Method for manufacturing color filter, color filter substrate and color filter

A technology for a color filter substrate and a manufacturing method, which is applied to the photoplate-making process, instruments, optical filters, etc. The effect of uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

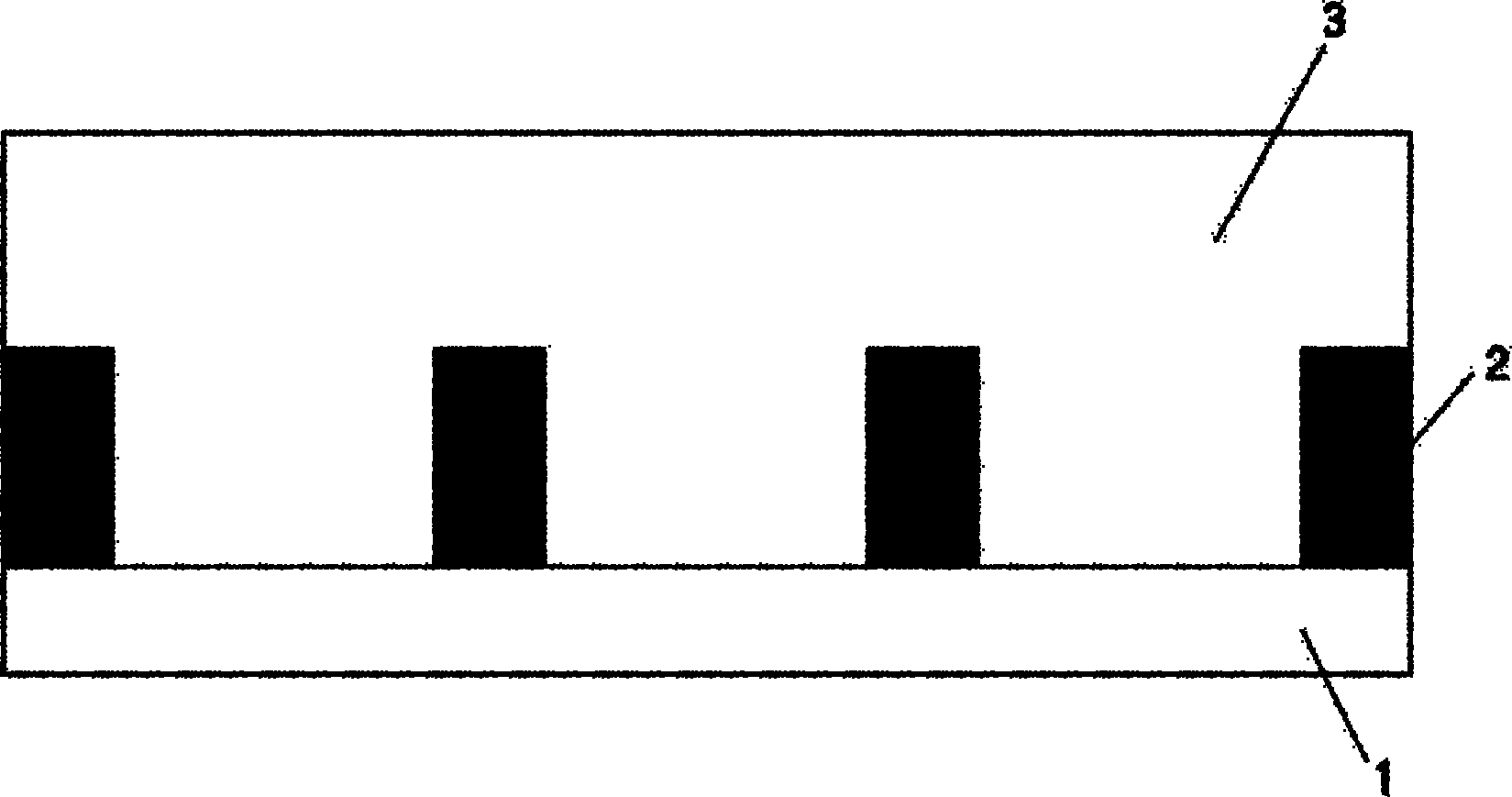

[0072] Example 1 (Preparation of a color filter substrate having partition walls formed on a metallic chromium black matrix)

