Adhesion sheet and preparation method thereof, and copper clad laminate using adhesion sheet

A technology for copper clad laminates and adhesive sheets, applied in the field of copper clad laminates, can solve the problems of poor fluidity, poor heat resistance, and high manufacturing costs, and achieve the effects of reducing costs, low dielectric loss, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

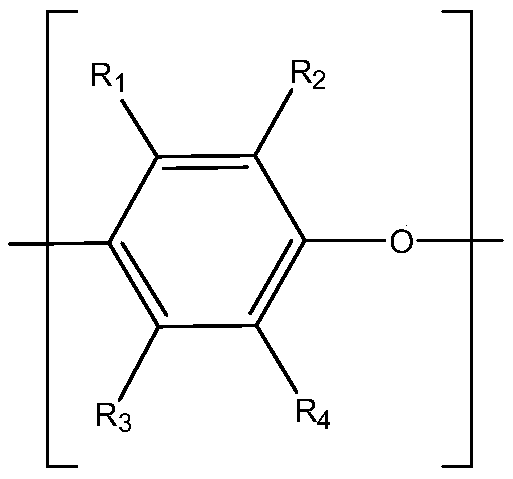

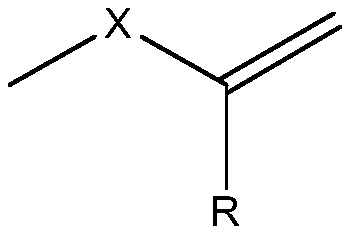

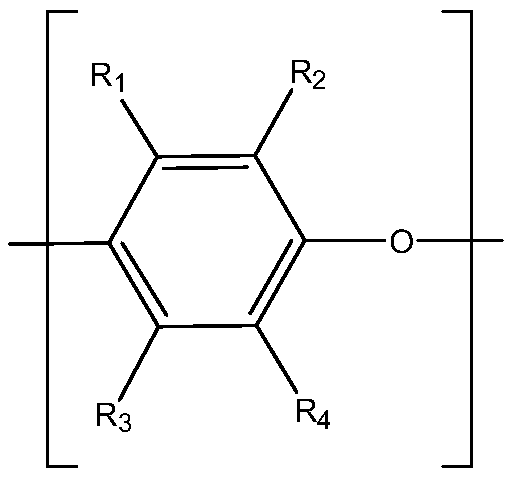

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of an adhesive sheet, specifically comprising the following steps:

[0049] Step S1, weighing the following components according to the parts by mass: 25-65 parts of matrix resin, 20-60 parts of fiber reinforcement, 10-40 parts of filler and 0-15 parts of flame retardant;

[0050]In this step, the types of the matrix resin, fiber reinforcement, filler and flame retardant are the same as those used in the above-mentioned adhesive sheet, and will not be repeated here.

[0051] Step S2, adding the matrix resin, filler and flame retardant into an appropriate solvent, and mixing uniformly to form a glue;

[0052] In this step, the solvent used is determined according to the types of the matrix resin, filler and flame retardant. Mixing can be carried out at a certain temperature, accompanied by stirring, which is conducive to uniform mixing.

[0053] Step S3, immersing the fiber reinforcement in the glue;

[0054] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com