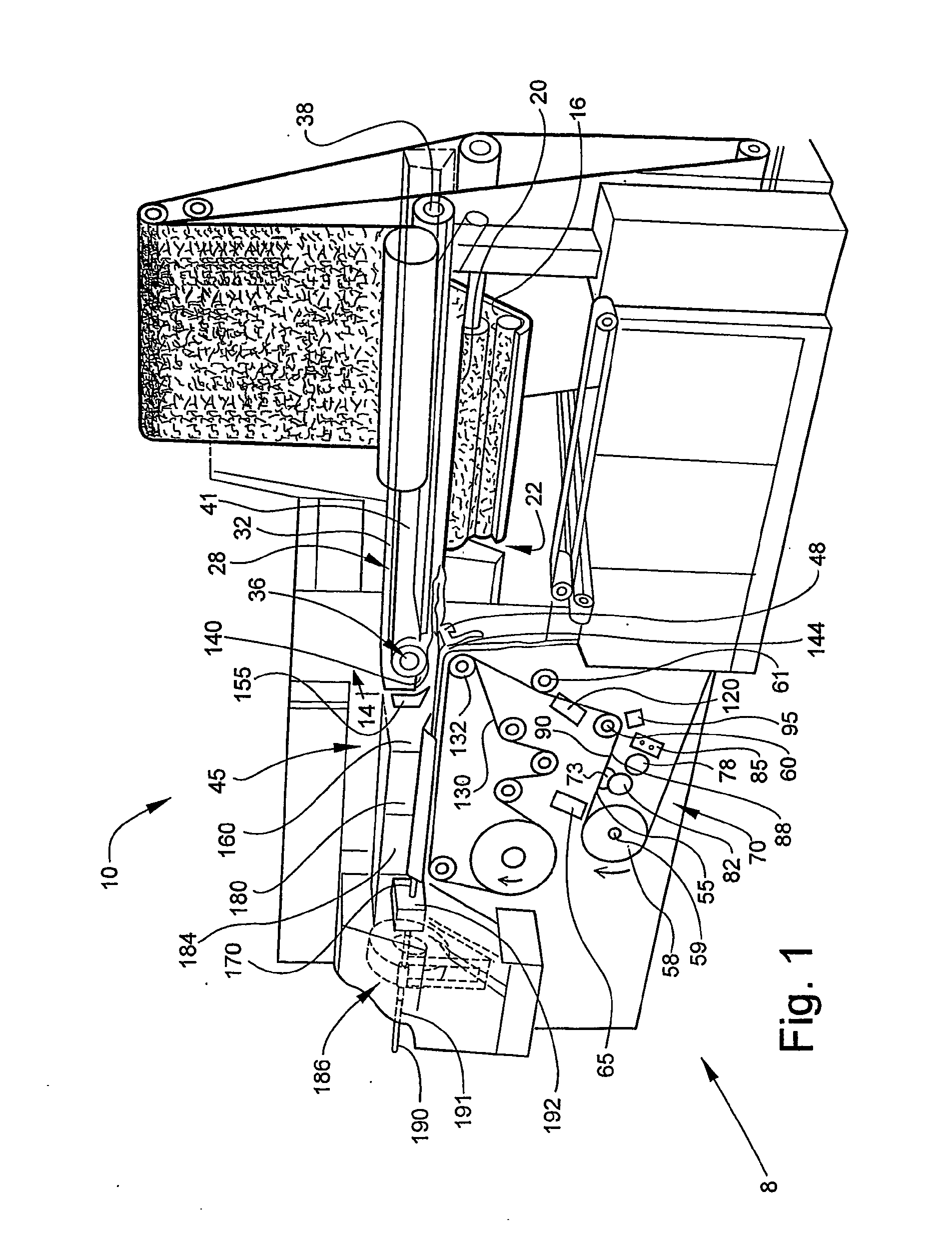

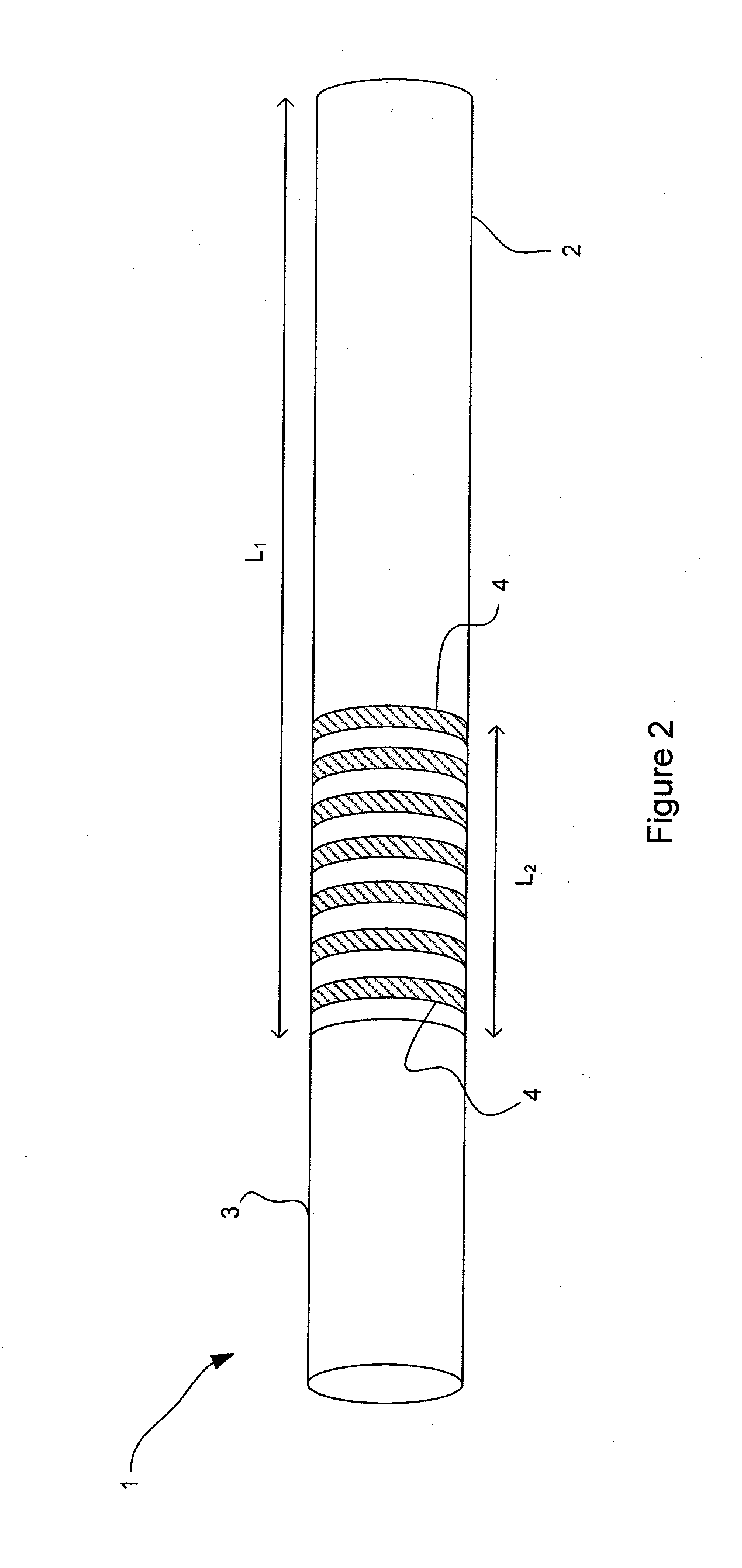

Smoking Articles and Method for Manufacturing Smoking Articles

InactiveUS20110315153A1Productivity is not affectedMinimal modificationNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringLow permeability

The invention relates to a method of manufacturing a plurality of smoking articles, comprising providing a wrapping paper having a permeability of less than 15 CU and applying a burn retardant additive material in a predetermined pattern to the wrapping paper. The wrapping paper is wrapped about a tobacco material to form a wrapped rod and the wrapped rod is cut to form the plurality of smoking articles. The invention also relates to a smoking article manufactured by the method, wherein the wrapping paper has a permeability of less than 15 CU in areas without the burn retardant additive and a lower permeability in areas where the additive is applied.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

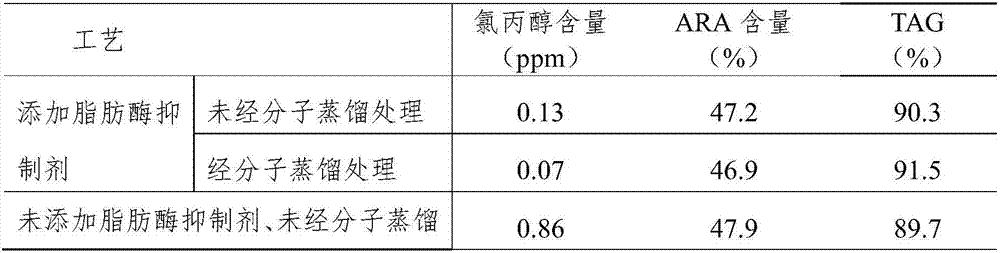

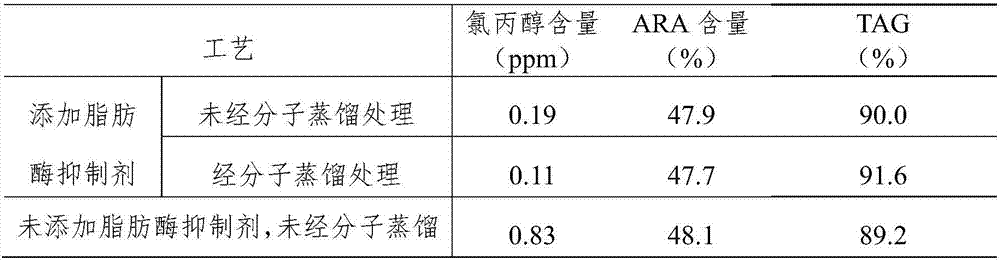

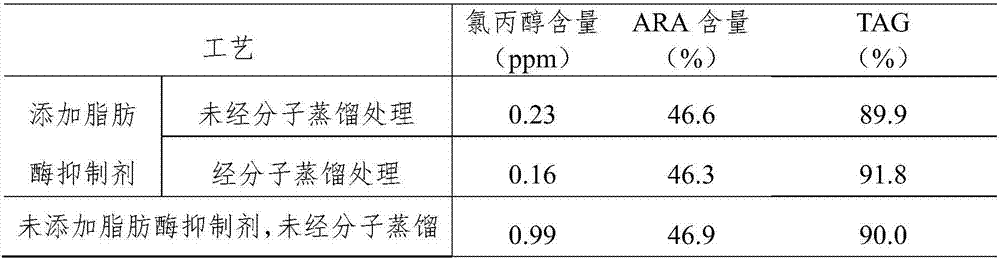

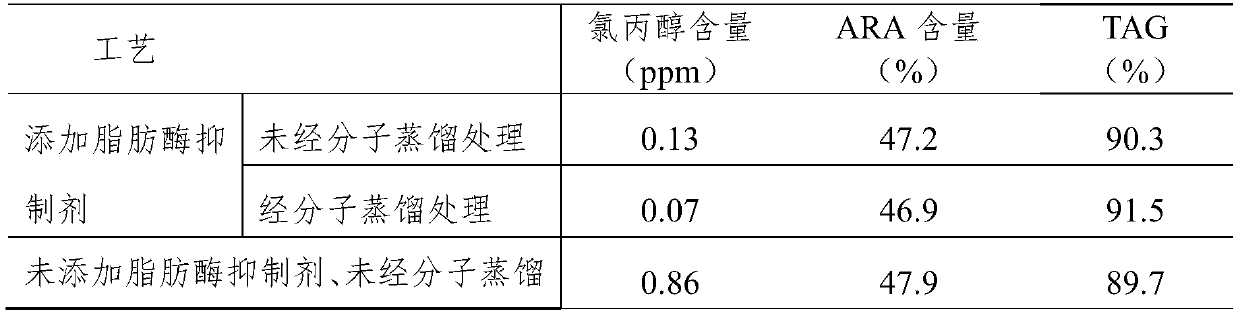

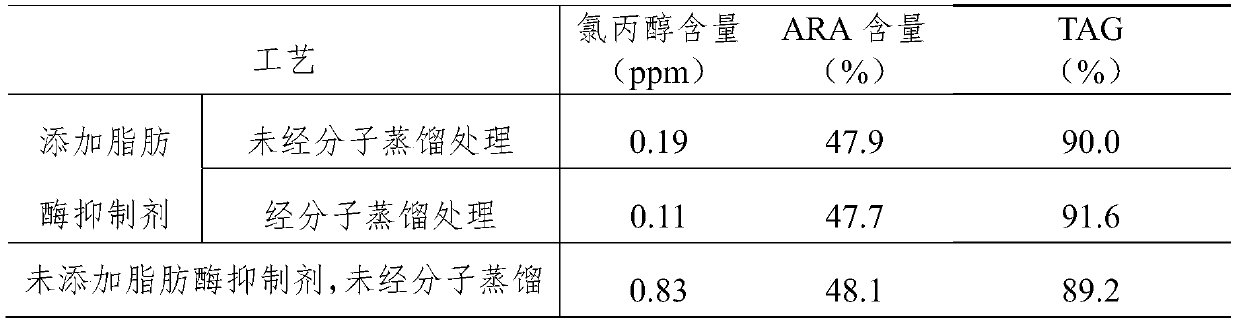

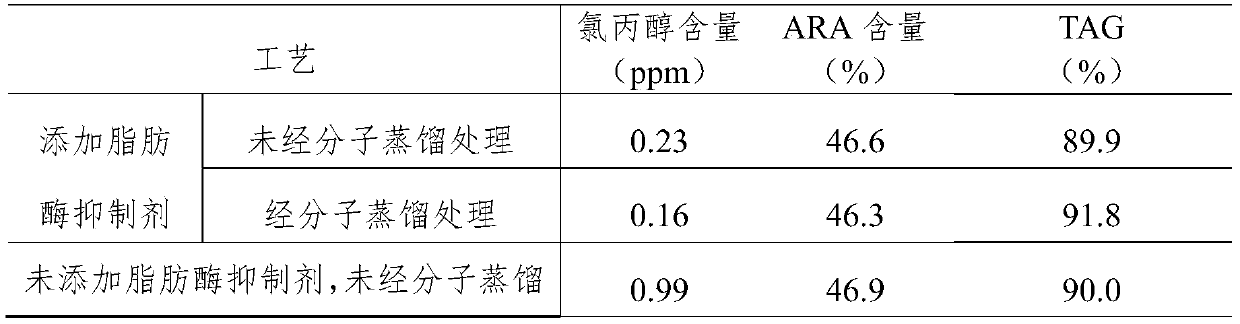

Low-chloropropanol microbial oil and method for preparing same

ActiveCN107418982AGood applicabilityReduced chloropropanol contentMicroorganism based processesFermentationIntestinal Lipase InhibitorChemistry

The invention provides low-chloropropanol microbial oil and a method for preparing the same. Lipase inhibitors are added into fermentation broth fermented from microbial strains, and extraction, refining and deodorization treatment is carried out, so that the contents of glycidyl ester and / or chloropropanol in the obtained microbial oil can be reduced; the activity of lipases in microbial cells in the fermentation broth can be inhibited by the lipase inhibitors. Compared with the prior art, the low-chloropropanol microbial oil and the method have the advantages that the technical problems of required additional corresponding treatment procedures when the content of chloropropanol is about to be reduced and the high content of chloropropanol in final products can be solved; the microbial oil is low in chloropropanol content, treatment technologies are simple, and existing technological processes do not need to be changed.

Owner:CABIO BIOTECH WUHAN CO LTD

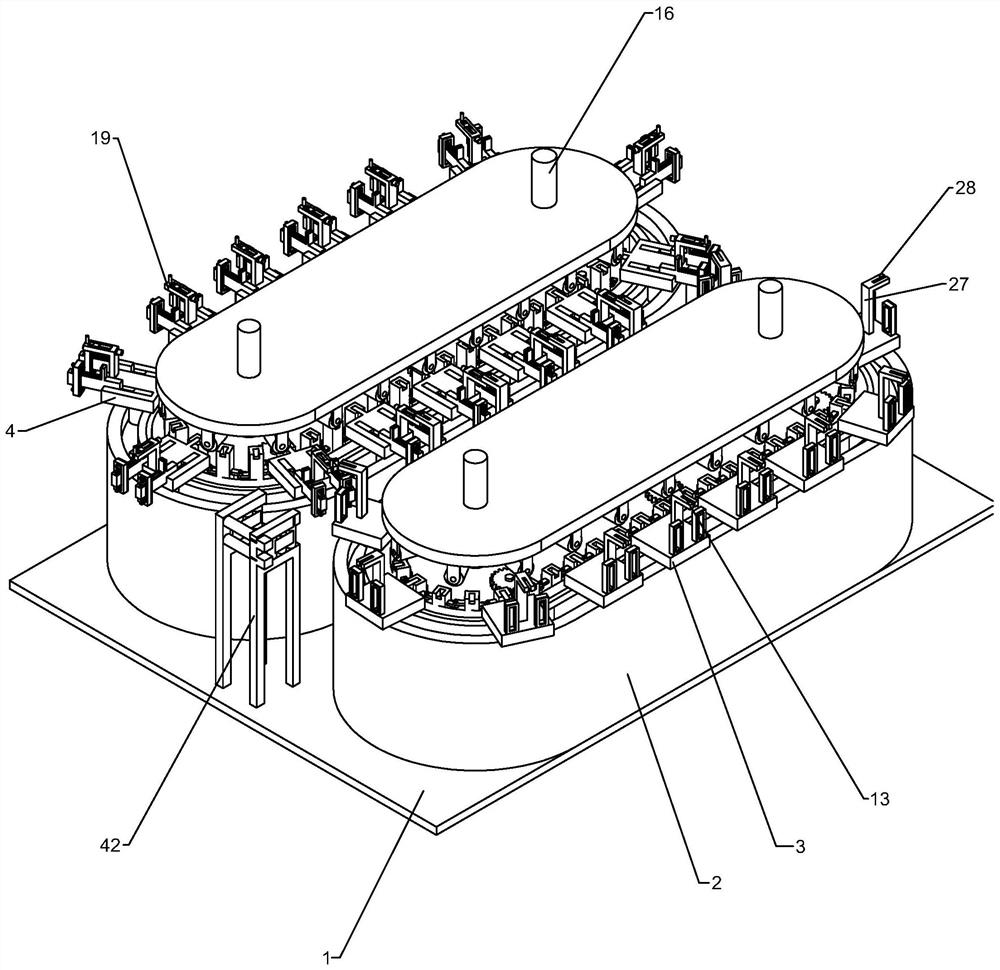

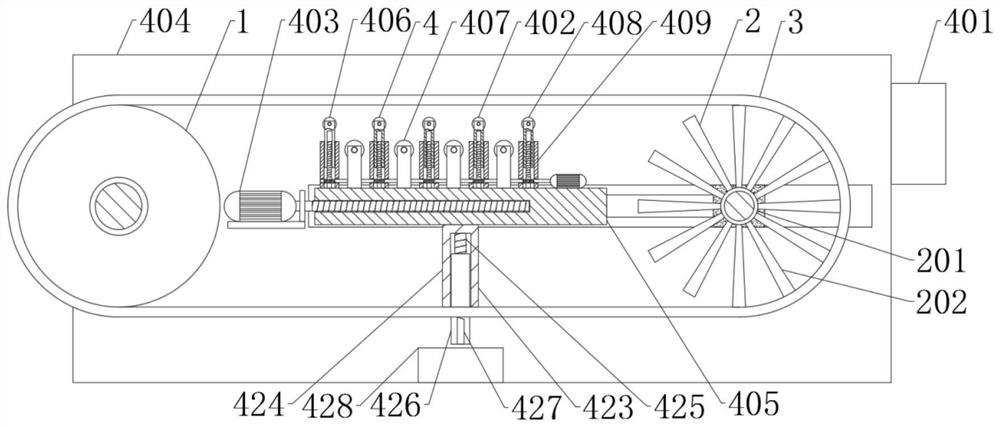

Yarn monitoring system for automatic gun-tufted blanket weaving machine

InactiveCN111549458AAvoid pile count reductionPrevent surface density reductionTufting apparatusTuftingLaser sensor

The invention belongs to the technical field of carpet production, and provides a yarn monitoring system for an automatic gun-tufted blanket weaving machine. The yarn monitoring system comprises a rotating encoder, yarn breakage alarms, a visual sensor, wire passing holes and a control cabinet. The rotating encoder is mounted at the bottom of a pay-off frame and is used for detecting the use amount of yarn spool yarns. The multiple yarn breakage alarms are arranged and mounted in pay-off hole positions of the pay-off frame and used for detecting the breakage of the yarns. The visual sensor ismounted between the pay-off frame and a wire collection hole and used for detecting the number of the winding yarns. The wire passing holes are located between the wire collection hole and a tractionwire feeder and used for detecting the joint size. A laser sensor is mounted outside a gun-tufted box and used for detecting the breakage of tufted threads. A controller connected with an inductor isarranged in the control cabinet. By the adoption of the yarn monitoring system, the yarn conditions that the yarn is used up, the yarn is broken and missed, and the thread connecting head is too largecan be detected automatically in the process of blanket weaving of a bayonet tufting machine, so that the carpet production quality is effectively ensured, and defective products are avoided.

