A device for controlling flue gas emission of diesel generator sets with fine water mist

A technology of diesel generator set and high-pressure water mist, which is applied in the direction of exhaust device, electric control of exhaust treatment device, noise reduction device, etc. It can solve the problems of poor cooling and smoke elimination effect, low safety, waste, etc., and achieve large Initial kinetic energy and diffuseness, sufficient heat transfer effect, and the effect of avoiding waste of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

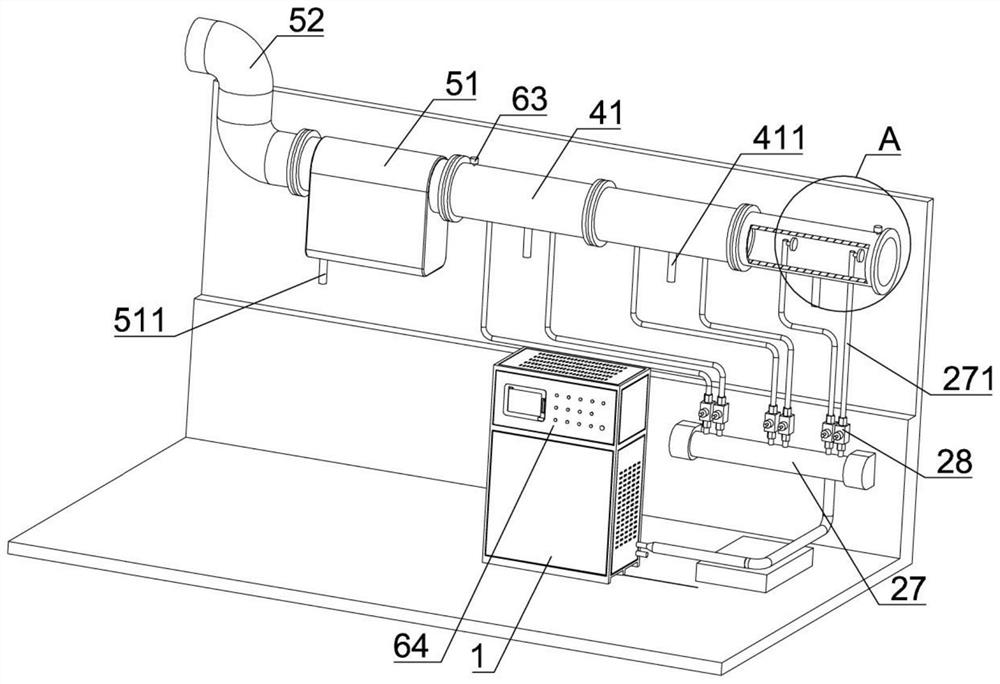

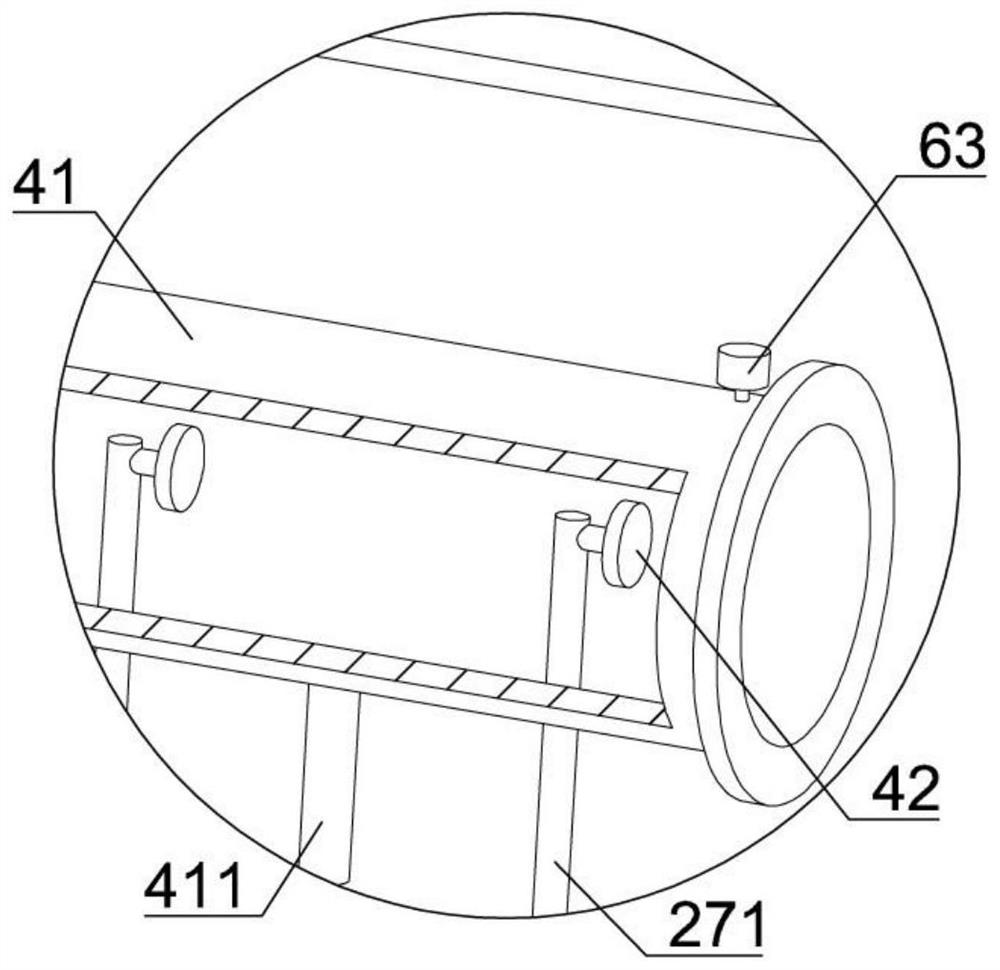

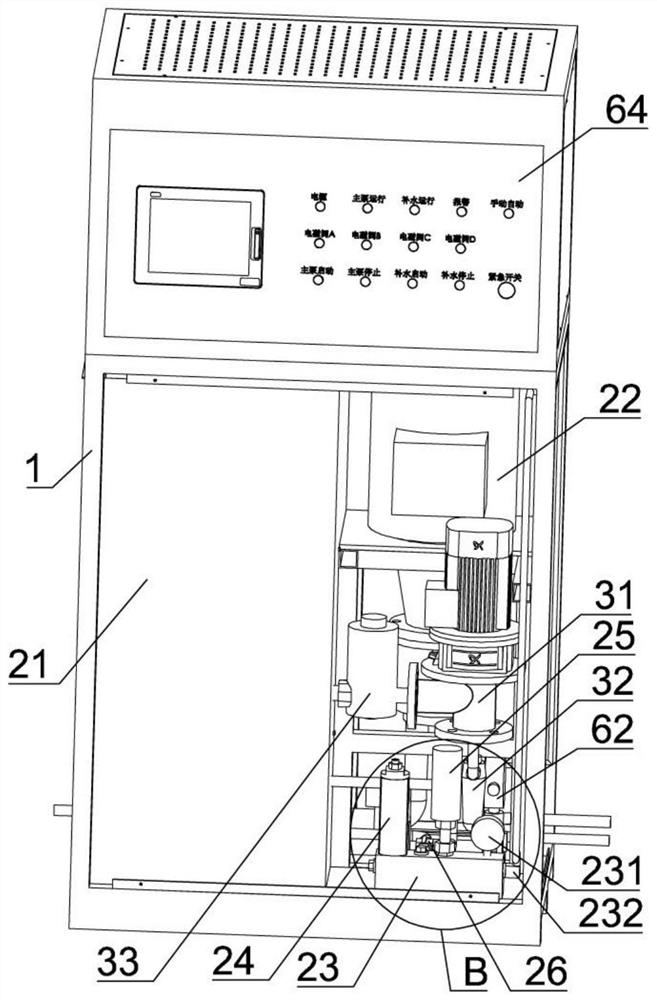

[0036] Such as Figure 1-Figure 6As shown, a device for controlling flue gas emission of a diesel unit with fine water mist according to the present invention includes a cabinet body 1 and a high-pressure water mist smoke elimination and cooling device. Inside the cabinet body 1, there is a replenishment water intake pipeline, and the water replenishment intake pipeline The water supply filter 32 is fixedly connected, the water supply filter 32 outlet end is fixedly connected with the water supply pump 31, the water supply pump 31 outlet end is fixedly connected with the fine filter 33, the fine filter 33 is fixedly connected with the water storage tank 21, and the top of the water storage tank 21 is provided with a liquid position sensor, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com