Polybutylene terephthalate resin composition and injection-molded article

A technology of polybutylene terephthalate and resin composition, which is applied in the field of polybutylene terephthalate resin composition, can solve problems such as difficulties in flame retardancy, and achieve the effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7、 comparative example 1~23

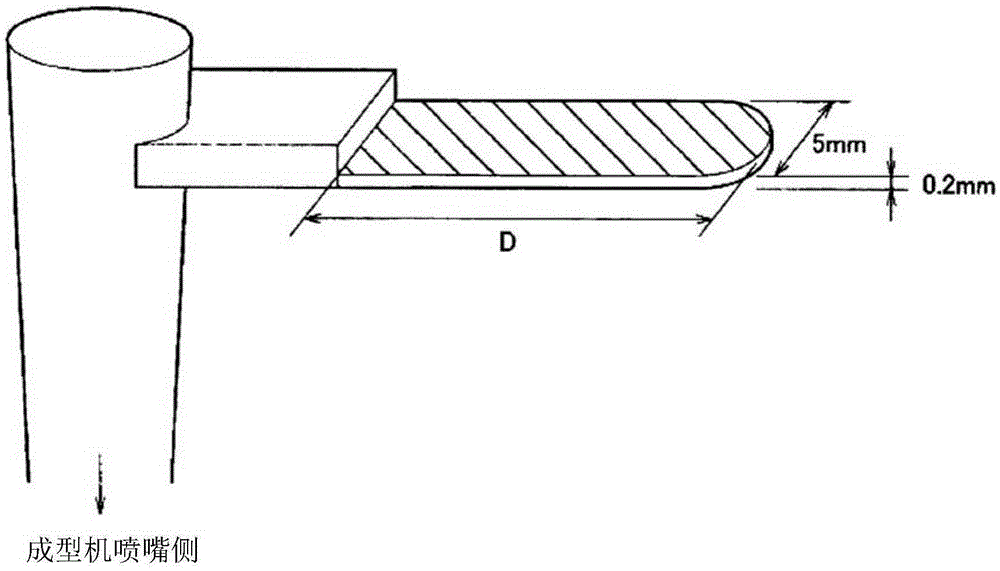

[0094] In each example and comparative example, for (A) polybutylene terephthalate resin (PBT), (B) brominated flame retardant, (C) antimony-based flame retardant aid, (D) talc, (E) Polyhydric hydroxyl compound, (F) anti-dripping agent, (G) glass fiber, respectively mixed the parts shown in Table 1 to Table 3 below, and prepared PBT resin composition by the method described later. Next, the following evaluations were performed using the obtained PBT resin composition.

[0095] In addition, the above-mentioned each component is specifically as follows.

[0096] PBT1 (IV=0.88): manufactured by Win-Tech Polymer Co., Ltd.

[0097] PBT2 (IV=0.69): manufactured by Win-Tech Polymer Co., Ltd.

[0098] PBT3 (IV=0.45): manufactured by Win-Tech Polymer Co., Ltd.

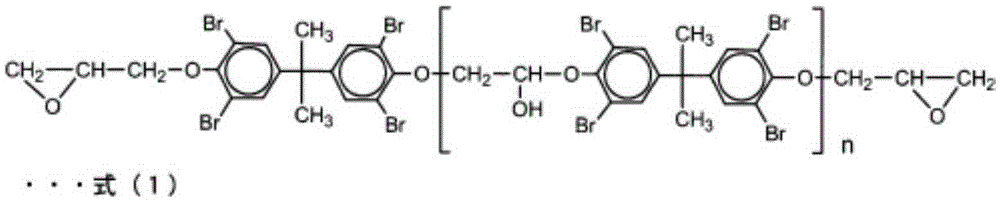

[0099] Flame retardant 1 (brominated epoxy flame retardant (Br-EP)): F3100 manufactured by Buromokemu Far East Co., Ltd., bromine content: about 52% by mass

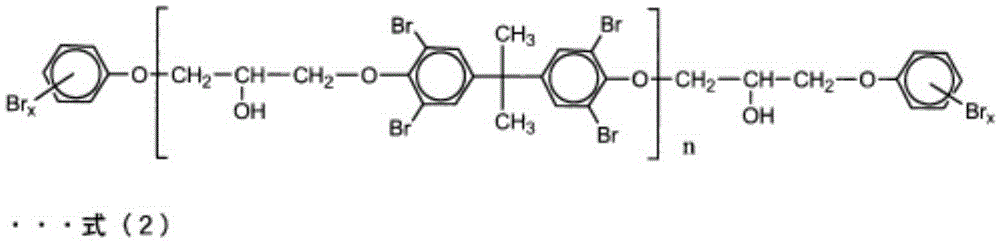

[0100] Flame retardant 2 (brominated polyacrylate flame retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flow length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com