Owner:WEIFANG VOCATIONAL COLLEGE

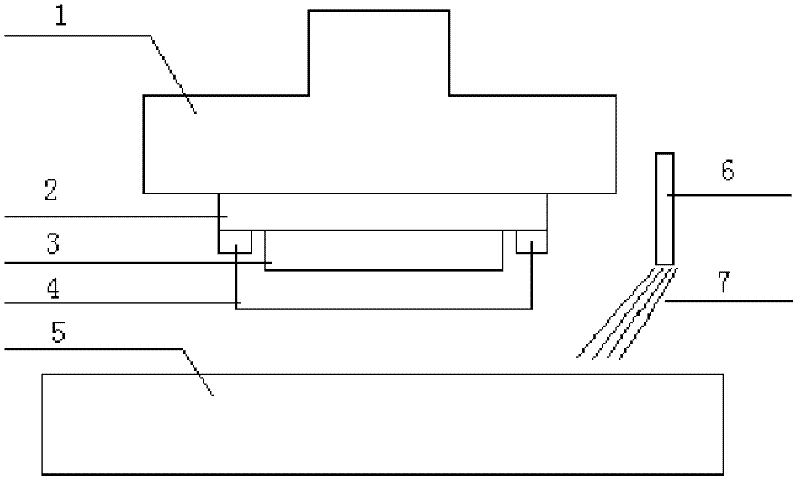

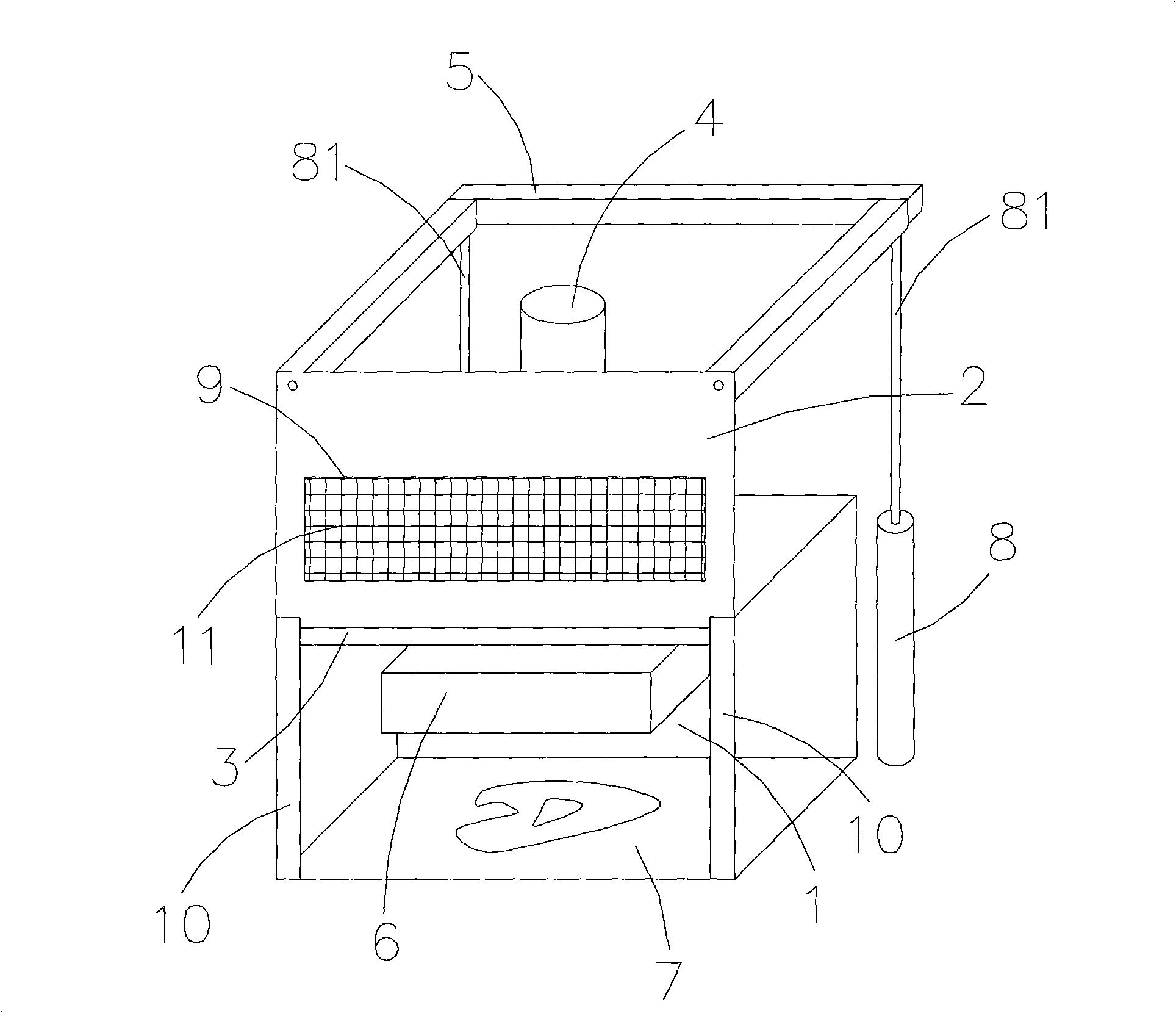

Embossment system with radio frequency interference protection

ActiveCN101288512APrevent electromagnetic radiation leakageProtect personal healthShoemaking devicesRadio frequencyPiping

The invention discloses an embossing system with radio frequency interference protection which comprises an enclosed metal studio enclosing an embossing die. In the front of the enclosed metal studio, a sliding cover is installed. During embossing, materials to be processed can conveniently be transported into the metal studio and the studio can shut quickly; high frequency current is conveyed from power supply to a current-carrying piping with shield effect of an embossing press. The studio is equipped with lighting, and a watch window is arranged in the front of the studio, which can observe the situation of processing safely and conveniently. The embossing system with radio frequency interference protection of the invention can prevent the leaking of high frequency radiation from a processor to ambient environment during the embossing, which can be extensively applied to embossing presses.

Owner:ORISOL ASIA

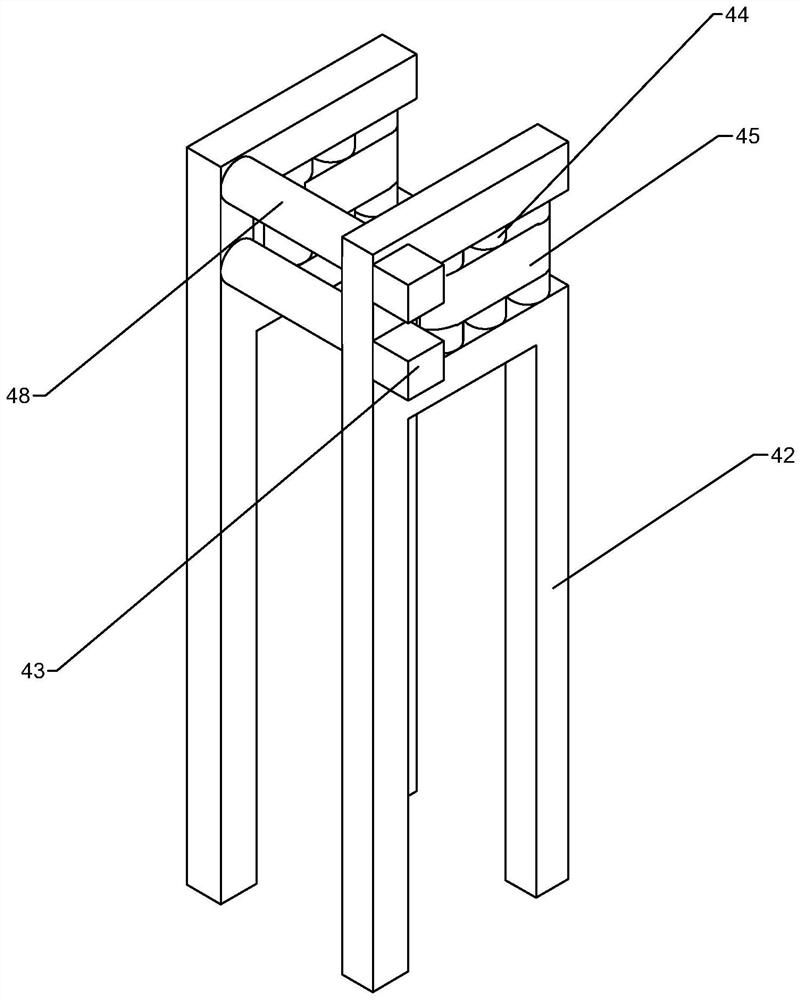

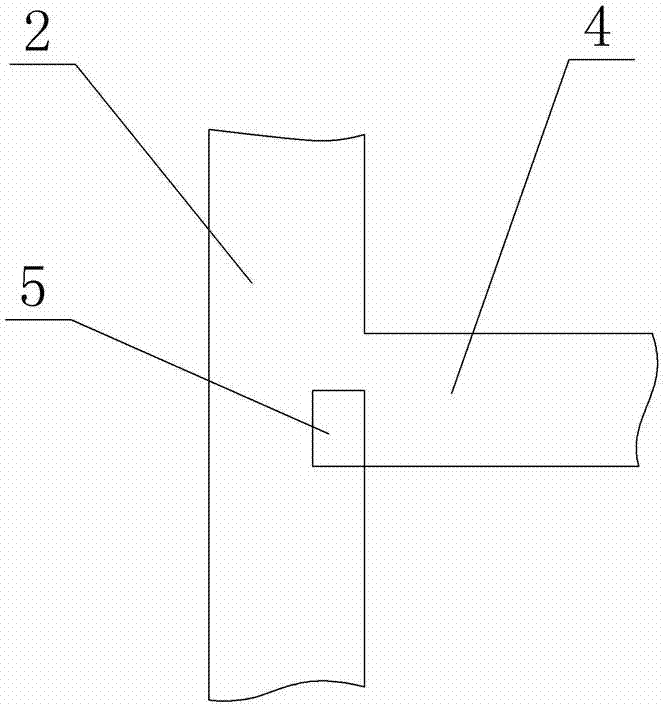

Mark pressing machine

InactiveCN109501388AEasy to adjustNo need to disassembleMechanical working/deformationEngineeringMechanical engineering

The invention discloses a mark pressing machine. The mark pressing machine comprises a rack, an upper pressing roller, a lower pressing roller, a first driving device and a second driving device, wherein the upper pressing roller and the lower pressing roller are rotatably arranged on the rack, a mark pressing gap is formed between the upper pressing roller and the lower pressing roller, the rackis provided with adjusting mechanisms, the upper pressing roller comprises an upper pressing roller body and a first rotating shaft, the lower pressing roller comprises a lower pressing roller body and a second rotating shaft, the rack is provided with two first rotating holes for the two ends of the first rotating shaft penetrating through and further provided with two long-strip-shaped second rotating holes, the second rotating holes are internally and movably provided with bearings arranged and installed on the periphery of the second rotating shaft in a sleeving manner and further internally provided with elastic pressure-bearing parts, the bottoms of the elastic pressure-bearing parts are connected with the bottoms of the corresponding second rotating holes, the tops of the elastic pressure-bearing parts abut against bearing outer rings of the corresponding bearings, each adjusting mechanism comprises a supporting rod, a rolling component and a third driving device, and the rolling components are installed at the upper ends of the corresponding supporting rods and are in rolling contact with the surface of the lower pressing roller. The mark pressing machine has the advantageof convenient adjustment of the mark pressing gap.

Owner:安徽瀚洋纸品印刷有限公司

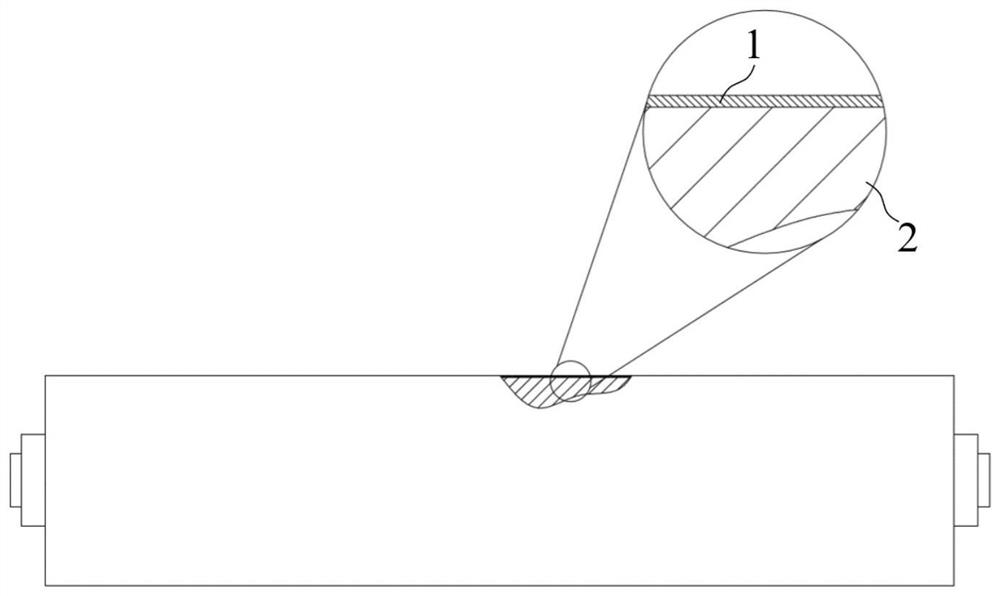

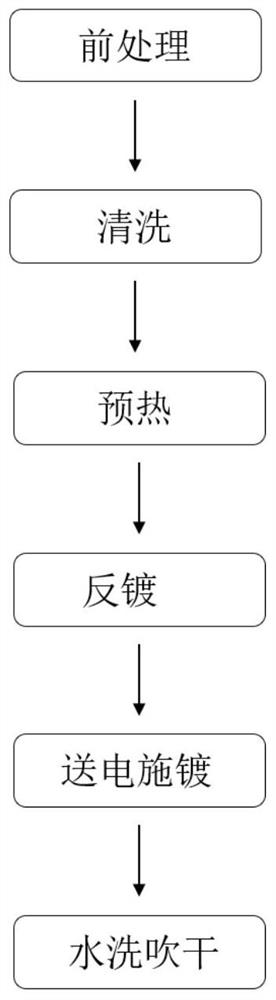

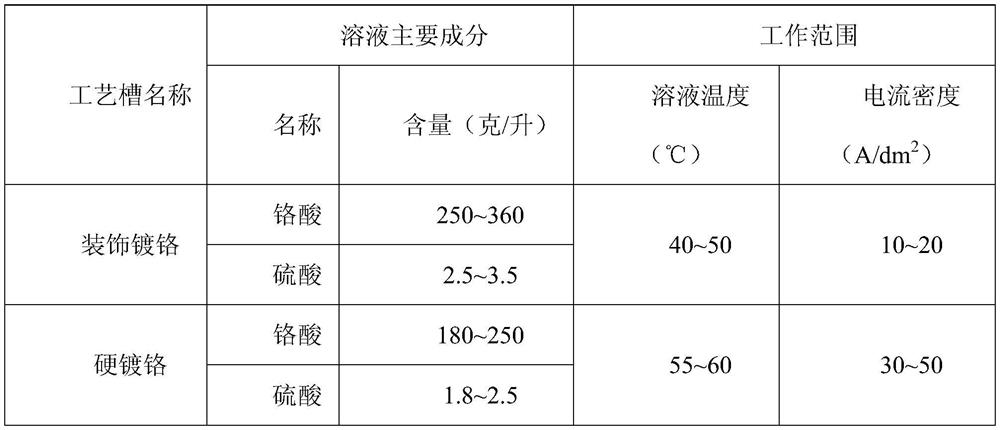

Temper mill applying chromium-plated roller

PendingCN112222194AIncrease the temperature of the roll bodyGuaranteed smoothRollsMetal rolling arrangementsStrip steelChrome plating

The invention discloses a temper mill applying a chromium-plated roller, and belongs to the field of forming equipment. The roller of the temper mill adopts the chromium-plated roller with the diameter of 450 mm. Through the improvement of the present invention, the single rolling time of the roller can be prolonged by 3-10 times, the roller replacement downtime is shortened, the operation rate isimproved, the abrasion resistance of the chromium-plated roller is improved, the uniformity of the surface roughness of strip steel in the rolling period is improved, the surface hardness of the chromium-plated roller is further improved, roller surface scratches are reduced, the surface quality of the strip steel and the cleanliness of the plate surface are improved, and the lubricating capacityof the roller is improved.

