Heat conducting oil vapour generator

A technology of steam generator and heat transfer oil, which is applied in the steam generation method using heat carrier, etc. It can solve the problems of high water content in steam, affecting steam quality, and low heat exchange efficiency, so as to achieve high heat exchange efficiency and sufficient heat exchange Good effect, good steam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

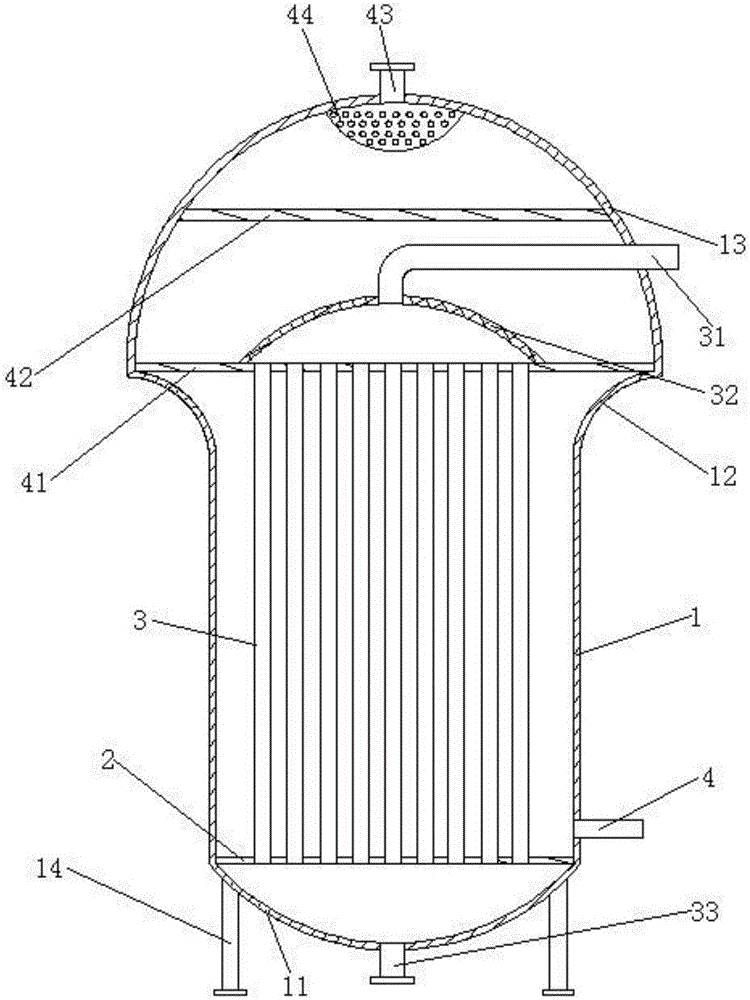

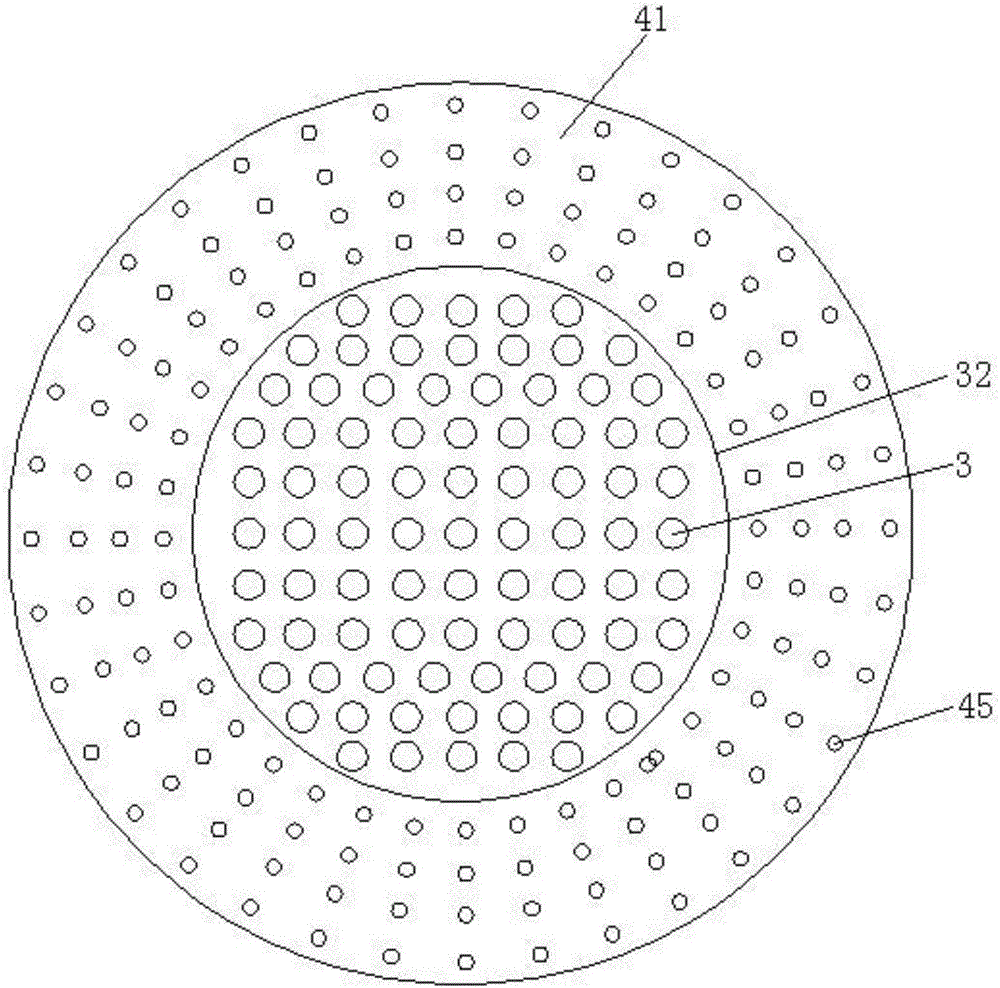

[0012] Such as figure 1 , figure 2 As shown, a heat-conducting oil steam generator includes a hollow cylindrical main cylinder 1 with openings at both ends, the upper end of the main cylinder 1 is connected with an upper cylinder 13 through a middle cylinder 12, and the lower end of the main cylinder 1 Connected with a lower cylinder 11, the middle cylinder 12 is an arc-shaped cylinder whose diameter gradually increases from bottom to top, and the arc-shaped cross-section is protruding from the side where the heat-conducting oil pipe 3 is located, and can be exchanged with the heat-conducting oil pipe 3. The motion of the heat-formed steam provides a curved route guide to speed up the steam passing through the equalizing holes 45 .

[0013] The upper cylinder 13 is a hollow hemispherical structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com