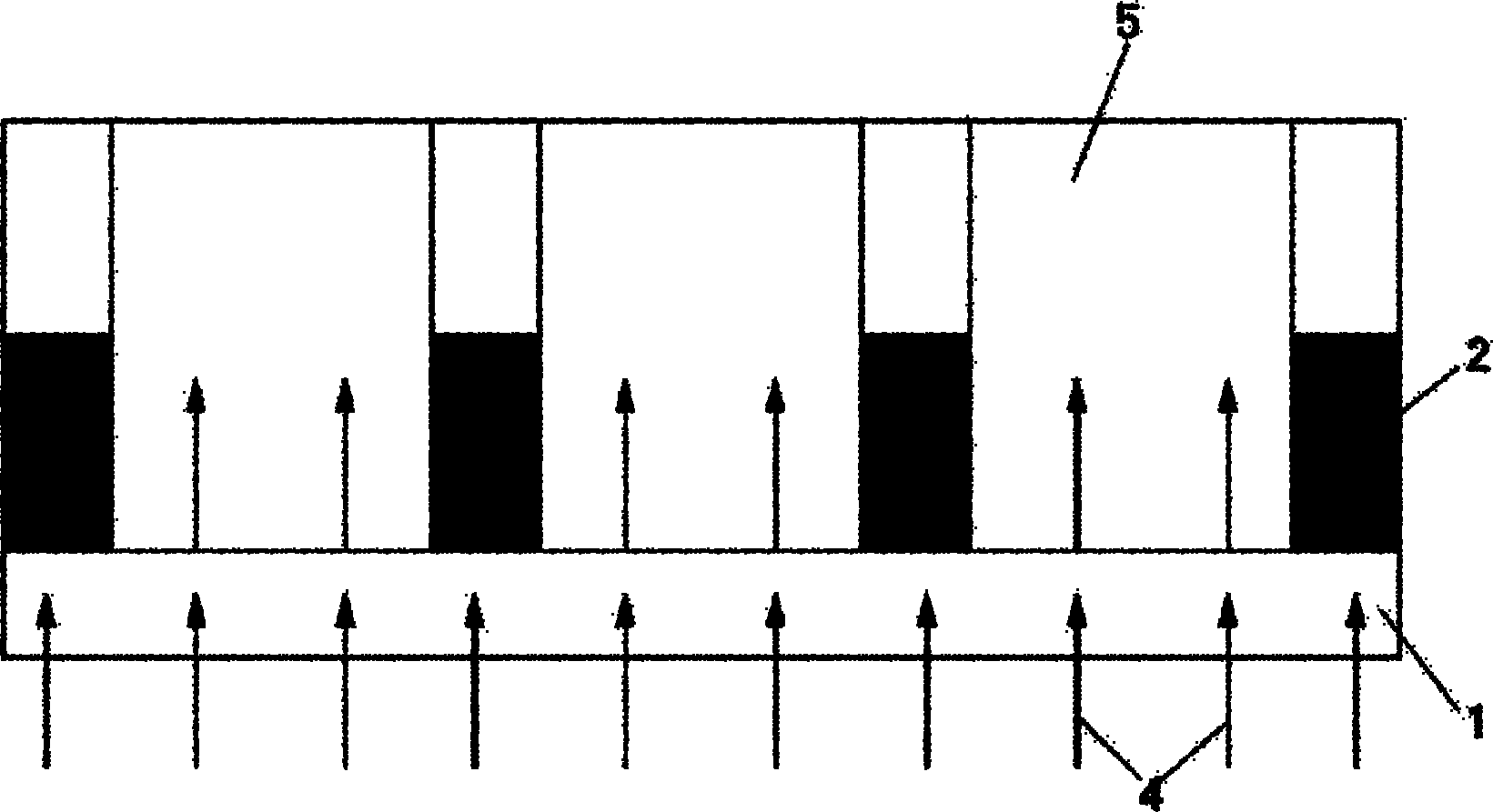

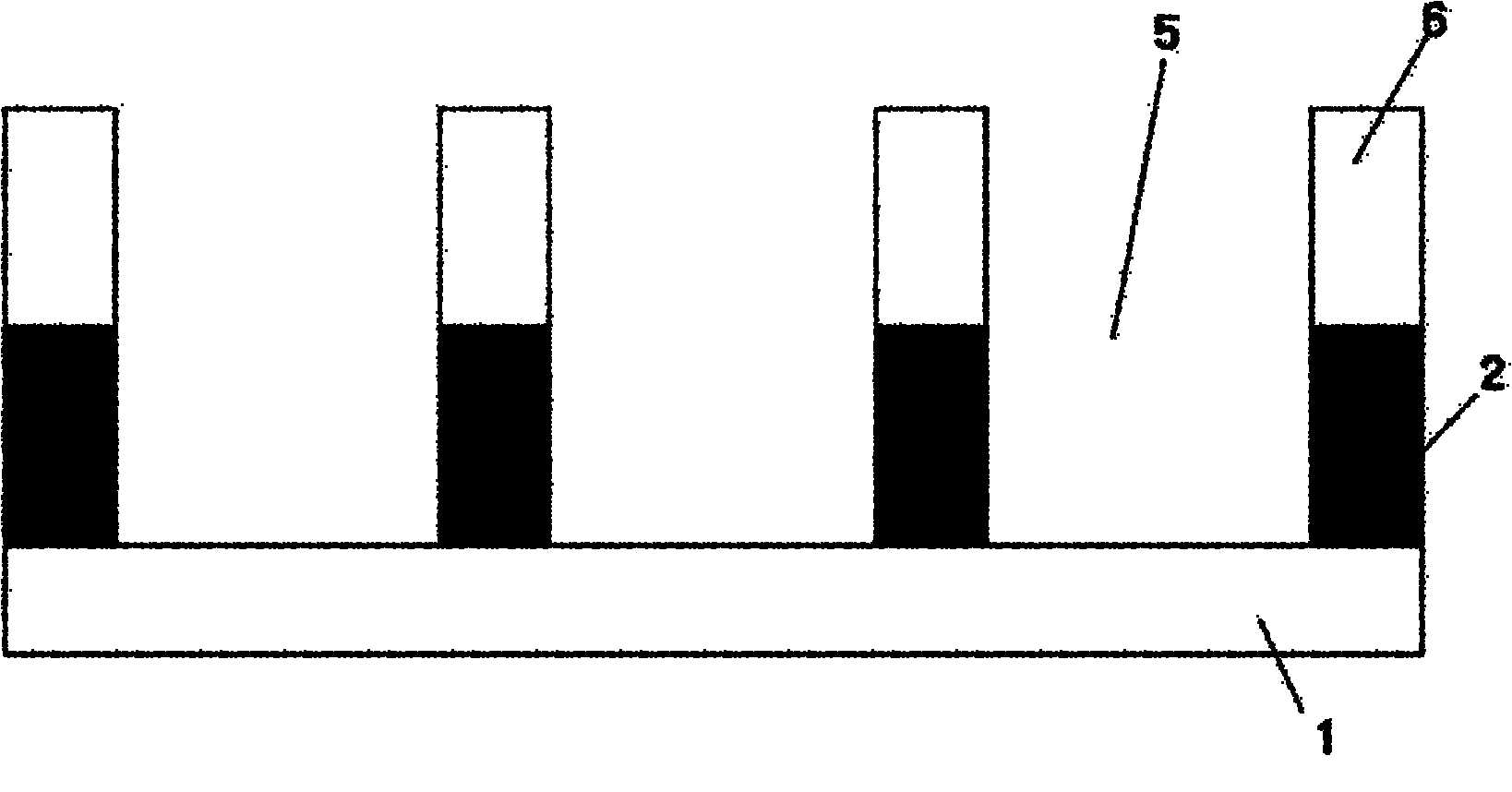

[0073] A glass substrate for color filters on which a low-reflection chrome-based black matrix was formed was prepared. The width of the black matrix is 20 μm, the length of the opening for forming a pixel is 280 μm, and the width is 80 μm. On the surface of the glass substrate on which the black matrix was formed, a positive resist was applied with a coater so that the thickness after drying was 8 μm, and air drying was performed at 50° C. or lower.

[0074] UV exposure was performed from the backside of the glass substrate coated with positive resist. Next, it was developed with a 3% trisodium phosphate aqueous solution, washed with water, neutralized with a 1% aqueous solution of phosphoric acid, washed with water, and dried. The height of the barrier rib formed from the positive resist layer formed on the black matrix was 8 μm. A color filter ...

Embodiment 2

[0076] Example 2 (Preparation of a color filter substrate having partition walls formed on a black resin type black matrix)

[0077] A glass substrate for color filters on which a black resin type black matrix was formed was prepared. The black matrix has a thickness of about 2 μm and a width of 20 μm, and the openings for forming pixels are 280 μm long and 80 μm wide. In the same manner as in Example 1, the same positive-type resist used in Example 1 was applied to the surface of the glass substrate on which the black matrix was formed