Owner:江苏友富薄板科技有限公司

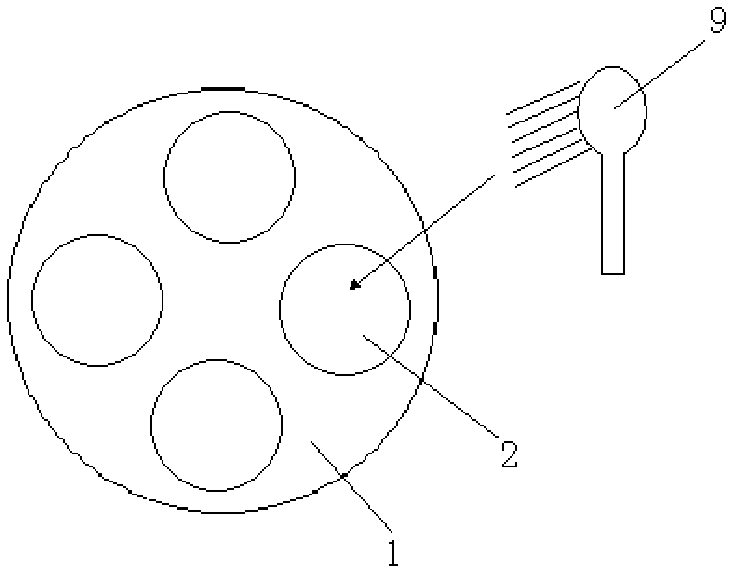

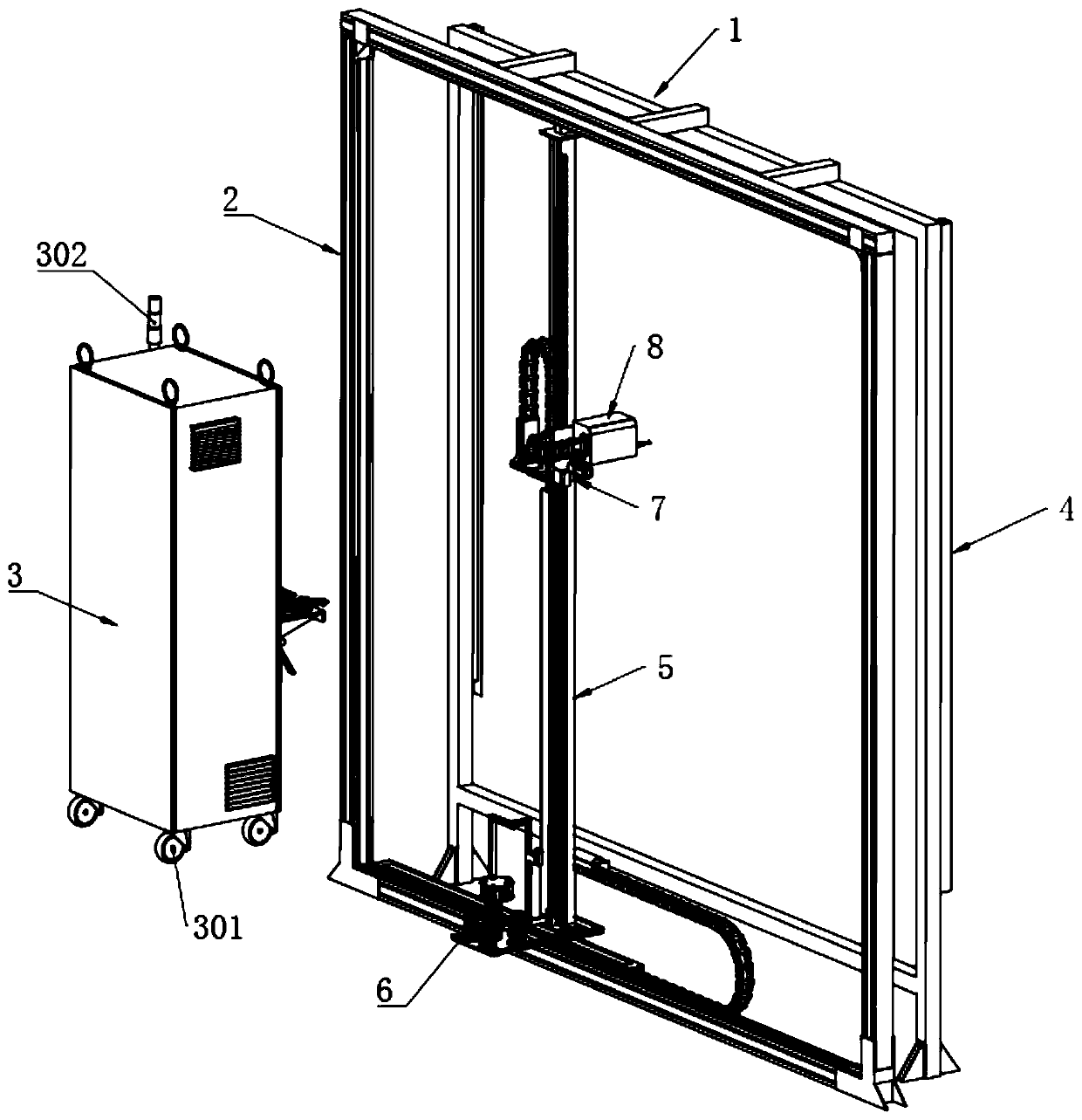

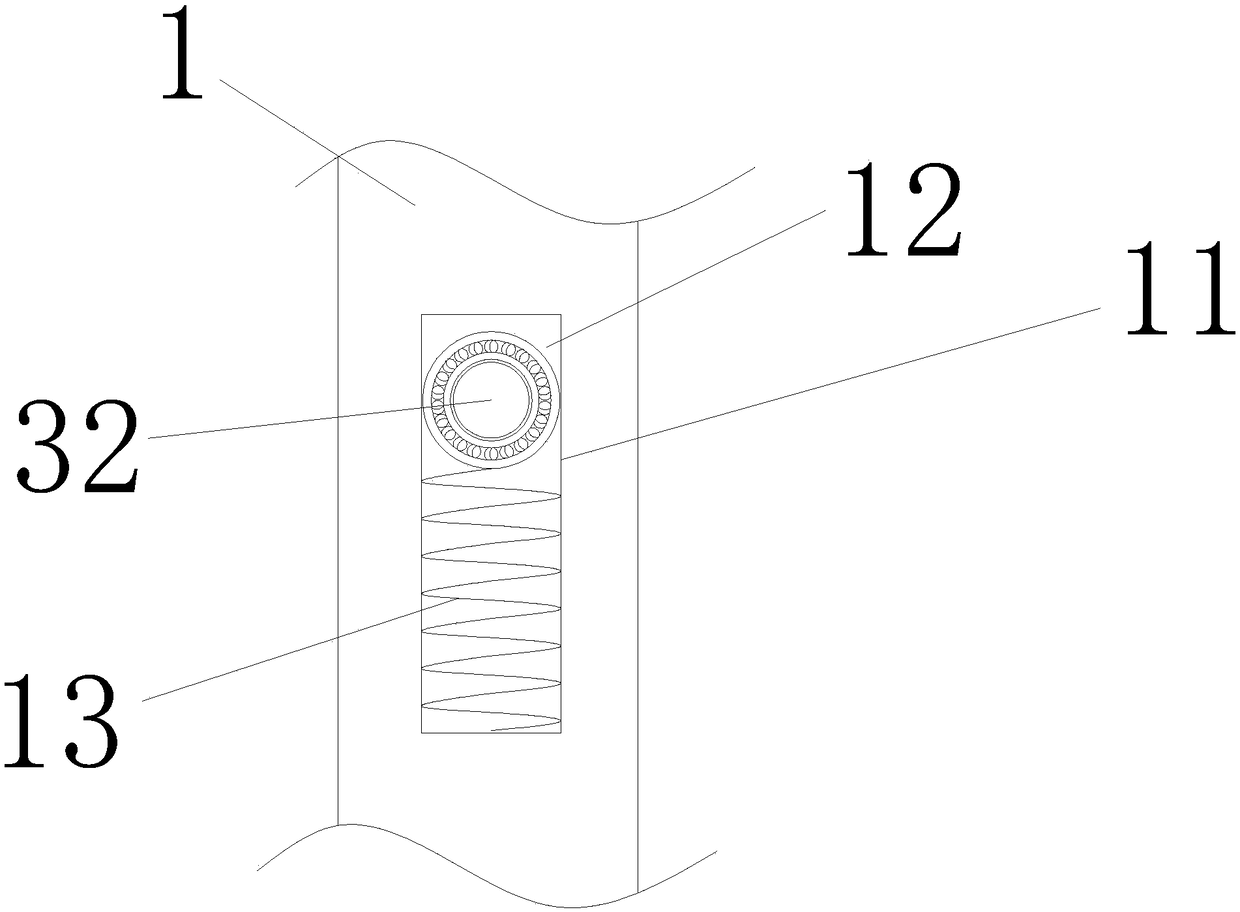

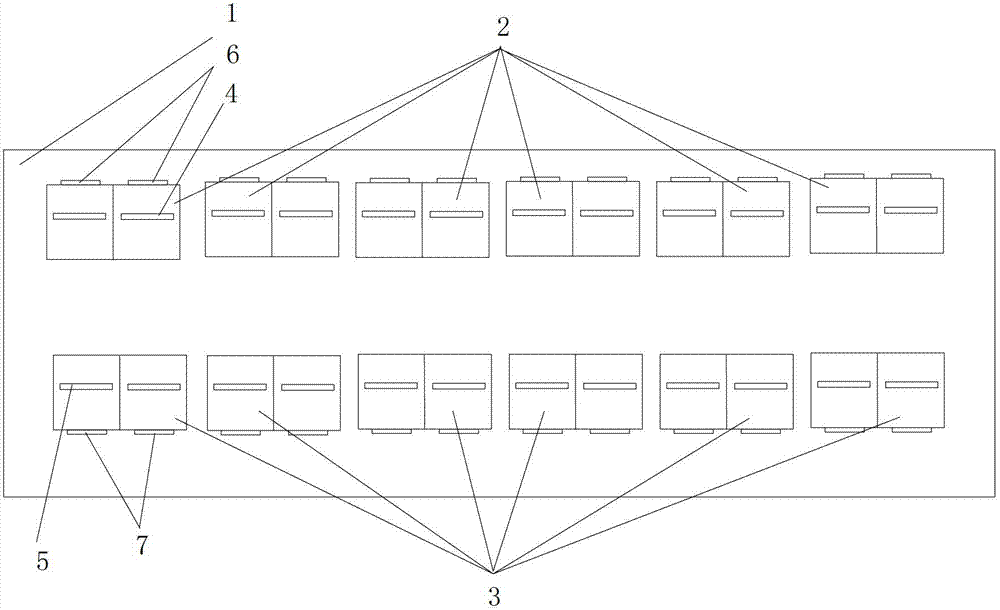

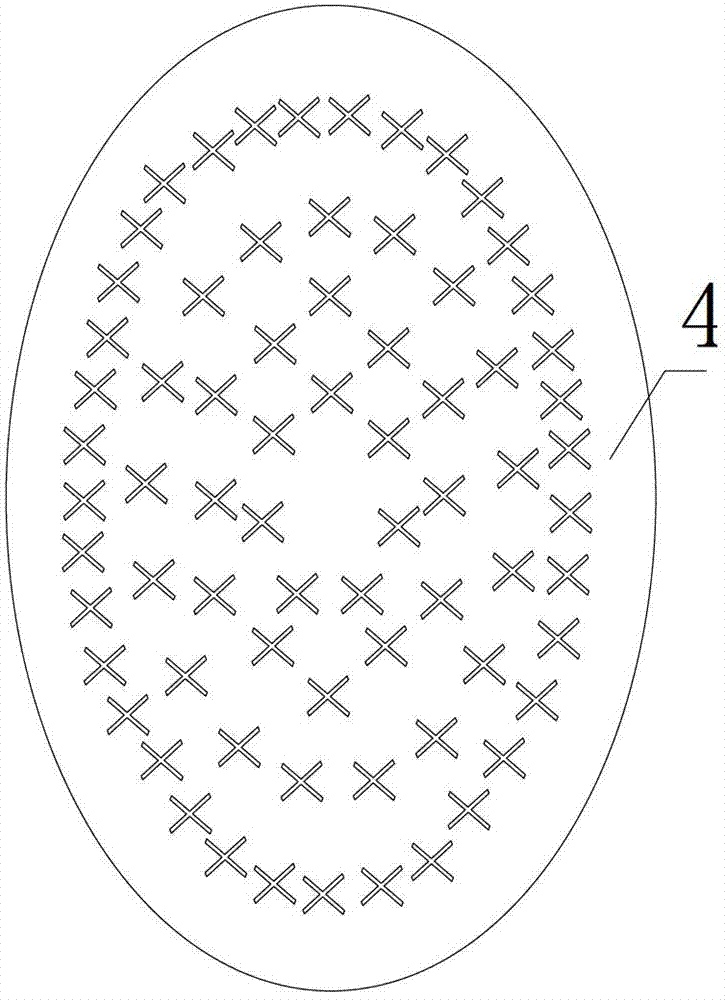

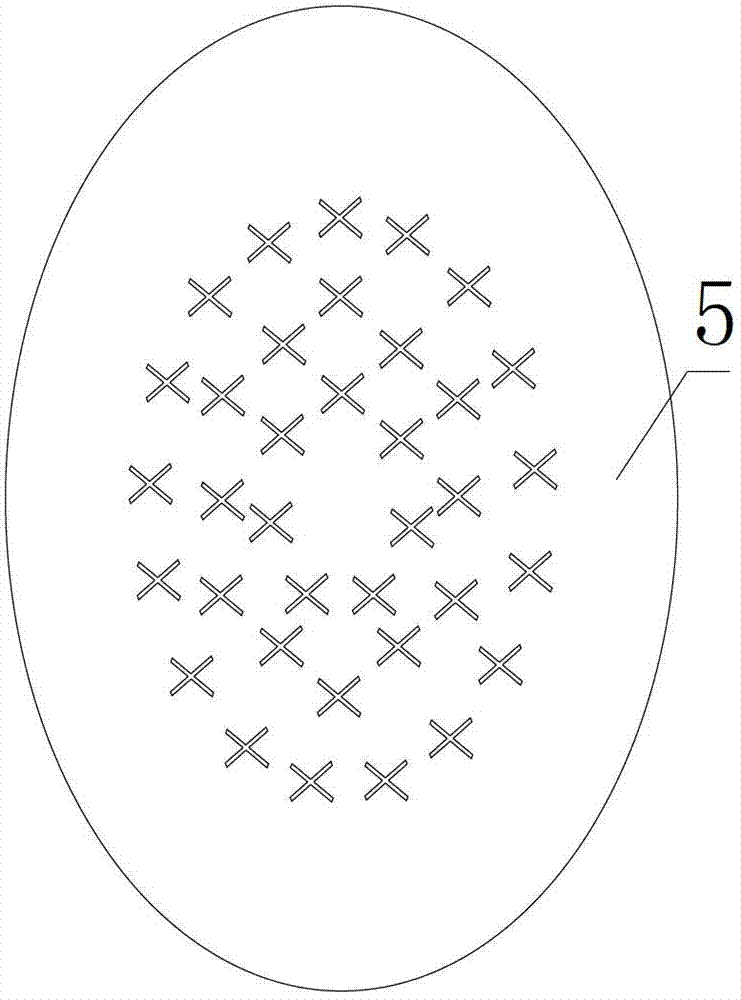

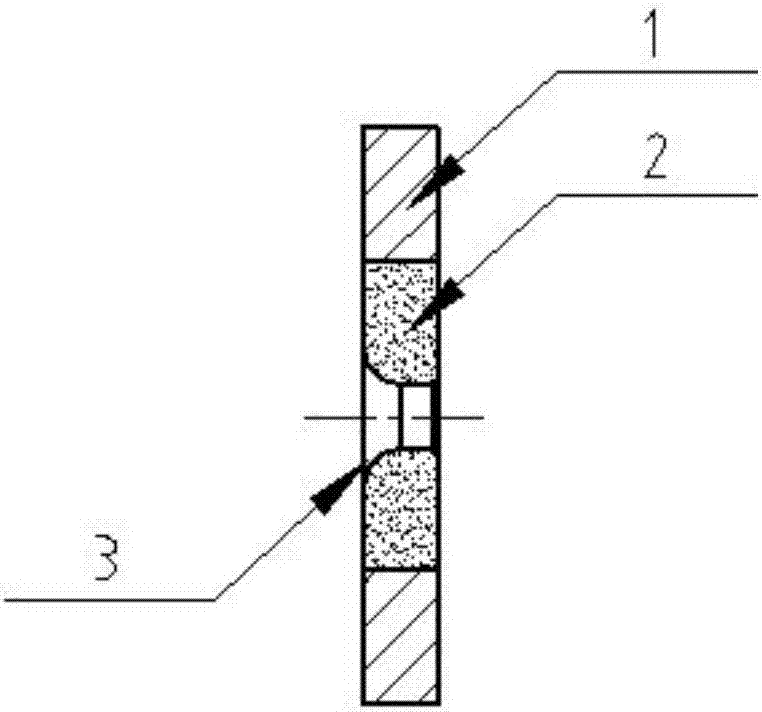

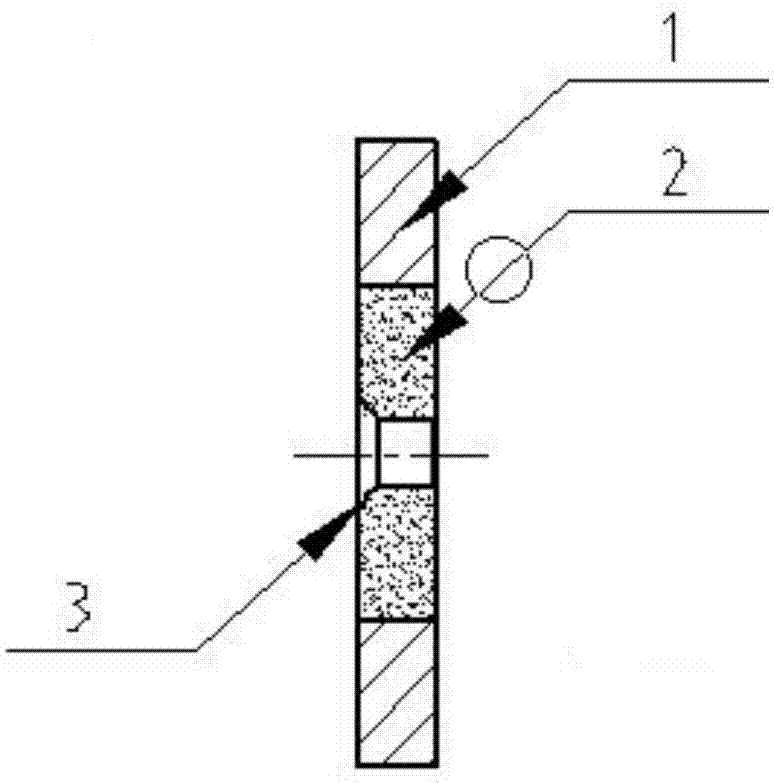

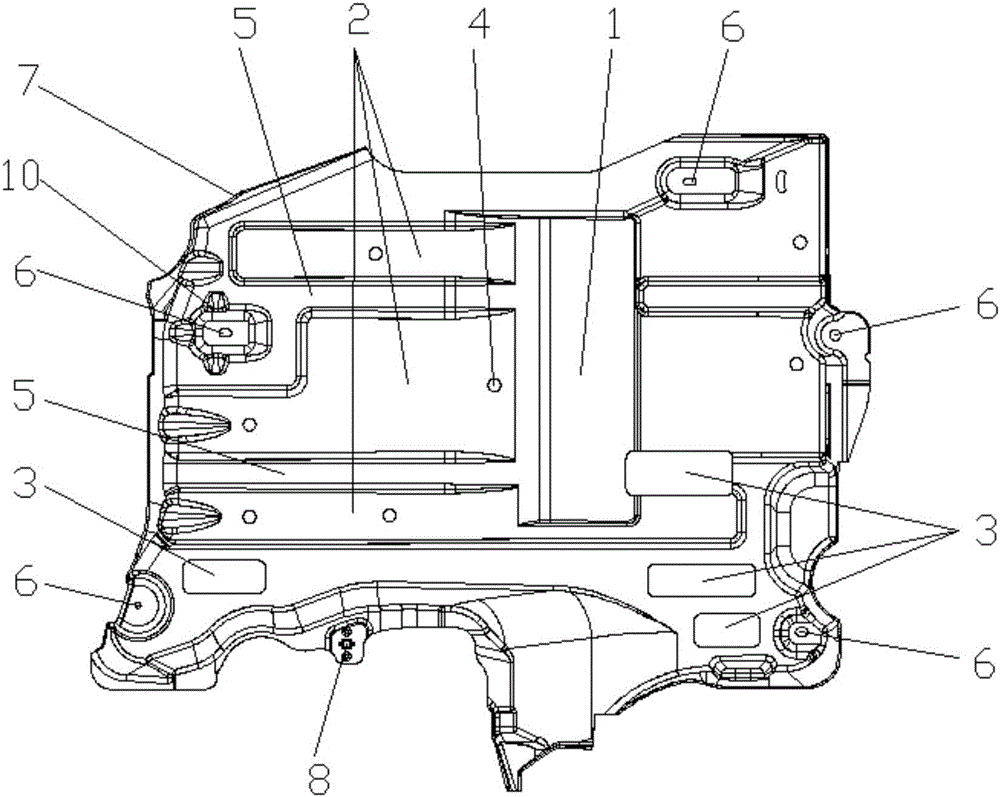

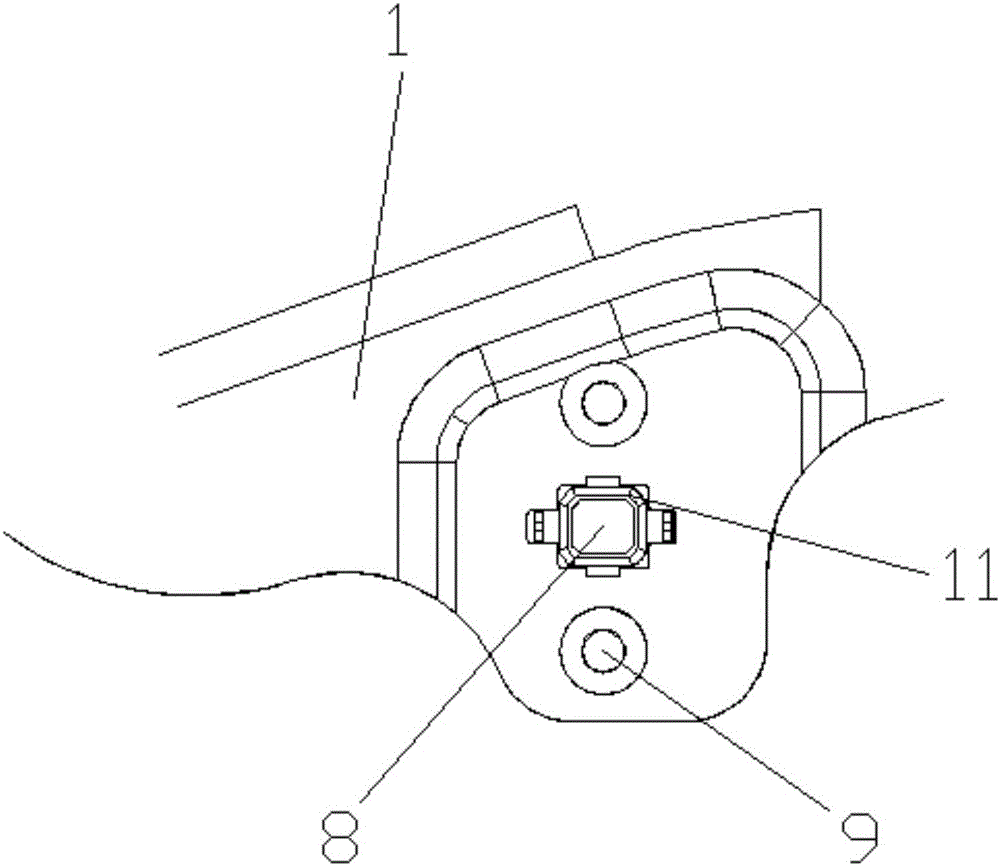

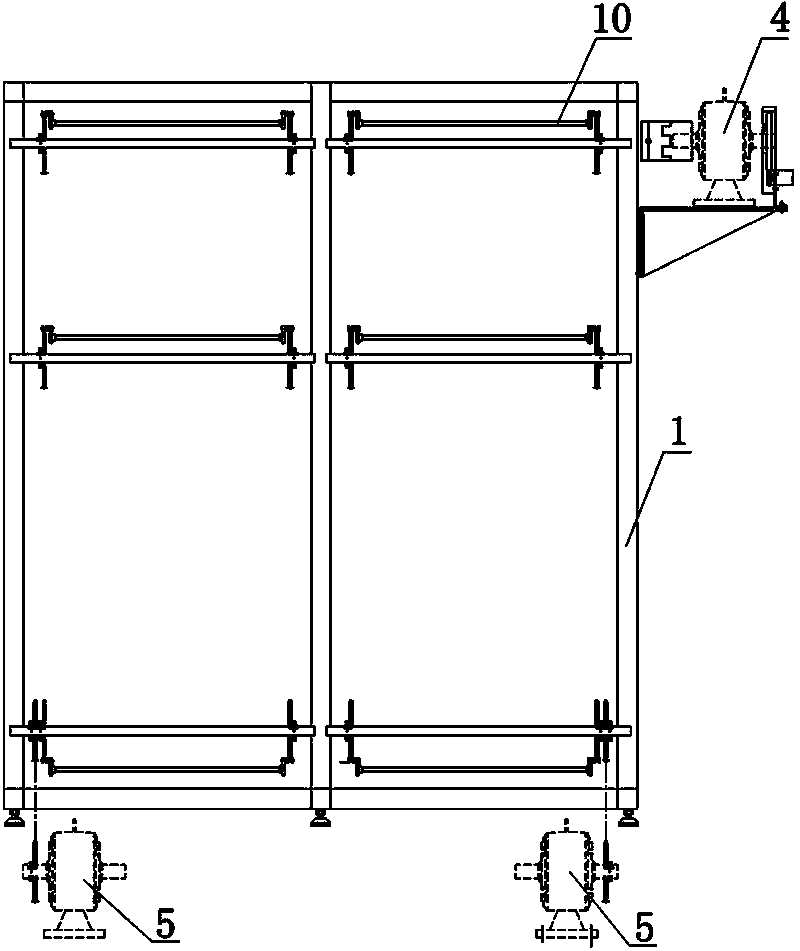

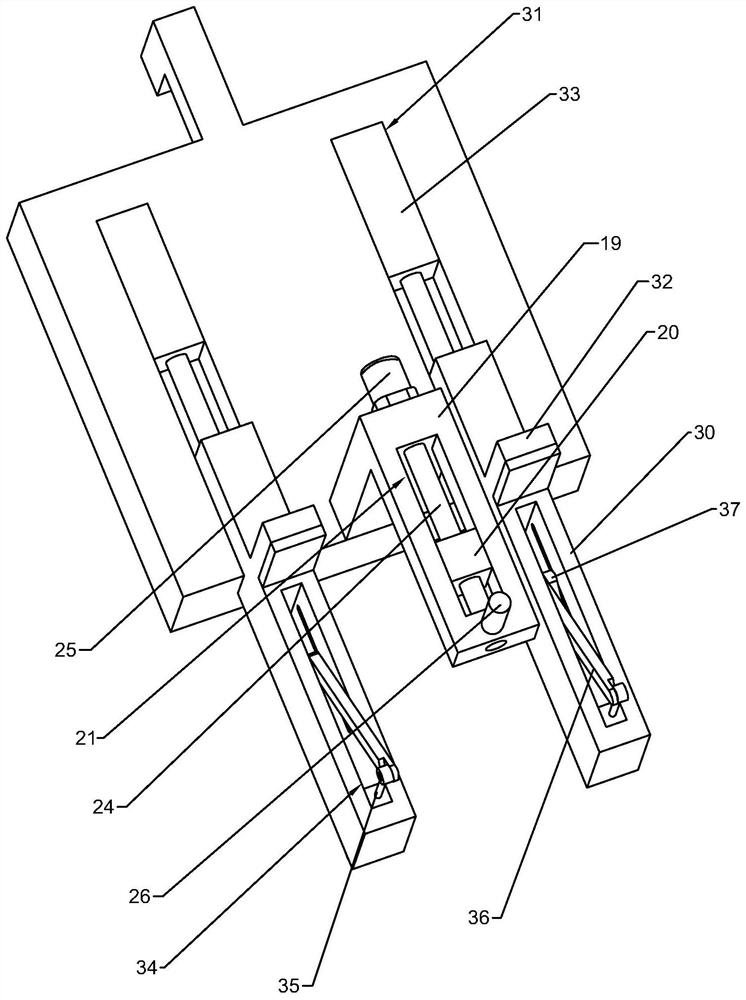

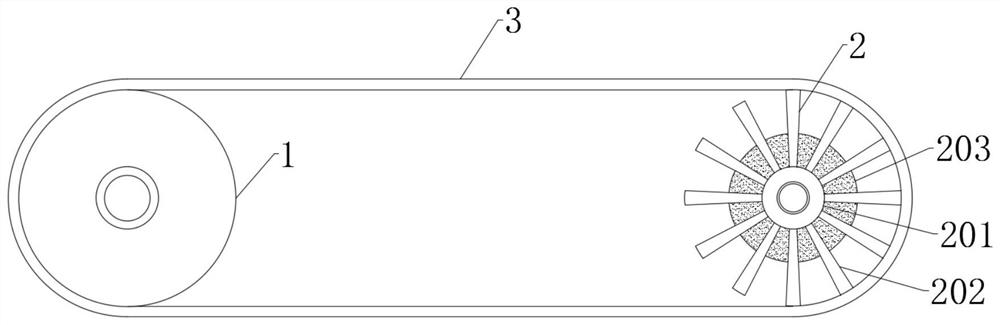

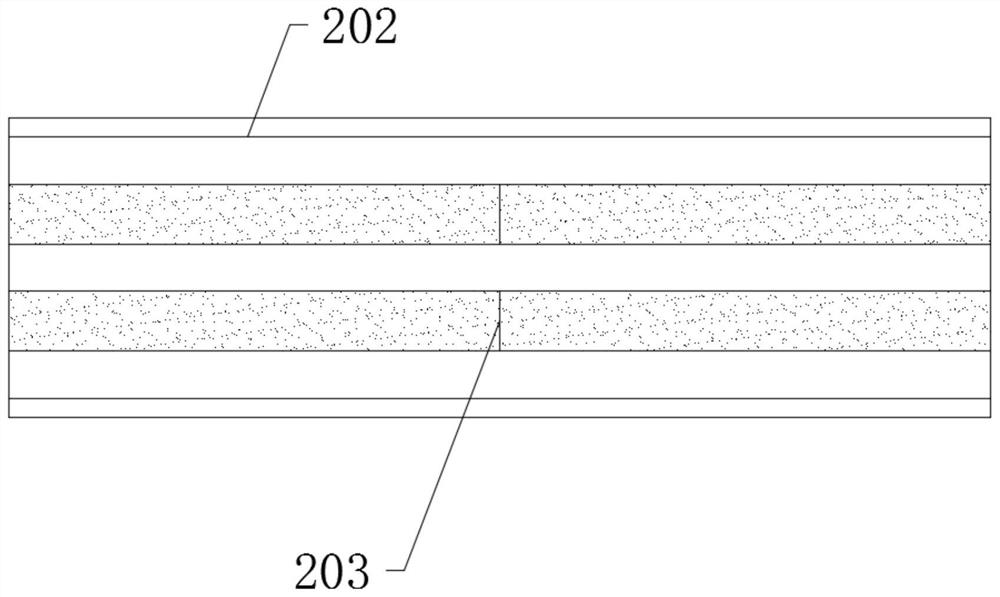

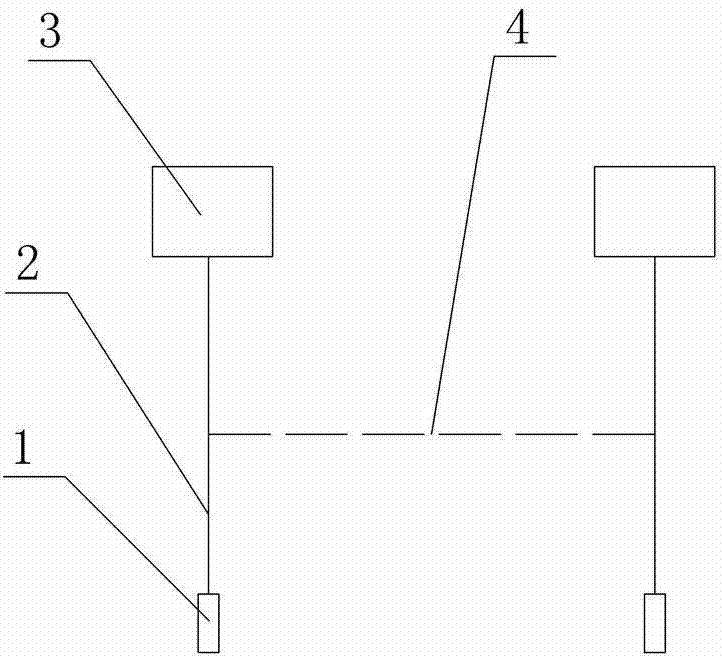

Spinning manifold for manufacturing POY (pre-oriented yarn) and FDY (fully drawn yarn) composite fibers

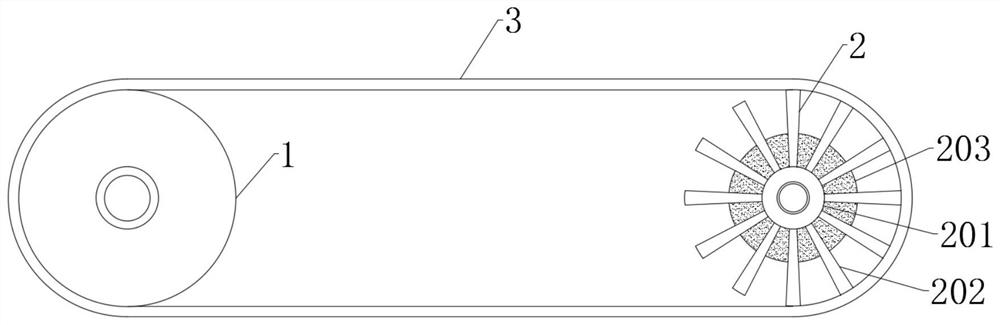

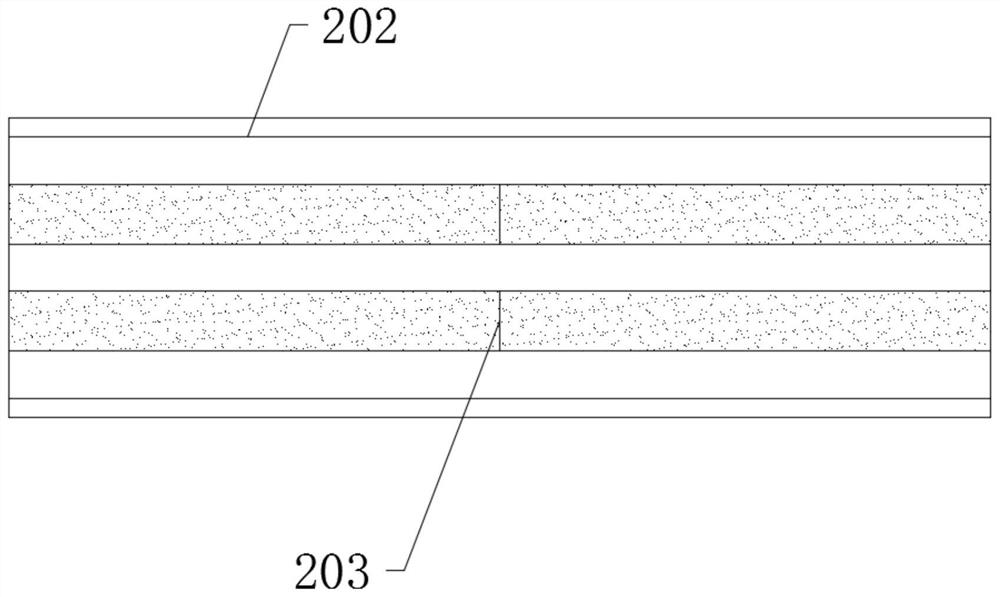

InactiveCN103710771ADoes not affect production efficiencyProductivity is not affectedArtificial thread manufacturing machinesFilament/thread formingYarnFiber

The invention discloses a spinning manifold for manufacturing POY (pre-oriented yarn) and FDY (fully drawn yarn) composite fibers. The spinning manifold comprises a spinning manifold body (1), melt distribution pipes, metering pumps and spinning assemblies. The POY manufacturing spinning assemblies (2) and the FDY manufacturing spinning assemblies (3) are parallelly arranged side by side, each POY manufacturing spinning assembly (2) comprises two spinneret plates (4), and each FDY manufacturing spinning assembly (3) comprises two spinneret plates (5). The spinning manifold has the advantages that the POY and FDY composite yarn productivity and the POY and FDY composite yarn production efficiency can be guaranteed against being affected, so that the quality of obtained products is high, and the moisture absorption and the breathability of fabrics can be obviously improved.

