Cement-based capillary crystalline material and preparation method thereof

A permeable crystallization, cement-based technology, applied in the field of cement-based permeable crystalline materials and their preparation, can solve the problems of poor seepage resistance of the overall structure, not repaired in time, affecting the life and quality of the overall structure, and promote the hydration reaction. , Improve the durability, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

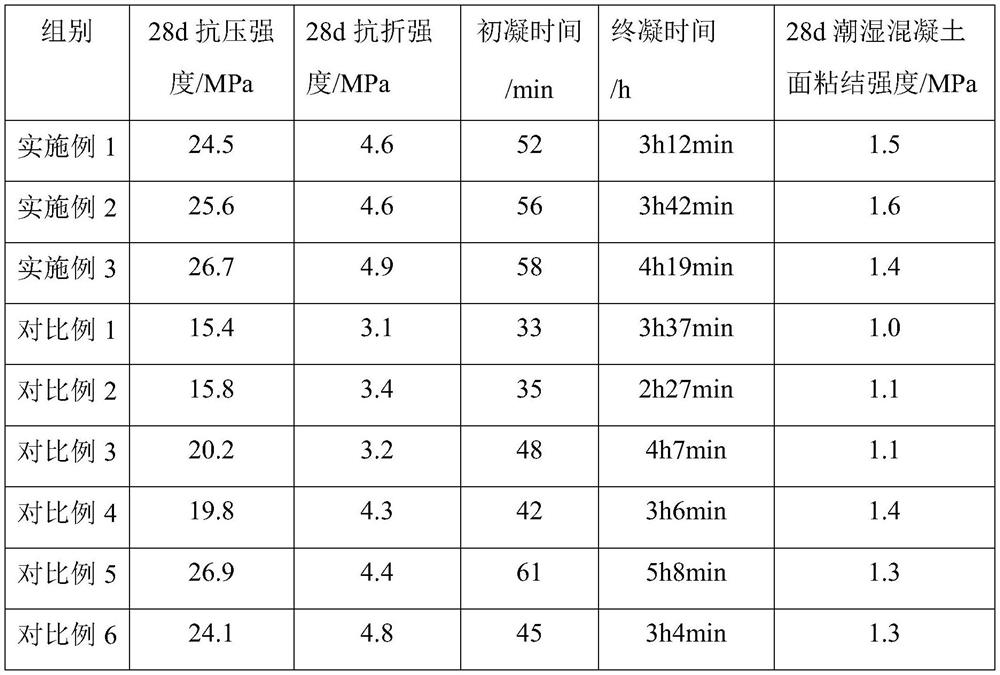

[0022] The cement-based permeable crystalline material provided in this embodiment includes the following raw materials in parts by weight: 50 parts of Portland cement, 30 parts of quartz sand, 5 parts of calcium hydrogen phosphate, 2 parts of sodium silicate, and 6 parts of hydrated silicic acid Calcium nanocrystal nucleus suspension, 3 parts of double-ended amino polyethylene glycol.

[0023] Wherein, the particles in the cement whose particle size is less than 5 μm account for 16% of the weight of the cement, thereby increasing the hydration speed of the cement. The quartz sand adopts high-purity quartz sand, and the quartz sand is ground to a specific surface area greater than 420m 2 / kg;

[0024] The preparation method of the cement-based permeable crystalline material in this embodiment comprises the following steps:

[0025] 1) Mix and stir cement and quartz sand evenly to obtain powder, and stir for 5 minutes;

Embodiment 2

[0028] The cement-based permeable crystalline material provided in this embodiment includes the following raw materials in parts by weight: 50 parts of Portland cement, 30 parts of quartz sand, 5 parts of calcium hydrogen phosphate, 2 parts of sodium silicate, and 9 parts of hydrated silicic acid Calcium nanocrystal nucleus suspension, 3 parts of double-ended amino polyethylene glycol.

[0029] Wherein, the particles in the cement whose particle size is less than 5 μm account for 16% of the weight of the cement, thereby increasing the hydration speed of the cement. The quartz sand adopts high-purity quartz sand, and the quartz sand is ground to a specific surface area greater than 420m 2 / kg;

[0030] The preparation method of the cement-based permeable crystalline material in this embodiment comprises the following steps:

[0031] 1) Mix and stir cement and quartz sand evenly to obtain powder, and stir for 5 minutes;

[0032] 2) Add calcium hydrogen phosphate, sodium silic...

Embodiment 3

[0034] The cement-based permeable crystalline material provided in this embodiment includes the following raw materials in parts by weight: 50 parts of Portland cement, 30 parts of quartz sand, 5 parts of calcium hydrogen phosphate, 2 parts of sodium silicate, 12 parts of hydrated silicic acid Calcium nanocrystal nucleus suspension, 3 parts of double-ended amino polyethylene glycol.

[0035] Wherein, the particles in the cement whose particle size is less than 5 μm account for 16% of the weight of the cement, thereby increasing the hydration speed of the cement. The quartz sand adopts high-purity quartz sand, and the quartz sand is ground to a specific surface area greater than 420m 2 / kg;

[0036] The preparation method of the cement-based permeable crystalline material in this embodiment comprises the following steps:

[0037] 1) Mix and stir cement and quartz sand evenly to obtain powder, and stir for 5 minutes;

[0038] 2) Add calcium hydrogen phosphate, sodium silicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com