Anti-mud additive suitable for machine-made sand concrete and compounding method thereof

A technology of concrete and machine-made sand, which is applied in the field of building materials and concrete to achieve the effects of non-destructive product quality, high fluidity, and strong defoaming power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

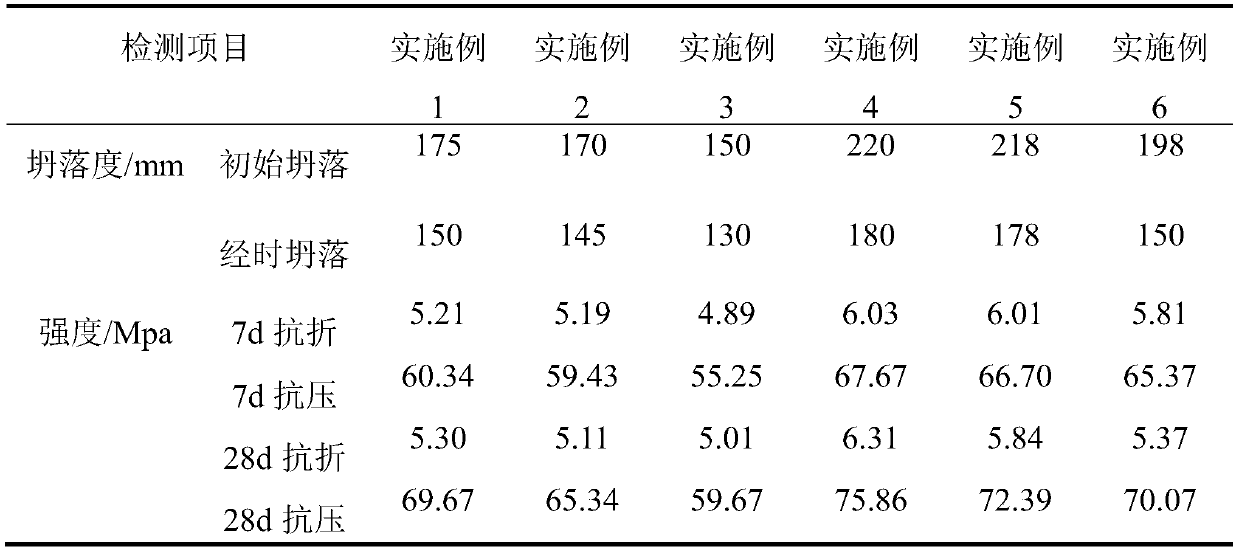

Examples

Embodiment 1

[0033] The viscosity-reducing polycarboxylic acid water-reducing agent is prepared by the following method: preparing an aqueous solution of methacrylic acid-polyethylene glycol methyl ether ester, adding it to the reaction kettle and heating, and then adding the mass concentration after heating to 40-60°C The 42% ammonium persulfate aqueous solution is used as the initiator for the stirring reaction. After stirring evenly, the A solution and the B solution are added dropwise to the reaction kettle at the same time. The dropping time is 4-8h, and the stirring is continued while the addition is complete. After heat preservation for 1.5-2.5h, after adding a sodium hydroxide aqueous solution with a mass concentration of 31%, and controlling the pH value between 7-9, the viscosity-reducing polycarboxylic acid water reducer is obtained. The solid content of the water agent is 40-50%, and the water reduction rate is ≥28%. Among them, the A solution is an aqueous solution formed by mix...

Embodiment 2

[0036] An anti-mud admixture suitable for machine-made sand concrete. The anti-mud admixture includes a lignosulfonate water reducer, the viscosity-reducing polycarboxylic acid water reducer prepared in Example 1, a defoamer and water, The lignosulfonate water-reducing agent is sodium lignosulfonate water-reducing agent, the solid content of the sodium lignosulfonate water-reducing agent is 30-40%, the water-reducing rate is 8-14%, and the defoaming agent is Silicone defoamer; water is deionized water, based on parts by weight, with the following ratios: 45 parts of sodium lignosulfonate water reducer, 34.8 parts of viscosity reducing polycarboxylic acid water reducer, and 0.2 parts of silicone defoamer Parts, 20 parts deionized water. The components of the anti-mud admixture were stirred at 60°C for 7 hours, and then heated for 2.5 hours, and then evenly mixed into the machine-made sand concrete. The weight of the anti-mud admixture was the amount of the cementitious material ...

Embodiment 3

[0038] An anti-mud admixture suitable for machine-made sand concrete. The anti-mud admixture includes a lignosulfonate water reducer, the viscosity-reducing polycarboxylic acid water reducer prepared in Example 1, a defoamer and water, The lignosulfonate water-reducing agent is sodium lignosulfonate water-reducing agent, the solid content of the sodium lignosulfonate water-reducing agent is 30-40%, the water-reducing rate is 8-14%, and the defoaming agent is Organic silicon defoaming agent; water is deionized water, based on parts by weight, with the following ratios: 50 parts of sodium lignosulfonate water reducing agent, 20 parts of viscosity reducing polycarboxylic acid water reducing agent, and silicone defoaming agent 0.2 Parts, 29.8 parts deionized water. Stir the components of the anti-mud admixture at 50°C for 6 hours, then heat for 2 hours and mix them evenly into the machine-made sand concrete. The weight of the anti-mud admixture is the weight of the cementitious mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com