Owner:JIANGSU HUAYA FIBER

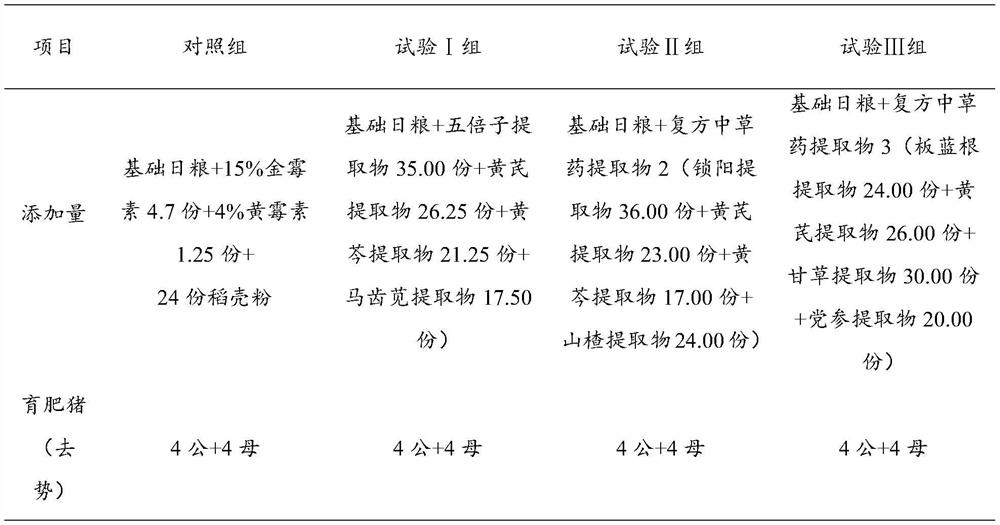

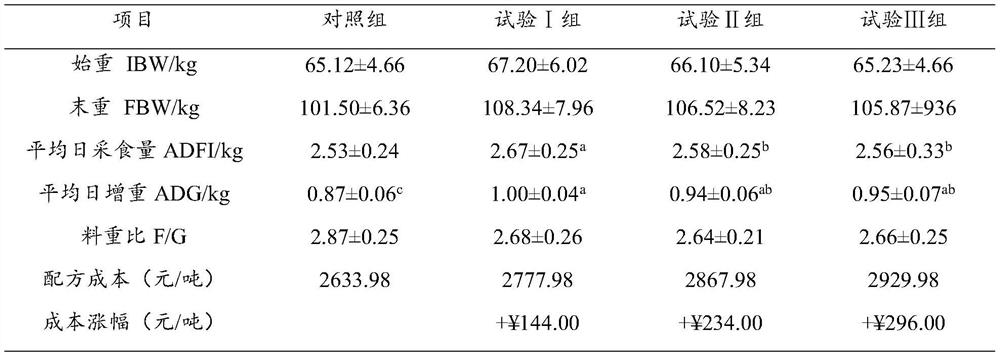

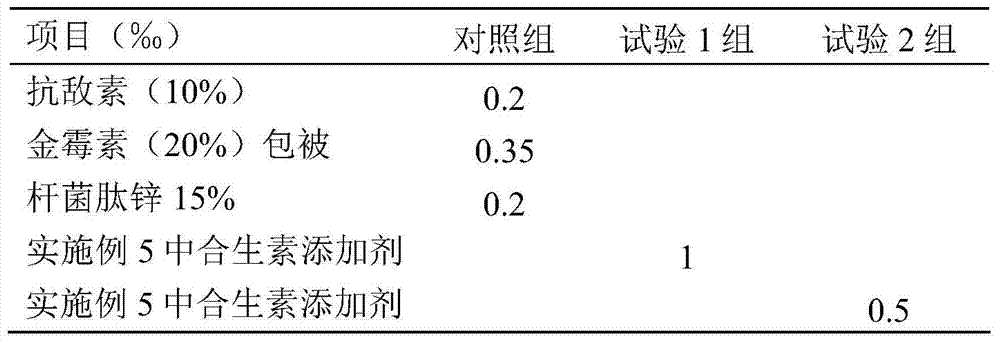

Low-protein traditional Chinese medicine feed capable of replacing antibiotics

ActiveCN112841438AReliable sourceReduce usageAntibacterial agentsAnthropod material medical ingredientsBiotechnologyAnimal science

The invention relates to the technical field of feeds, in particular to a low-protein traditional Chinese medicine feed capable of replacing antibiotics. The invention particularly relates to selection and compatibility of antibiotic substitutes for growing and fattening pigs and a formula design and production process of low-protein daily ration in an SID amino acid balance mode. The feed formula disclosed by the invention has the main characteristics that (1) crude protein of common commercial fattening pigs matched with daily ration is reduced from 16.0% to 13.0% so as to meet the growth requirements of the fattening pigs; (2) varieties of added amino acids are increased; and (3) three antibiotic substitution schemes are emphatically verified, and feeding verification shows that the effect is remarkable, and the cost is within an acceptable range. The feed is reasonable in formula, low in cost, reliable in raw material source, suitable for being used in the pig fattening period after being added, free of influence on production performance, reasonable in cost, capable of reducing use of protein raw materials, free of antibiotic addition, capable of reducing emission of toxic and harmful gases such as ammonia gas in a pig house and capable of improving economic benefits of farmers.

