Method for fabricating casting-type polyurethane elastomer tire

A technology of polyurethane tire and manufacturing method, applied in tires, household appliances, other household appliances, etc., can solve problems such as separation of wheel hub and tread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

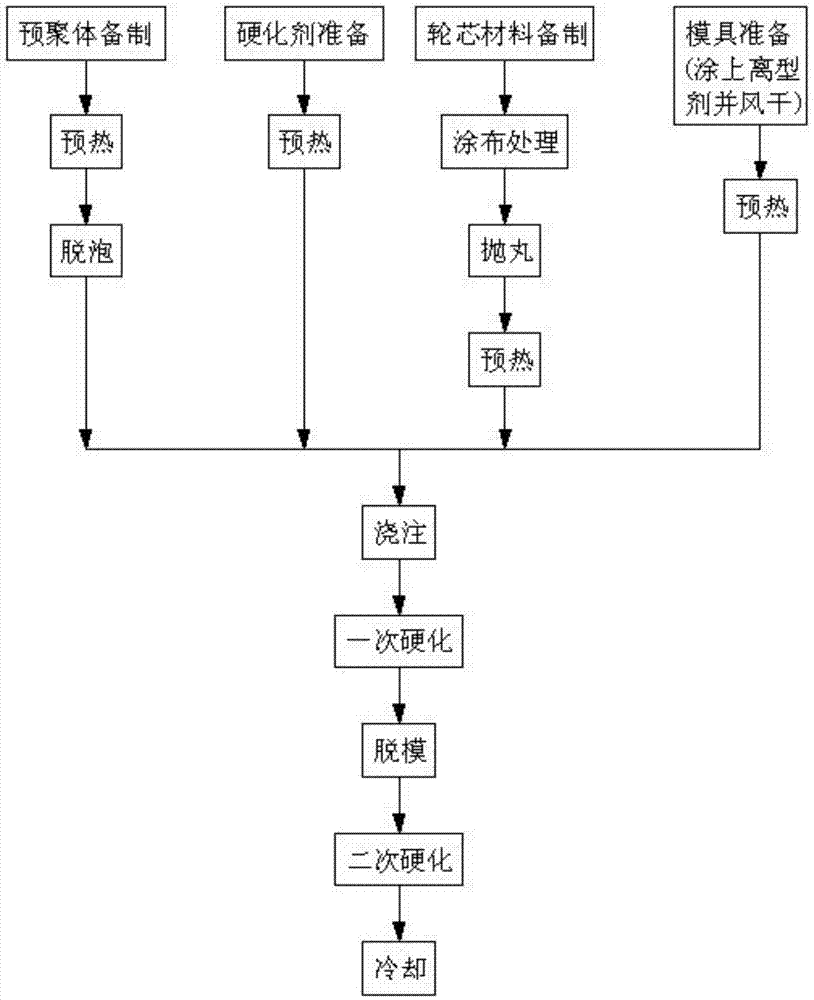

[0047] Casting type elastomeric polyurethane tire manufacturing method, such as figure 1 shown, including the following steps:

[0048] Step A. Material Preparation

[0049] (1) Preparation of prepolymer and hardener

[0050] Select polyurethane with NCO weight content of 4.20%-4.47%; select hardener: MOCA; MOCA chooses C13H12CL2N2 with a melting point of 98°C-110°C, and the amine value of MOCA is between 7.4-7.6 (mol / g); NCO equivalent is 940%~1000%;

[0051] (2) Preparation of wheel core material

[0052] Select castings and aluminum parts with a diameter of more than 170mm and steel pipes with a diameter of more than 204mm; in this embodiment, the diameter of the castings and aluminum parts is 178mm; The material is STKM13A;

[0053] Step B. Coating Treatment

[0054] Select an adhesive with a solid content of 18.50-20.50% (weight), mix 1.2-1.8 kg of MEK per 1 kg of adhesive, and then stir; put the wheel core material in the glue sprayer to apply the adhesive, Finall...

Embodiment 2

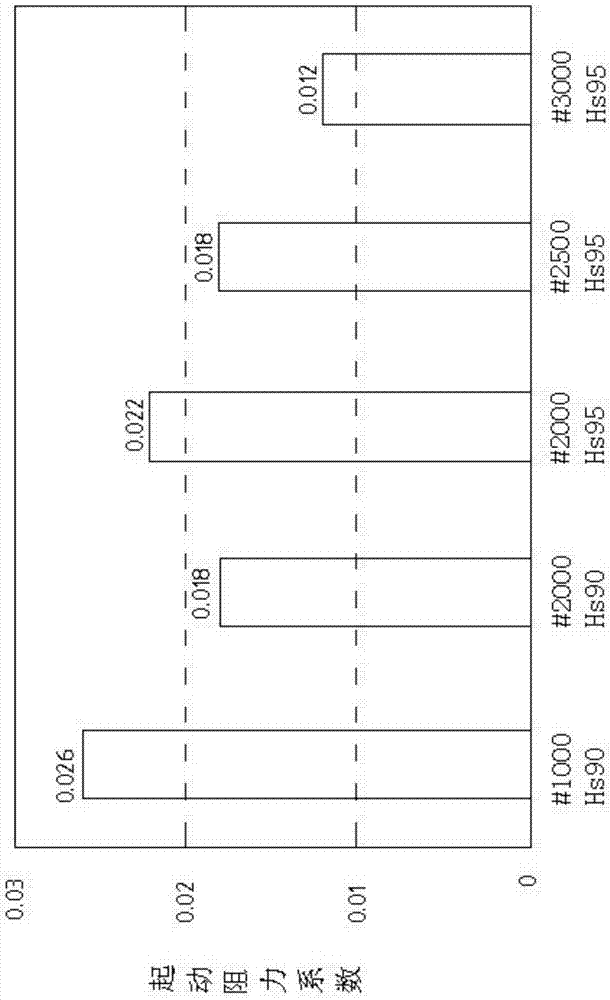

[0083] The basic process is the same as in Example 1, except that polyurethane and hardener are poured into the mold in a ratio of 100:10 (by weight).

Embodiment 3

[0085] The basic process is the same as that of Example 1, except that polyurethane and hardener are poured into the mold in a ratio of 100:15 (by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com