Process for reclaiming Pd from waste Pd-C catalyst

A technology of waste catalyst and catalyst is applied in the efficient recovery of palladium, and in the economic field, it can solve the problems of low palladium yield, environmental protection problems, complicated processes, etc., and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0030] Except in Example 1, the raw material incineration process does not add additive calcium carbonate, all the other are operated under the conditions of Example 1, and the experimental results are shown in Table 1.

example 3

[0032] Except that in Example 1, when the palladium salt was dissolved, deionized water was used instead of hydrochloric acid with an acidity of 2 mol / L, and the rest were operated under the conditions of Example 1. The experimental results are shown in Table 1.

[0033]

Example

palladium in palladium salt solution

Content (mg)

Quantity (mg)

Palladium Liquid Phase Recovery

Rate(%)

Palladium Total Recovery

Rate(%)

example 1

372

366

99.2

97.6

Example 2

350

345

93.3

92.0

Example 3

366

363

97.6

96.8

[0034] Note: 50g raw material contains palladium 375mg

[0035] Find out from table 1 data, the adding of additive makes the content of palladium in the palladium salt solution obviously improve; Replace the hydrochloric acid that acidity is 2mol / L with deionized water, the leaching rate of palladium declines to som...

example 4 to example 7

[0037] Using the method of Example 1, the palladium salt solution prepared was tested under different electrolysis conditions, and the test results are shown in Table 2.

[0038] Example

Cathode potential V

Electrolysis time h

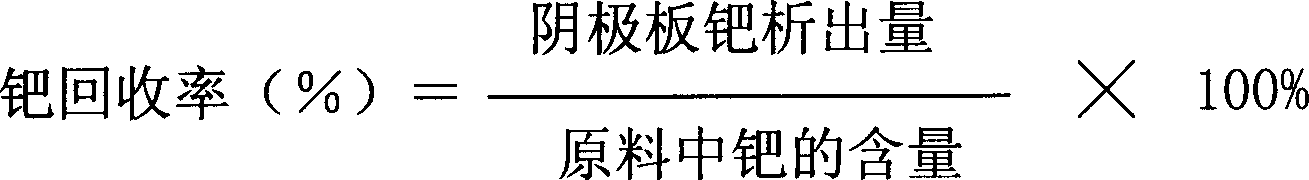

Palladium yield %

Palladium purity %

Example 4

-1.13

5

98.5%

99.9

Example 5

-1.13

4

98.3%

99.9

Example 6

-1.19

4

98.6%

99.9

Example 7

-1.25

4

98.61%

96.2

[0039] Note: Palladium yield refers to the precipitation rate of palladium before and after electrolysis

[0040] Table 2 data can find out that the prolongation of electrolysis time and the raising of cathode reduction potential can improve the reduction precipitation rate of rhodium powder, but when electric potential is brought up to more than-1.20V, the raising of rhodium powder precipitation rate is not very obvious, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com