Owner:GANSU AGRI UNIV +1

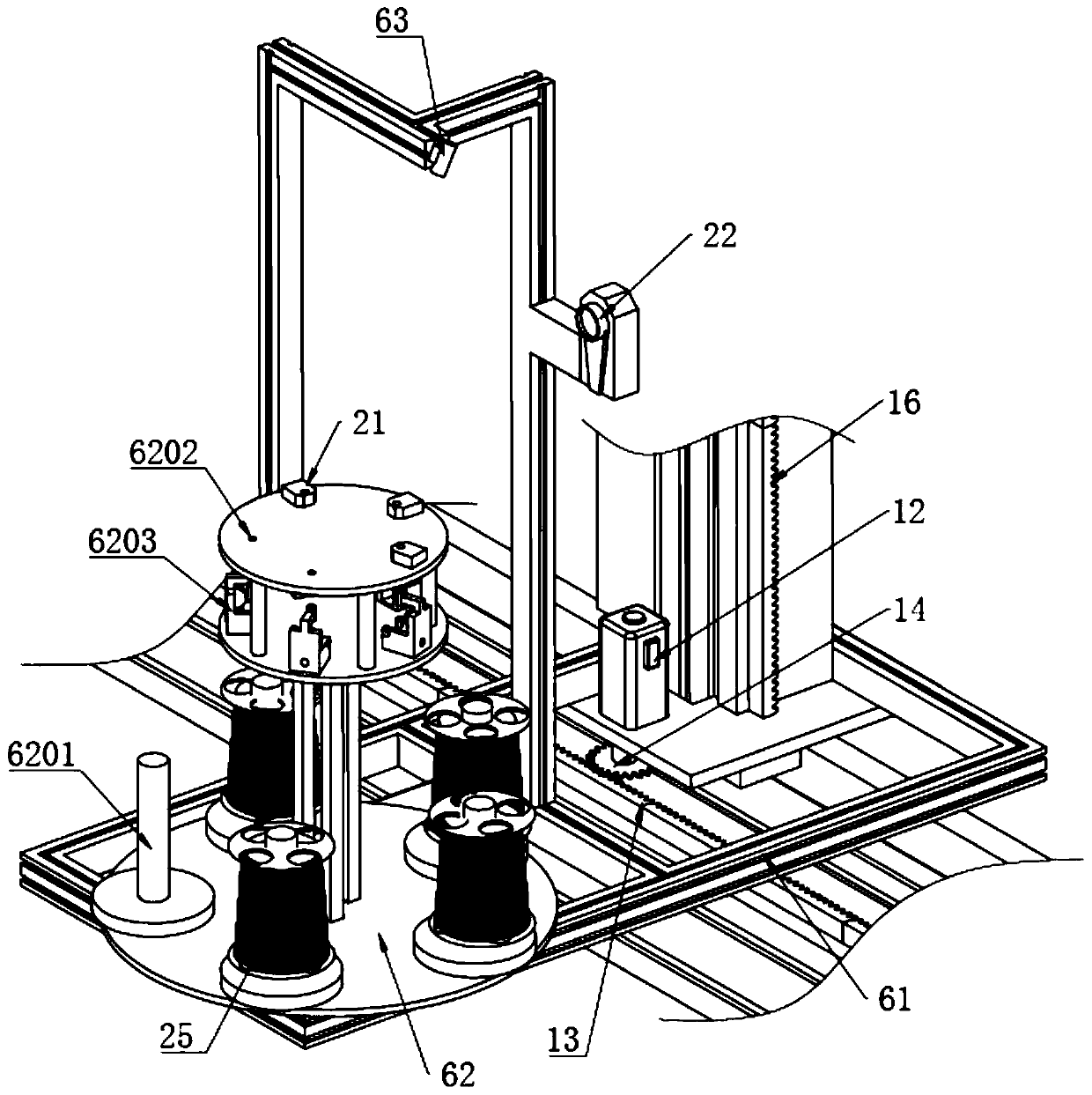

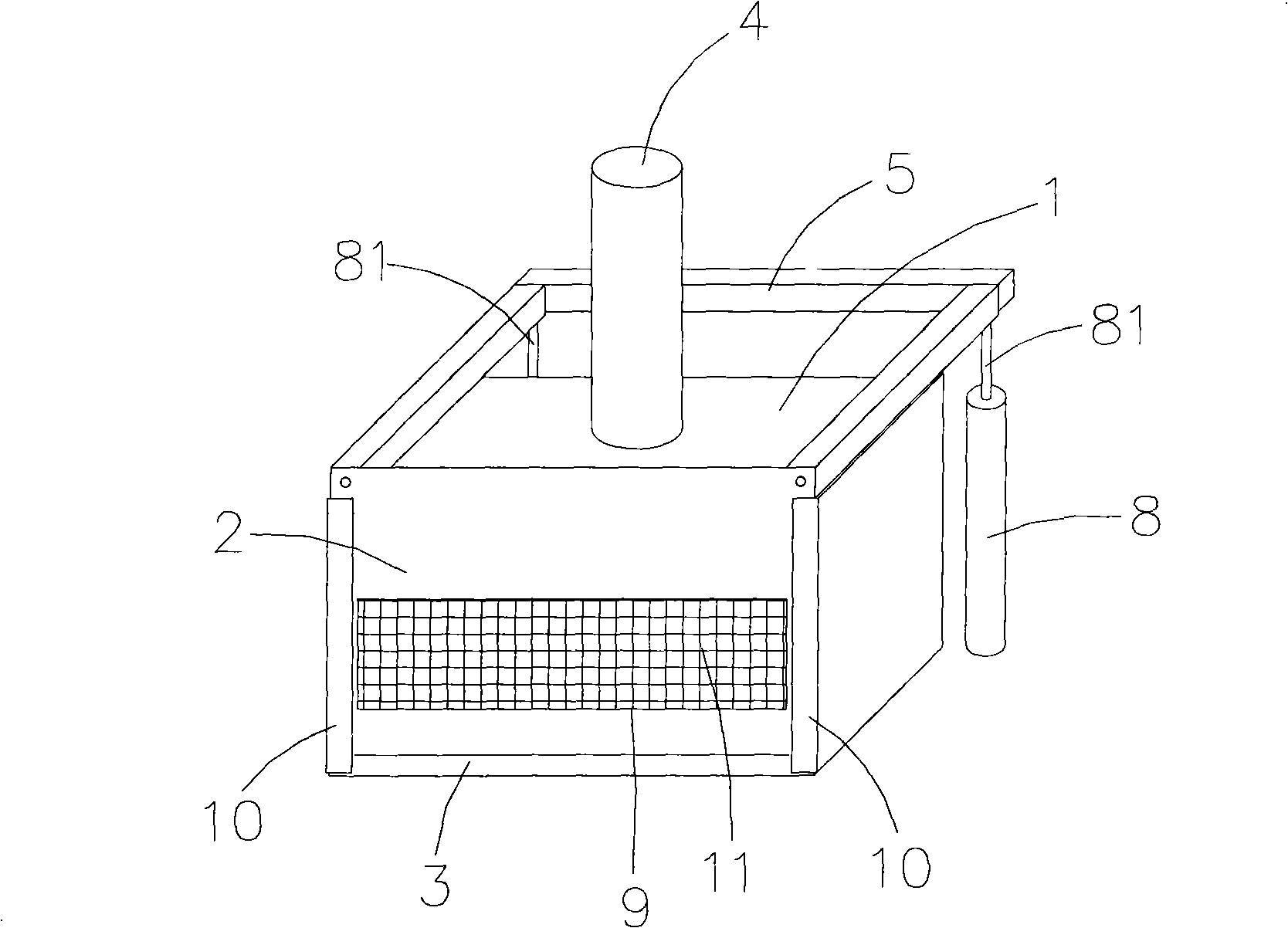

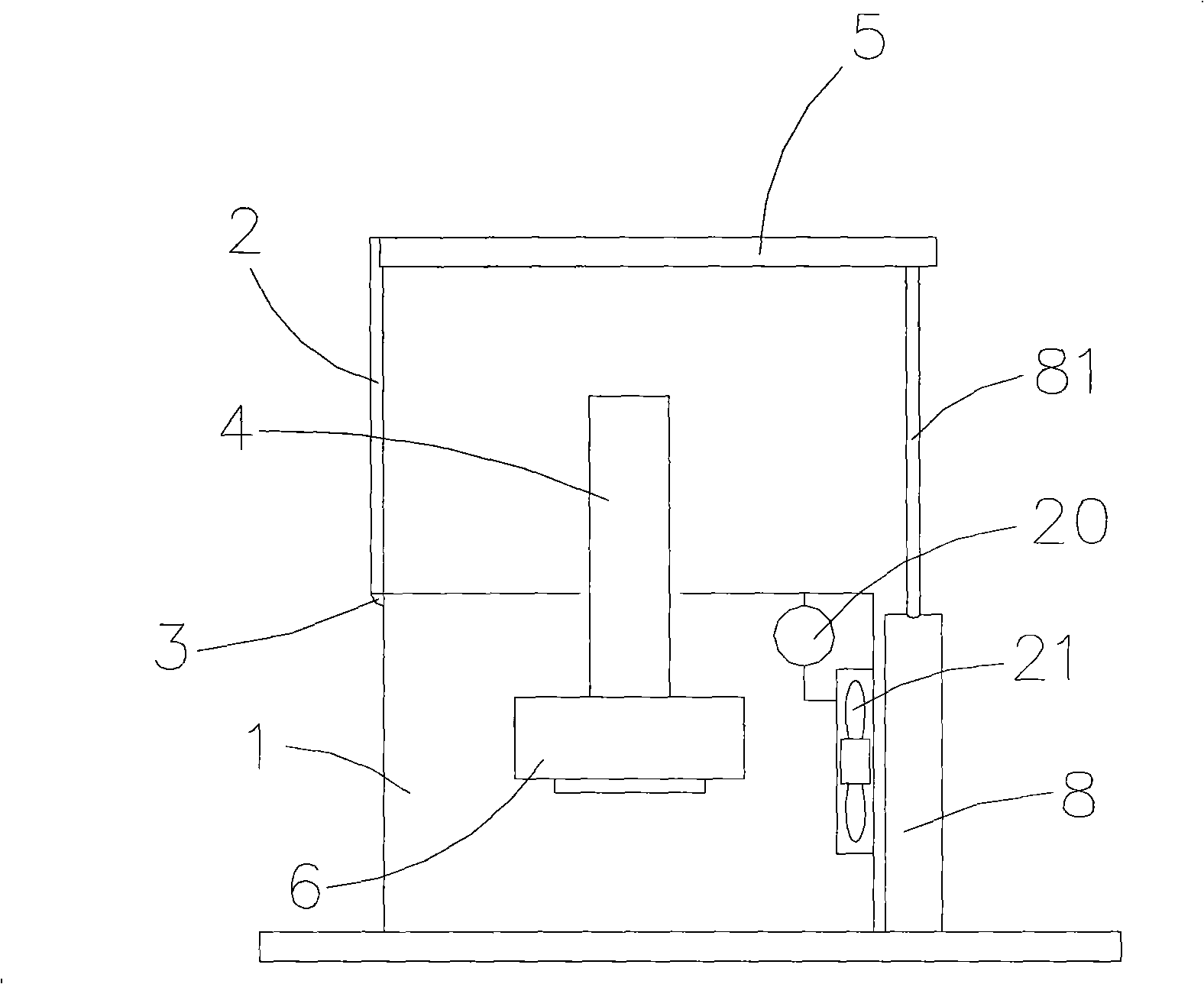

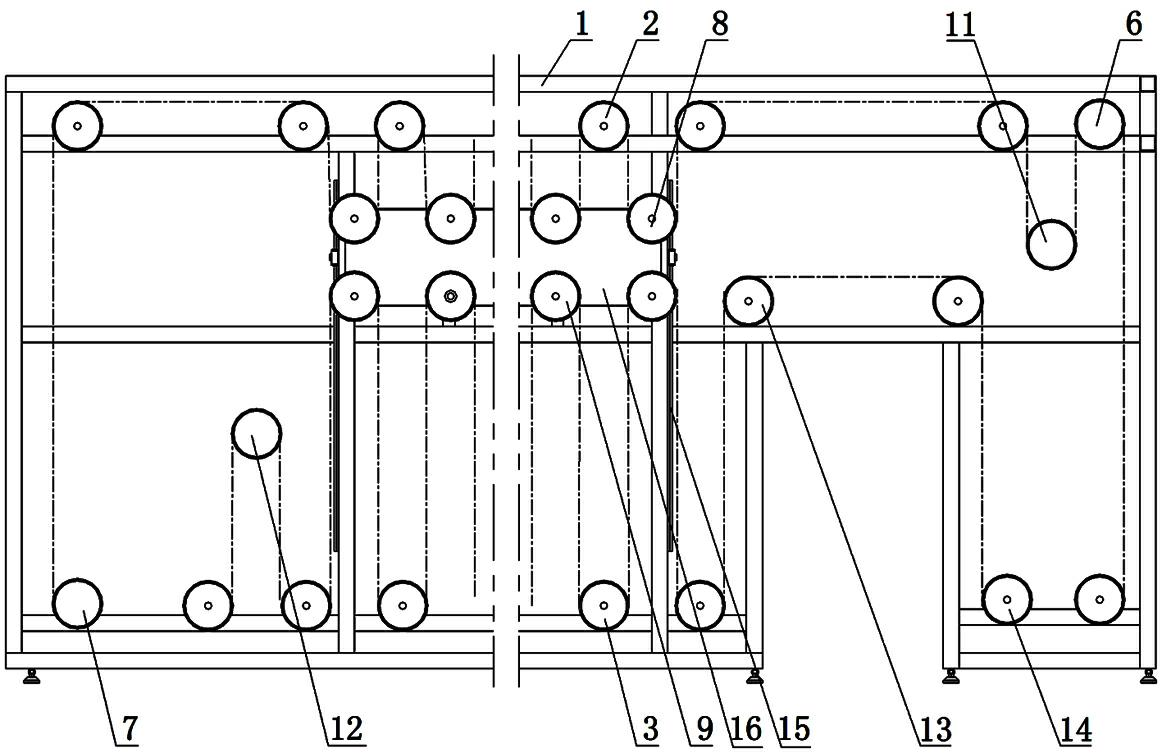

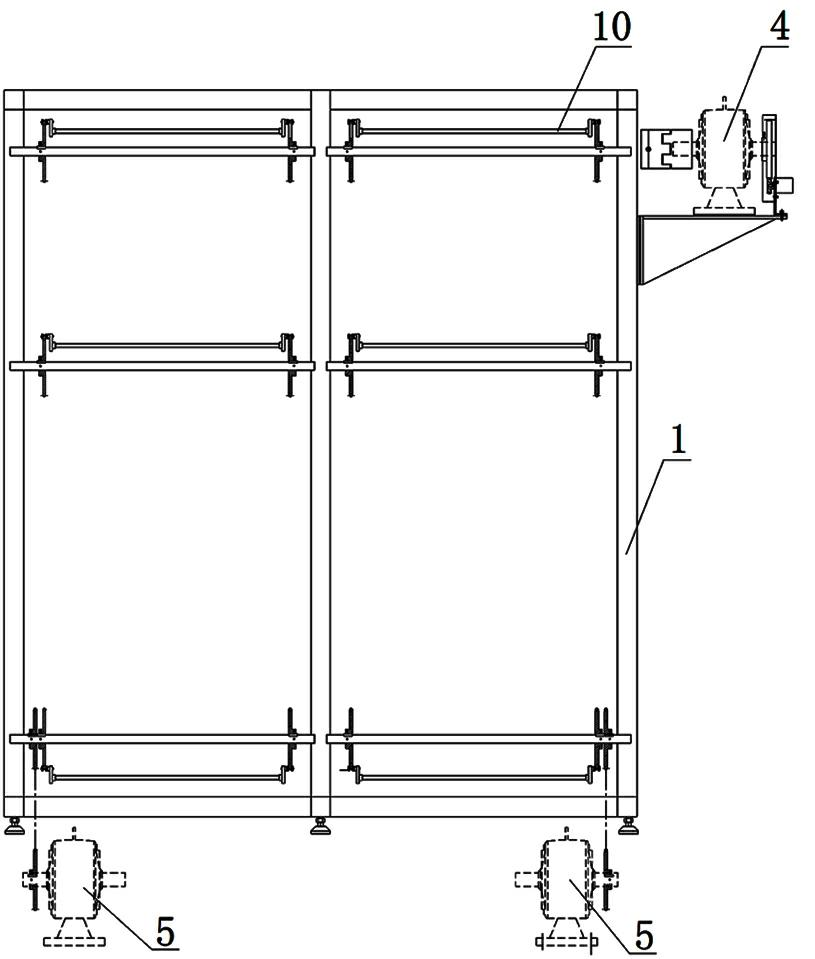

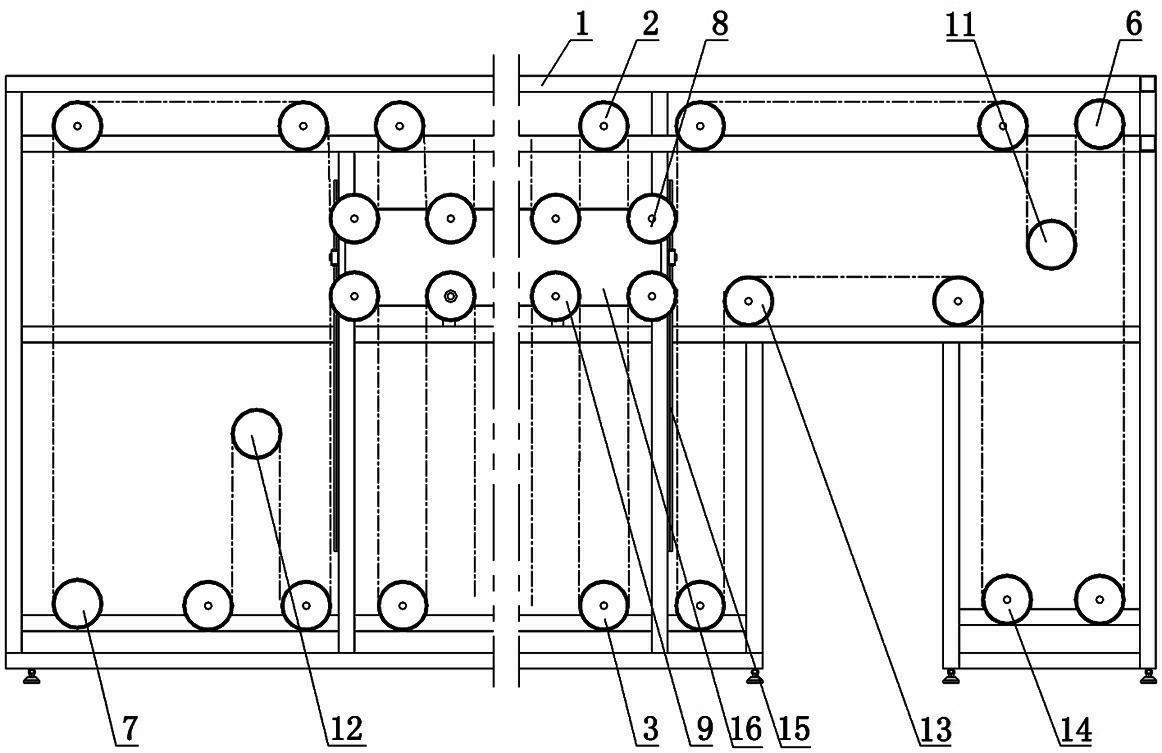

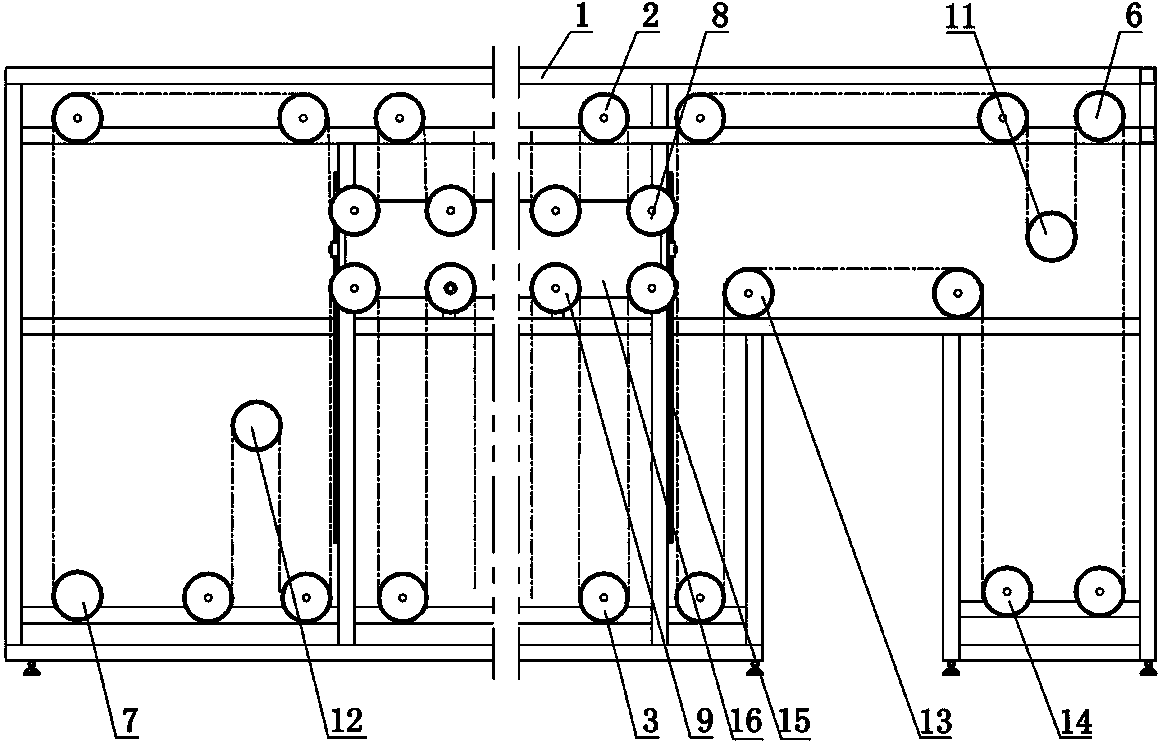

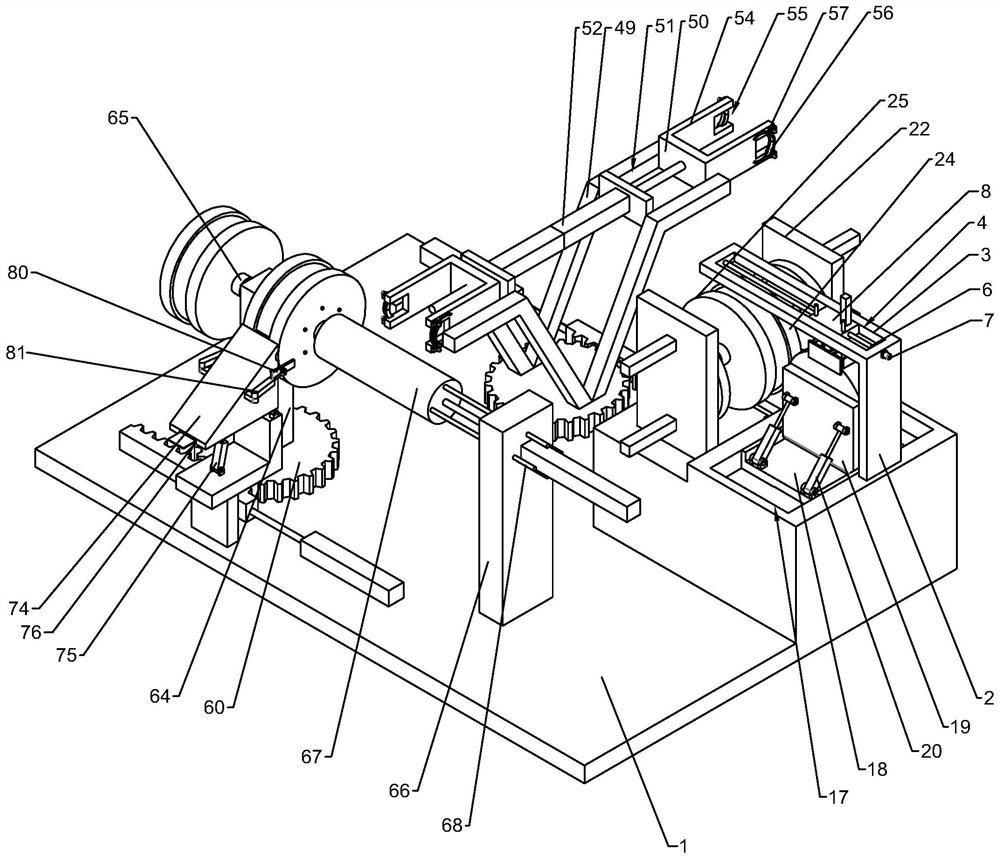

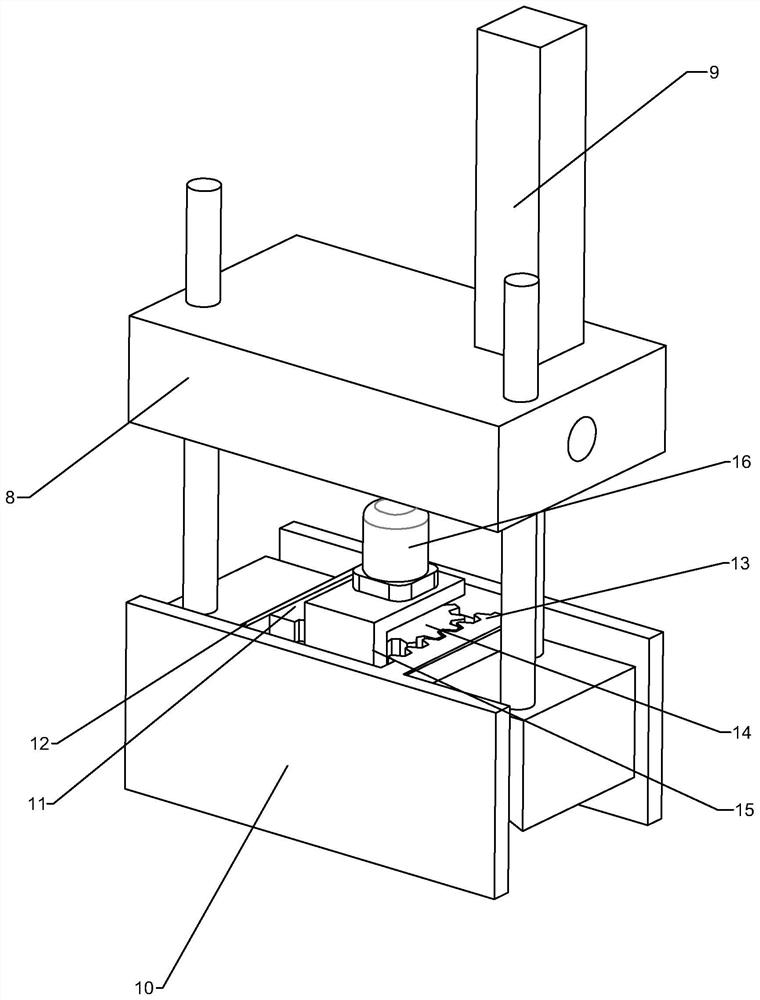

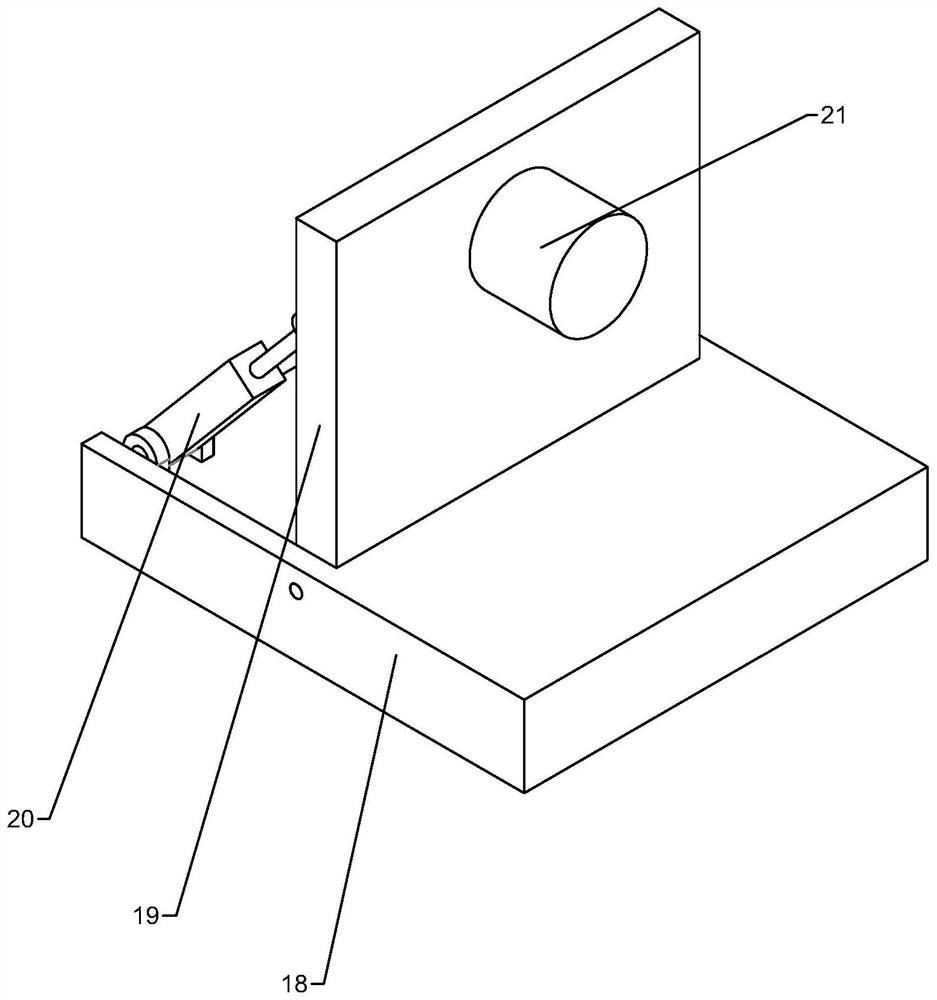

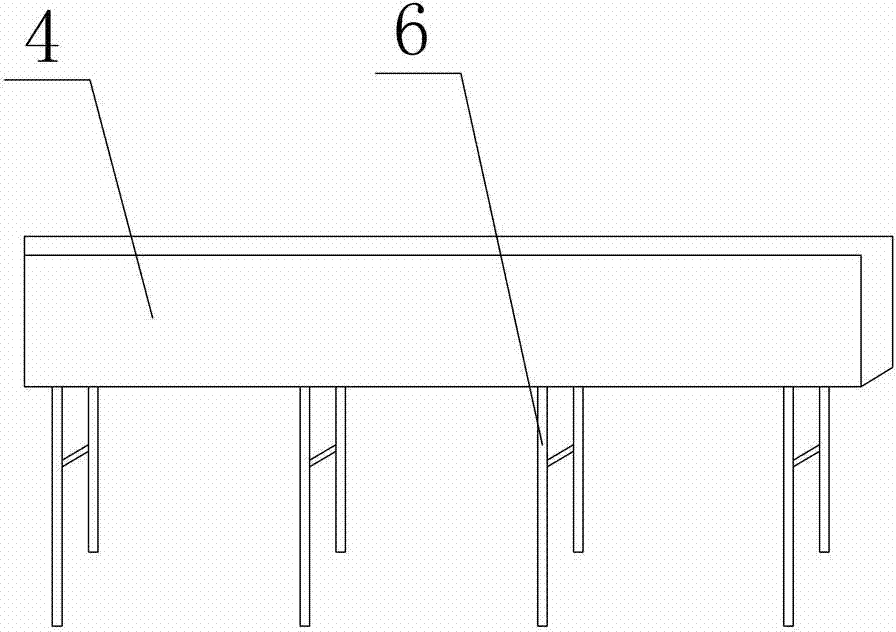

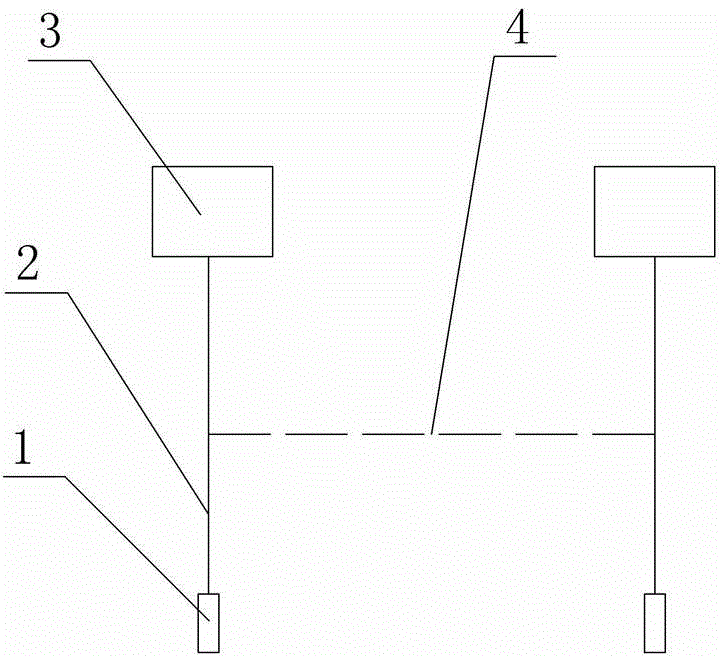

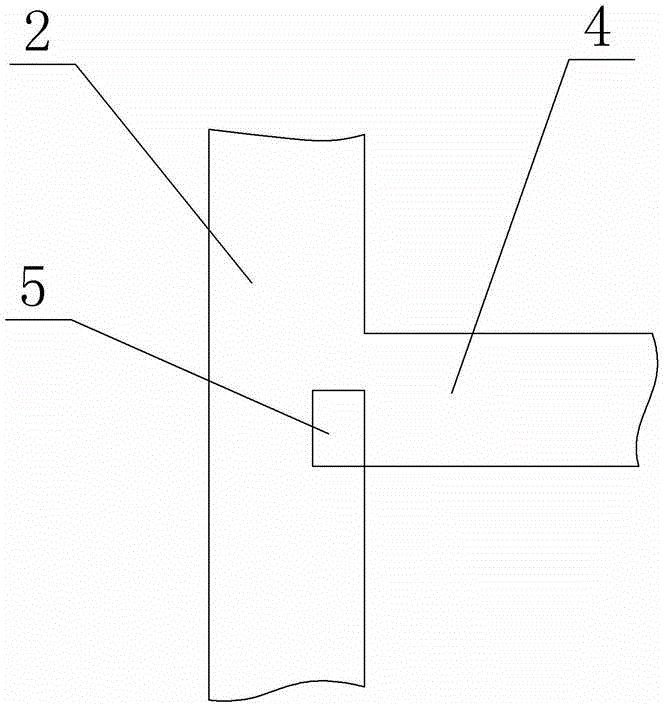

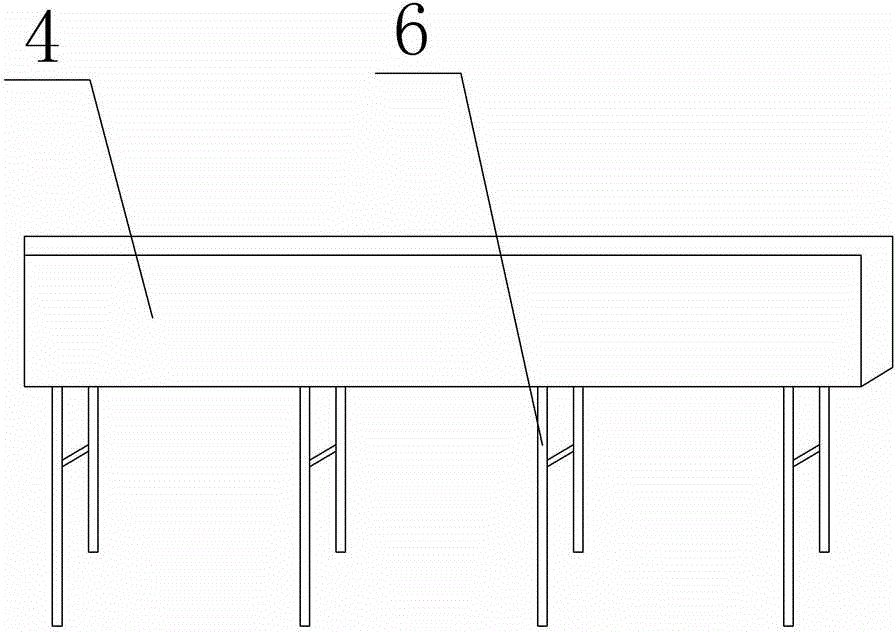

Noodle storage tower

The invention discloses a noodle storage tower, comprising a frame (1), an upper-row chain wheel group (2) and a lower-row chain wheel group (3) arranged on the frame (1), and further comprising an upper motor (4), a lower motor (5), an upper drive chain wheel group (6) connected with the upper motor (4), a lower drive chain wheel group (7) connected with the lower motor (5), and a movable chain wheel group arranged between the upper-row chain wheel group (2) and the lower-row chain wheel group (3), wherein a noodle storage mechanism (10) is arranged between chains at the both sides of the chain wheel group, a guide rail (15) and a slide plate (16) freely sliding along the guide rail (15) are further arranged on the frame (1), and the movable chain wheel group is fixed on the slide plate (16). The noodle storage tower disclosed by the invention has the advantages of being timely and sensitive in control, and rapid in response, thus ensuring no influence on production efficiency; the whole control process is high in the automation degree, accurate in control, and saving in labour and time; the noodle storage time is long, and manual processing on the noodle cakes is avoided, thus the sanitation of noodle pieces can be guaranteed; and the noodle storage tower is reliable in operation and convenient in maintenance.

Owner:成都中科经纬机械制造有限公司

Sleeve type component coiling classified circling device and method

InactiveCN107952835AImprove rolling effectAvoid bad phenomena such as pulling hairShaping toolsMetal chainsLarge headSmall head

The invention relates to a sleeve type component coiling classified circling device and method. The circling device is arranged on pipe coiling machine equipment and comprises a first classified circling die, a second classified circling die, a third classified circling die and a classified circling die fixing base, and after mechanisms are matched in a coordinative manner for coiling, a sleeve ispushed into the classified circling dies through circling nails to be subjected to circling work. After being arranged and combined from top to bottom, the three classified circling dies are arrangedin the classified circling die fixing base, the first classified circling die is located at the uppermost end, the second classified circling die is located at the middle position, and in addition, the third classified circling die is located on the bottommost layer. According to the sleeve type component coiling classified circling device and method, the work process is simple, operation is easy, later producing and maintaining are easy, the sleeve coiling effect is good, the bad phenomena of large-head end face and small-head end face galling and the like can be effectively avoided, the performance is stable, and the production efficiency is not influenced.

Owner:QINGDAO CHOHO IND CO LTD

Automobile lower fender apron with automatic silt-discharging function

The patent of the present invention discloses an automobile lower guard plate with the function of self-discharging silt, which belongs to the technical field of auto parts processing, and includes a plate body; There are drain holes; plate body reinforcement ribs are formed between the water tanks; the sediment discharge hole is located at the lower part of the plate body, and is located under the water tank; there are guard plate installation holes around the plate body; the edge of the plate body is provided with Up hem. The present invention can effectively guarantee the reasonable water drainage and sediment discharge of the guard plate body by opening the sediment discharge hole in the lower part of the plate body, and the sediment discharge hole is arranged under the water tank, which is simple and easy, and only uses the product structure Partial changes and the lowest cost to solve the problem of sediment clogging, production efficiency is not affected, no need to replace equipment, materials, tooling, etc., greatly reducing production costs, shortening the processing cycle, and improving production and processing efficiency.