with a coater so that the thickness after drying became 6 μm, and the process was carried out at 50° C. or lower. Air dry. UV exposure was performed from the backside of the glass substrate coated with positive resist. Next, it was developed with a 3% trisodium phosphate aqueous solution, washed with water, neutralized with a 1% aqueous solution of phosphoric acid, washed with water, and dried. The height of the barrier ribs formed of the po...

Embodiment 3

[0078] Example 3 (manufacture of color filter by ultraviolet curable inkjet printing method)

[0079] (a) Miniaturization treatment using pigment

[0080] As the pigment used, prepare PR254 (red pigment-1), PR177 (red pigment-2), PG36 (green pigment-1), PY139 (yellow pigment-1), PY138 (yellow pigment-2), PY150 (yellow pigment Pigment-3), PB15:6 (blue pigment-1) and PV23 (purple pigment-1), these pigments were micronized with crushed table salt. According to the conventional method, each pigment was loaded into a kneader equipped with a pressure cover at a mass ratio of 1.7:1.3 with ground salt and diethylene glycol, kneaded for 7 hours, and ground. The obtained ground material was poured into water, stirred to dissolve common salt and diethylene glycol, filtered and washed with water, and each pigment press cake was obtained. The pigment component in each pigment press cake is 35-45%. In addition, the average particle diameter of the pigment is about 30-40 nm.

[0081] (b)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com