Strip steel uncoiling machine

An uncoiler and strip steel technology, which is applied in the field of strip steel production equipment, can solve problems such as complicated uncoiler loading operation, impact on workshop production efficiency, and waste of manpower and time, so as to achieve unaffected production efficiency, reduce labor consumption, and save energy. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be clearly and completely described below in conjunction with the embodiments.

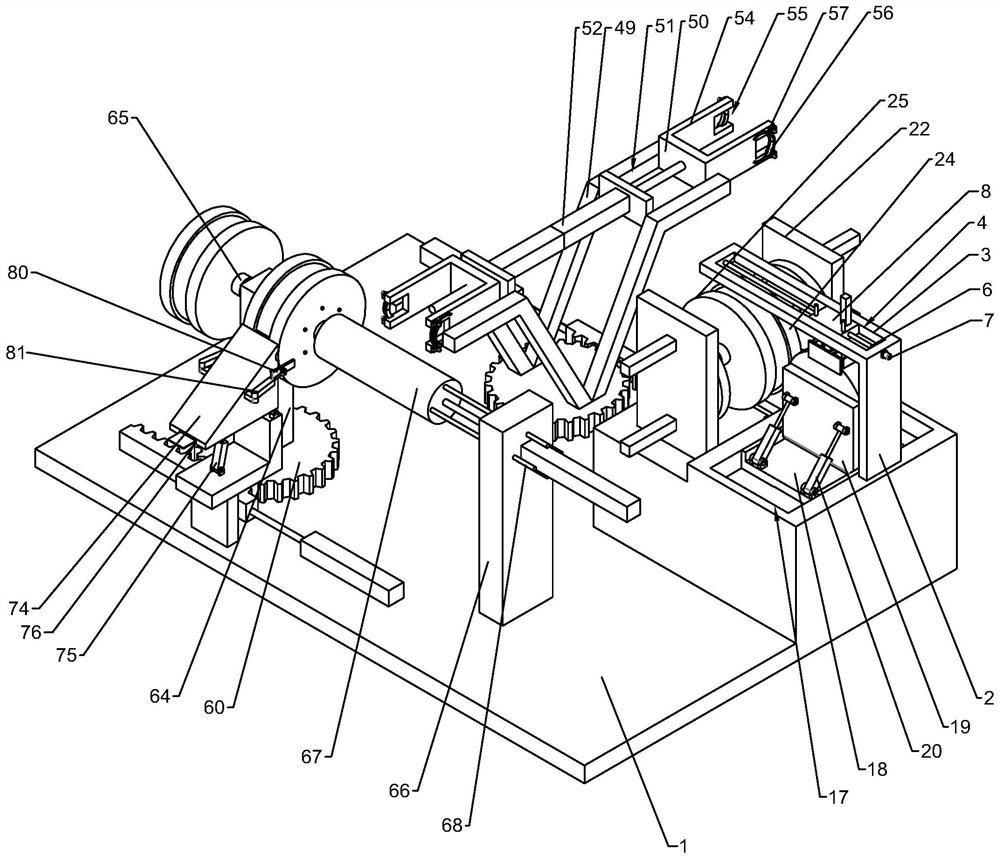

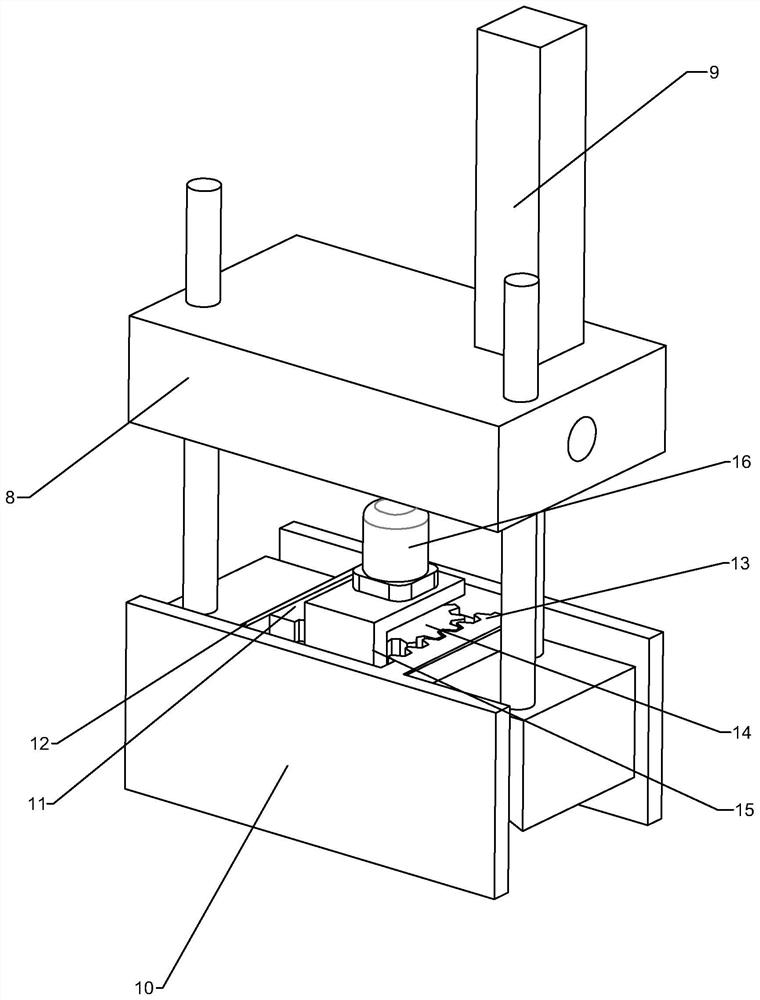

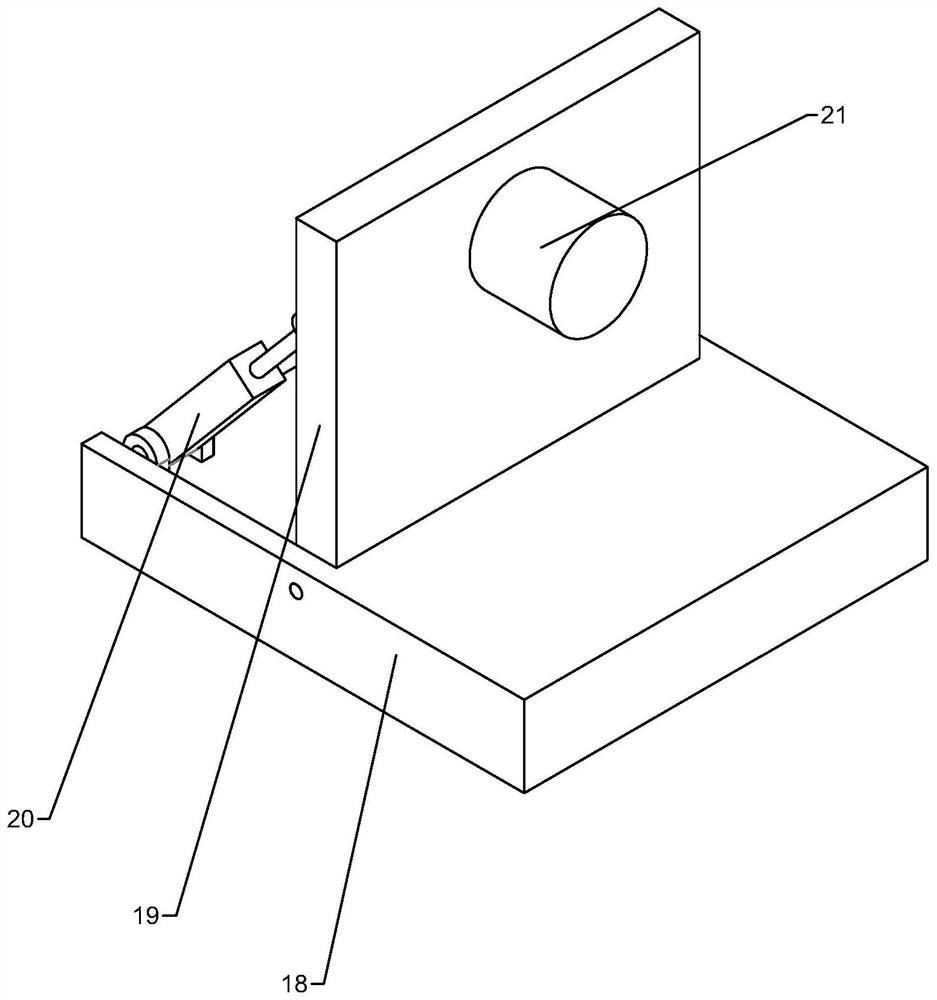

[0038] See attached figure 1 And attached figure 2 , a strip steel uncoiler, comprising an operating table 1, the operating table 1 is in a rectangular structure, a transport bracket 2 is vertically fixed on one side of the operating table 1, and a transport cross bar 3 is fixed on the side of the transport bracket 2 away from the operating table 1, The transport horizontal plate 81 is provided with a transport groove 4, and a control plate 5 is provided for sliding in the transport groove 4, and a transport screw 6 is arranged for rotation in the transport groove 4, and the transport screw 6 runs through the control plate 5 and is threaded with it. Cooperate, and the transport horizontal plate 81 side is fixed with the transport motor 7, the output shaft of the transport motor 7 is coaxially fixed with the transport screw rod 6, the lower surface of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com