Owner:SUZHOU ENGLEY AUTO PARTS CO LTD

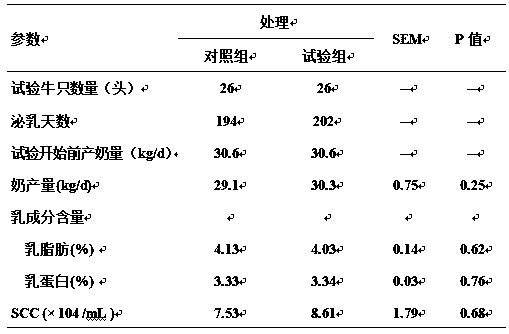

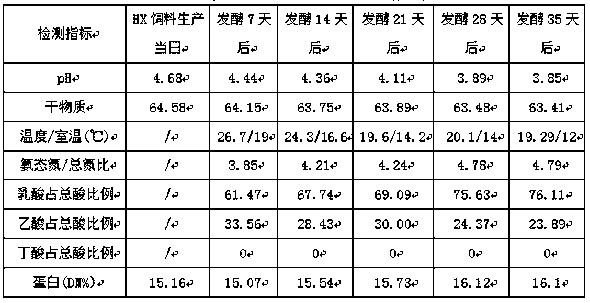

Fermented feed for lactating cows

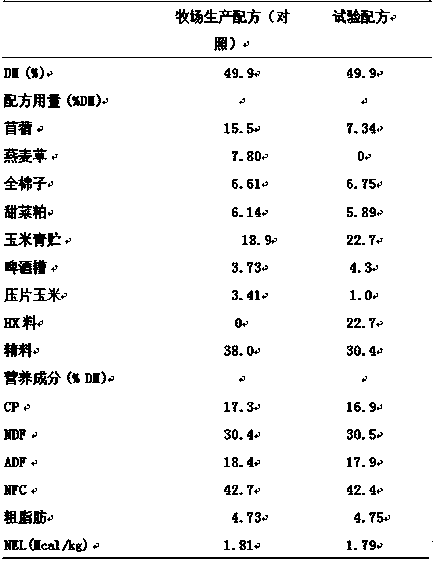

InactiveCN109393170AReduce usageReduce dependenceFood processingAnimal feeding stuffBiotechnologyPasture

The invention relates to fermented feed for lactating cows. The fermented feed is characterized by being prepared from fermentation substrates and a microbial inoculum by fermentation, wherein the mass ratio of the microbial inoculum to the fermentation substrates is (0.2-5):500000; the fermentation substrates comprise 3%-10% of alfalfa, 5%-15% of oat grass, 7%-35% of paddy rice straw, 1%-5% of molasses, 13%-30% of corn, 2%-8% of maize germ meal, 5%-15% of brewer's grains, 5%-15% of bean meal, 1%-3% of a premix and 10%-20% of water, and the content is in mass percent; and the total water content of the fermentation substrates is 35%-40%. The fermented feed can substitute for partial alfalfa and oat grass in pasture TMR, and cannot affect the production performance of primiparous cows and multiparous cows; and as a raw material for TMR production in cow breeding in China, the fermented feed can effectively reduce the consumption of the alfalfa and the oat grass used on the lactating cows in pasture production, and reduce dependence of cow production in China on the alfalfa and the oat grass.

Owner:宁波天赋饲料科技有限公司

Noodle storage tower

Owner:成都中科经纬机械制造有限公司

Novel flying saw machine

The invention discloses a novel flying saw machine, and relates to the technical field of steel production equipment. The machine comprises an operation table, two transportation brackets are fixed onthe operation table, a plurality of fixed tables and cutting tables are respectively arranged on the two transportation brackets in a sliding manner, cutting brackets are fixed on the cutting tables,and gas cutting guns are arranged in the cutting brackets in a sliding manner. Connecting columns are fixed to the sides of the cutting brackets, supporting frames are fixed to the fixed tables, limiting plates are fixed to the sides, away from the fixed tables, of the supporting frames, connecting grooves are formed in the limiting plates in a penetrating mode, and locking devices for locking steel pipes are fixed to the fixed tables. The locking devices comprise two locking rods arranged on the cutting tables in a sliding mode and cutting plates arranged on the fixed tables in a sliding mode. The novel flying saw machine is high in safety coefficient, stable in cutting quality and convenient to overhaul.

Owner:天津市天元昌昊农业设施有限公司

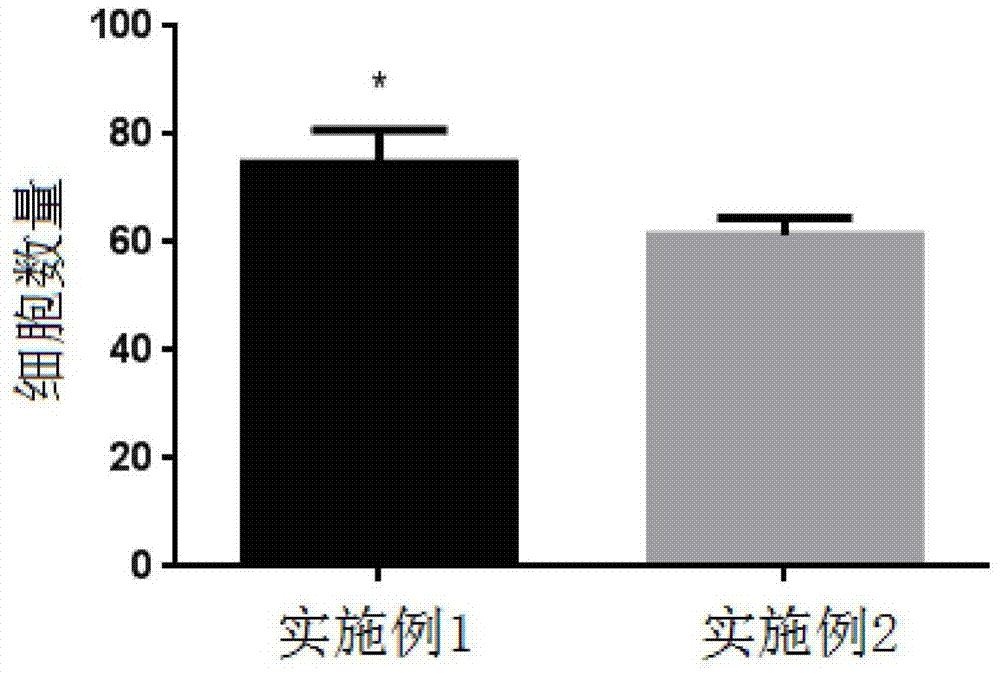

A kind of synbiotic feed additive and its application

InactiveCN104397324BReduce usageHeat resistantAnimal feeding stuffAccessory food factorsFood additiveSynbiotics

Owner:广东新南都饲料科技有限公司 +2

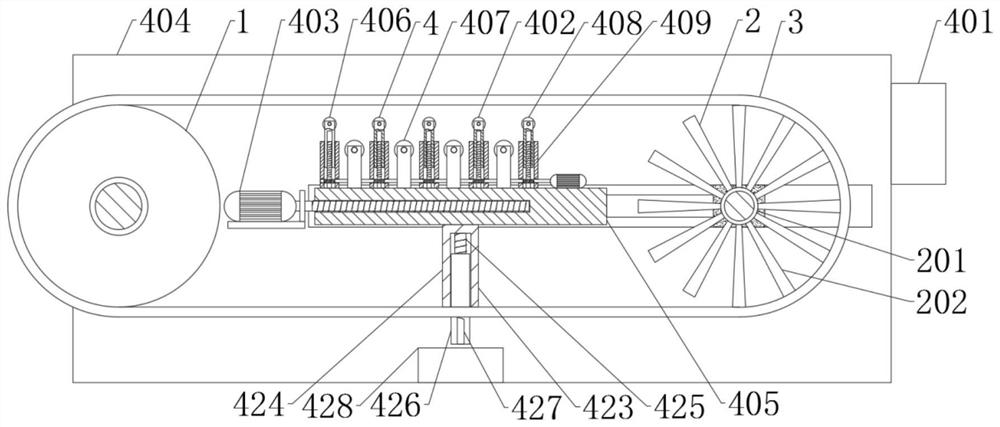

Anti-deflection belt conveyor

The embodiment of the invention discloses an anti-deflection belt conveyor. The conveyor comprises a transmission roller, a rotating roller and a conveying belt arranged between the transmission roller and the rotating roller. The conveyor is characterized in that materials are conveyed from the rotating roller to the transmission roller, the rotating roller comprises a rotating part and a plurality of supporting parts arranged on the outer wall of the rotating part in an annular array for supporting the conveying belt, and wedge-shaped convex parts are arranged between each two adjacent supporting parts. According to the conveyor, vertical support plates arranged in an annular array are used to turn the conveying belt, desulfurized gypsum adhering to the conveying belt falls between the two vertical support plates to avoid the situation that squeezing action generates between the rotating roller and the conveying belt, leading to accumulation of the desulfurized gypsum after squeezingon the surface of the rotating roller, resulting in deviation, material leakage and damage to the conveying belt, normal operation of production orders is ensured, and the production efficiency of gypsum boards is not affected.

Owner:BEIJING NEW BUILDING MATERIALS PLC

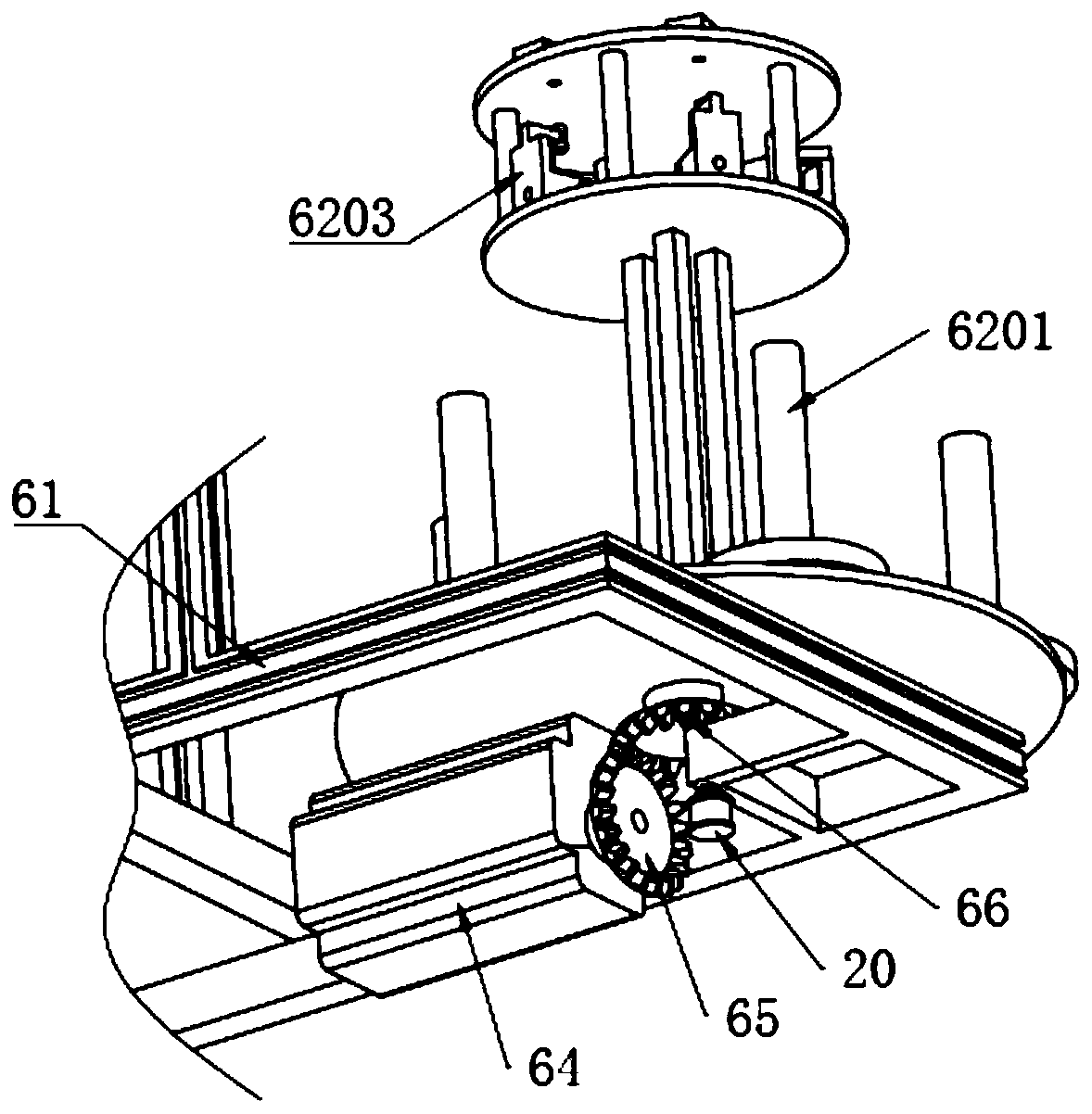

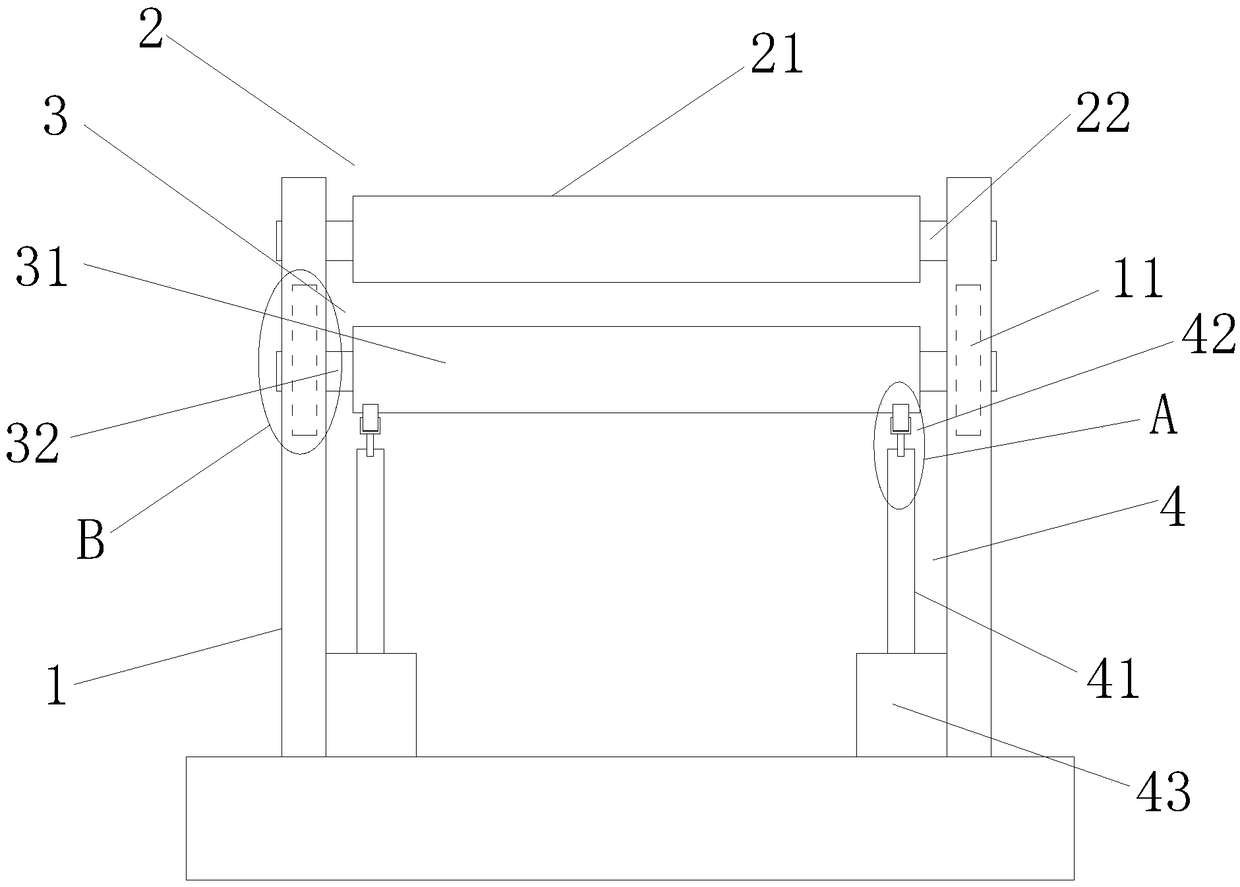

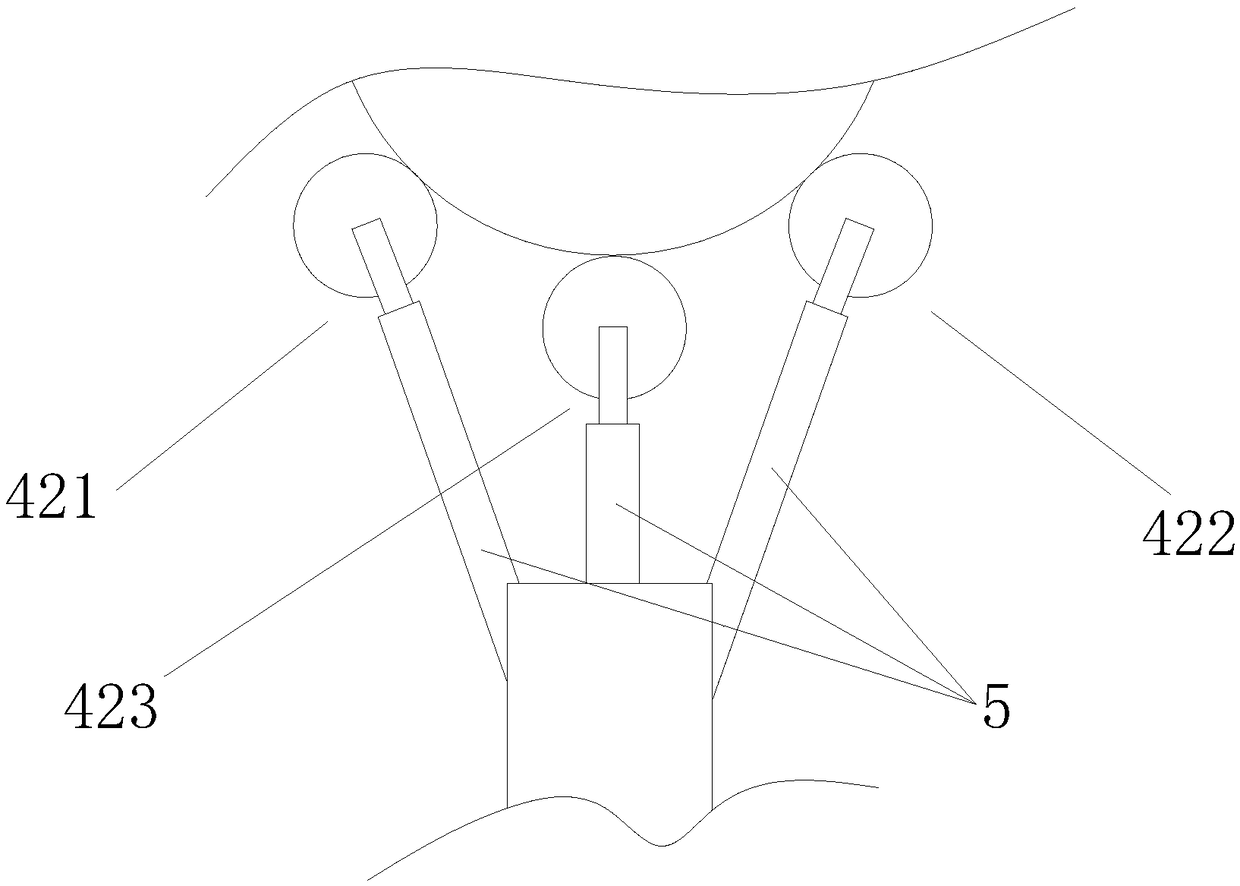

Strip steel uncoiling machine

PendingCN112692100AProductivity is not affectedReduce the difficulty of operationEngineeringStrip steel

The invention discloses a strip steel uncoiling machine, and relates to the technical field of strip steel production equipment. The strip steel uncoiling machine comprises an operation table, the operation table is provided with a conveying rotating disc in a rotating mode, a feeding support is fixed to the conveying rotating disc, in addition, feeding tables are arranged on the two sides of the feeding support in a sliding mode, feeding plates are fixedly arranged on the two sides of the feeding tables, feeding cavities are formed in the feeding plates, moreover, feeding ports communicating with the feeding cavities are formed in one sides of the feeding plates, a driving support is arranged on one side of the operation table, an uncoiling roller is arranged on the driving support in a rotating mode, a supporting frame is fixed to one side of the operation table, two supporting rods are fixed in the supporting frame, control devices are arranged on the two supporting rods in a sliding mode, each control device comprises a main clamping plate and an auxiliary clamping plate, and the main clamping plates and the auxiliary clamping plates are matched with the supporting rods on the corresponding sides in a sliding mode correspondingly. The strip steel uncoiling machine has the advantages that the labor consumption can be reduced, stable uncoiling of a strip steel coil can be guaranteed, and potential safety hazards of equipment can be reduced.

Owner:天津市天元昌昊农业设施有限公司

A kind of low chloropropanol microbial grease and preparation method thereof

ActiveCN107418982BInhibitory activityReduce contentMicroorganism based processesFermentationBiotechnologyMicrobial oil

The present invention provides a microbial oil containing low chloropropanol and a preparation method thereof, comprising: adding lipase inhibitor to a fermentation liquid of microbial fermentation, then extracting, refining and deodorizing to reduce the content of glycidyl ester and / or chloropropanol in the obtained microbial oil. The lipase inhibitor is capable of inhibiting the activity of lipases in microbial cells in the fermentation liquid.

Owner:CABIO BIOTECH WUHAN CO LTD

An anti-deviation belt conveyor

The embodiment of the present invention discloses an anti-deflection belt conveyor, which includes a driving roller, a rotating roller, and a transmission belt arranged between the driving roller and the rotating roller. The driving roller conveys materials, and the rotating roller includes a rotating part and a plurality of supporting parts arranged in an annular array on the outer wall of the rotating part for supporting the conveyor belt. Wedge-shaped protrusions are arranged between two adjacent supporting parts. At the beginning, the present invention utilizes the vertical support plates arranged in a circular array to turn the conveyor belt, and the desulfurized gypsum adhering to the conveyor belt falls between the two vertical support plates to avoid extrusion between the steering roller and the conveyor belt The effect causes the extruded desulfurized gypsum to accumulate on the surface of the turning drum, causing deviation, material leakage and damage to the conveyor belt, so as to ensure the normal production order and the production efficiency of the gypsum board will not be affected.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Multi-furnace casting method for aluminum ingot and chute assembly and casting equipment for implementing the method

InactiveCN103551530BScientific recyclingProductivity is not affectedPig casting plantsMolten metal conveying equipmentsProduction lineMetallurgy

The invention discloses a multi-furnace casting method for an aluminum ingot, and a chute assembly and casting equipment for implementing the method. The chute assembly comprises more than two main chutes connected between tap holes of corresponding mixing furnaces and casting production lines respectively, wherein the main chutes are sequentially connected through branch chutes; flow division structures are arranged at joints of the main chutes and the branch chutes; adjusting devices for adjusting the slopes of the branch chutes to change the flowing direction of diffluent molten aluminum in the branch chutes are connected to the branch chutes. Molten aluminum flowing out from any mixing furnace can flow to any casting production line, so that influence on the production efficiency of the aluminum ingot is eliminated; more importantly, the molten aluminum can continuously flow into any mixing furnace, so that aluminum block waste caused by casting interruption can be reduced; in addition, normal maintenance operation over other unused mixing furnaces can be reasonably and effectively scheduled, so that the mixing furnaces can be scientifically recycled, and the production cost is lowered.

Owner:ZHENGZHOU FAXIANG ALUMINUM IND

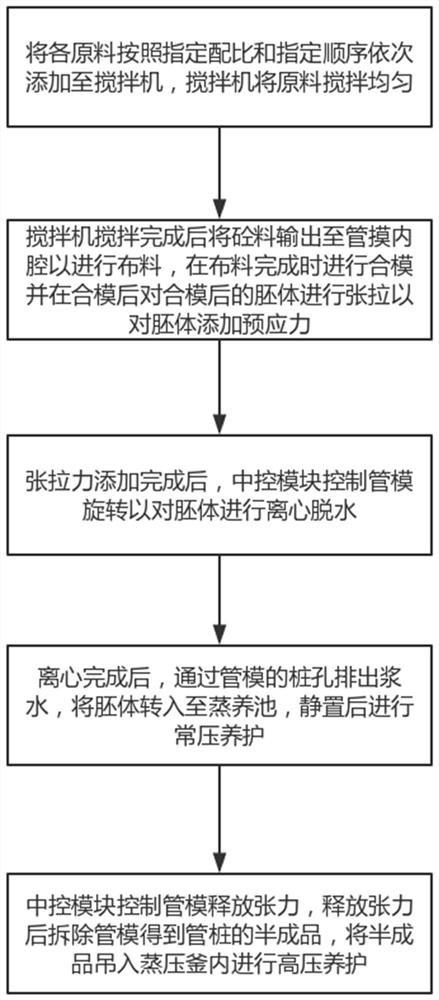

Preparation technology of tube pile

ActiveCN111805724AImprove production efficiencyLow costAuxillary shaping apparatusCement mixing apparatusPre stressCentrifugation

The invention relates to a preparation technology of a tube pile. The technology comprises the following steps: stirring raw materials uniformly to form a concrete material; outputting the concrete material to an inner cavity of a tube mold for material arrangement, and adding pre-stress to a blank body after completion of material arrangement; rotating the mold to realize centrifugation and de-watering of the blank body; rotating the blank body into a steam curing pool for constant-pressure curing; and hoisting a semi-finished product into a still kettle for high-pressure curing. According tothe preparation technology, a central control module is added in a system using the technology, the raw materials with different proportions are selected, and each parameter in each process can be set to be a corresponding preset value according to the proportions of the raw materials, so that the technology can realize targeted tube pile preparation according to the raw materials of the designated proportions and thus preparation efficiency of the technology is effectively increased.

Owner:广东鸿业管桩有限公司

Preparation method of mineral insulated cable porcelain column

The invention discloses a preparation method of a mineral insulated cable porcelain column. According to the method, cellulose with 600-800 polymerization degree is used as a raw material and then subjected to alkalization and etherification under certain technological conditions to obtain an adhesion agent with 50-80mPa*s viscosity. The adhesion agent has appropriate viscosities so that the calcination temperature of the porcelain column can be reduced to 750 DEG C in the later period of porcelain column manufacturing, and energy consumption is greatly reduced; and the adhesion agent can be dissolved in water at normal temperatures, and energy consumption for dissolving the adhesion agent is saved. The preparation method is used for preparing magnesium oxide of the porcelain column, the energy consumption during magnesium oxide producing is reduced, and the production costs of the magnesium oxide is around 2 / 3 of those of electric smelting magnesium oxide. According to the magnesium oxide porcelain column prepared by the preparation method, the density of the final porcelain column is 2.0g / cm<3>, and the weight of the porcelain column can be reduced by 10%-15% without influencing the production rate of the porcelain column. According to the preparation method of the mineral insulated cable porcelain column, the technical problem during a production process of the mineral insulated cable porcelain column is solved, the energy consumption is greatly reduced, and the production costs of the mineral insulated cable porcelain column are reduced.

Owner:SHANGHAI TONNOR MATERIAL SCI

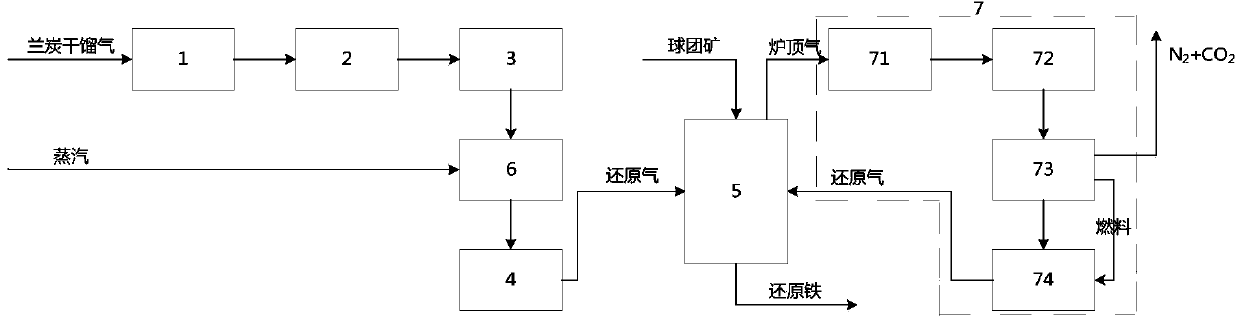

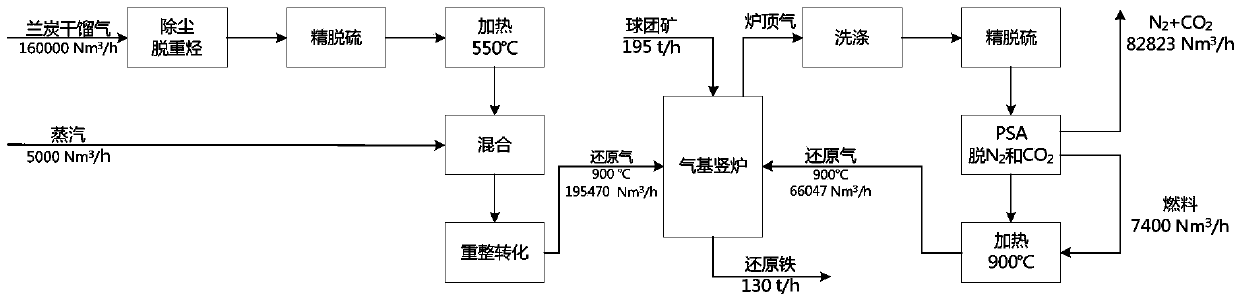

A method and device for producing reduced iron using gas-to-synthesis gas

ActiveCN103834760BImprove use valueImprove efficiencyShaft furnaceGas emission reductionSyngasFlammability limit

The invention provides a method and a device for producing reduced iron by using synthesis gas prepared from gas. The method comprises the following steps: (1) purifying the gas, mixing the purified gas with steam and / or natural gas so as to form a gas mixture which deviates from an explosion limit; (2) converting the gas mixture and oxygen-containing gas or CO2 in a converter so as to generate the synthesis gas containing H2, CO and N2, specifically, the conversion of the gas mixture and the oxygen-containing gas in the converter refers to the partial burning of the gas mixture and the oxygen-containing gas at a nozzle outlet of the converter, and controlling flame temperature to 900-1700 DEG C during burning; and controlling the temperature of the synthesis gas at an outlet of the converter to 850 DEG C-1300 DEG C and the pressure of the synthesis gas to 0.1-0.5Mpa; and (3) enabling the synthesis gas containing H2, CO and N2 serving as all or partial reducing gas to enter a gas-base shaft furnace so as to reduce ferric oxide, so that the reduced ion is generated. The method and the device have the advantages that the utilization value of the gas is increased, and the utilization efficiency of the gas is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Multi-furnace casting method for aluminum ingot, and chute assembly and casting equipment for implementing method

InactiveCN103551530AScientific recyclingProductivity is not affectedPig casting plantsMolten metal conveying equipmentsProduction lineMetallurgy

The invention discloses a multi-furnace casting method for an aluminum ingot, and a chute assembly and casting equipment for implementing the method. The chute assembly comprises more than two main chutes connected between tap holes of corresponding mixing furnaces and casting production lines respectively, wherein the main chutes are sequentially connected through branch chutes; flow division structures are arranged at joints of the main chutes and the branch chutes; adjusting devices for adjusting the slopes of the branch chutes to change the flowing direction of diffluent molten aluminum in the branch chutes are connected to the branch chutes. Molten aluminum flowing out from any mixing furnace can flow to any casting production line, so that influence on the production efficiency of the aluminum ingot is eliminated; more importantly, the molten aluminum can continuously flow into any mixing furnace, so that aluminum block waste caused by casting interruption can be reduced; in addition, normal maintenance operation over other unused mixing furnaces can be reasonably and effectively scheduled, so that the mixing furnaces can be scientifically recycled, and the production cost is lowered.

Owner:ZHENGZHOU FAXIANG ALUMINUM IND

Preparation method of magnesium oxide for insulated cable knob insulator, magnesium oxide and application of magnesium oxide

Owner:SHANGHAI TONNOR MATERIAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com