Synchronous four-ridge sawtooth type dynamic clearance changing internal mixer rotor

An internal mixer and sawtooth type technology, which is applied in the field of four-edged sawtooth type dynamic variable gap internal mixer rotor, can solve the problems of high shear stress, rubber burning, temperature rise, etc., to improve the quality and efficiency of rubber mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

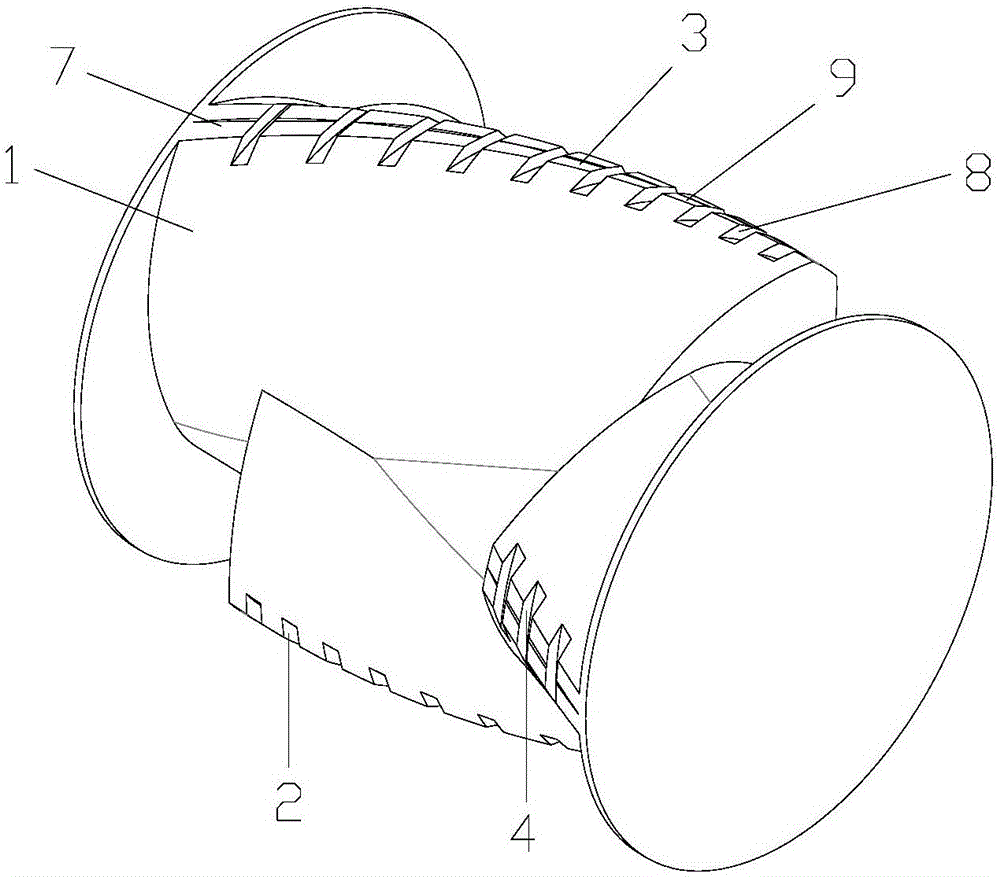

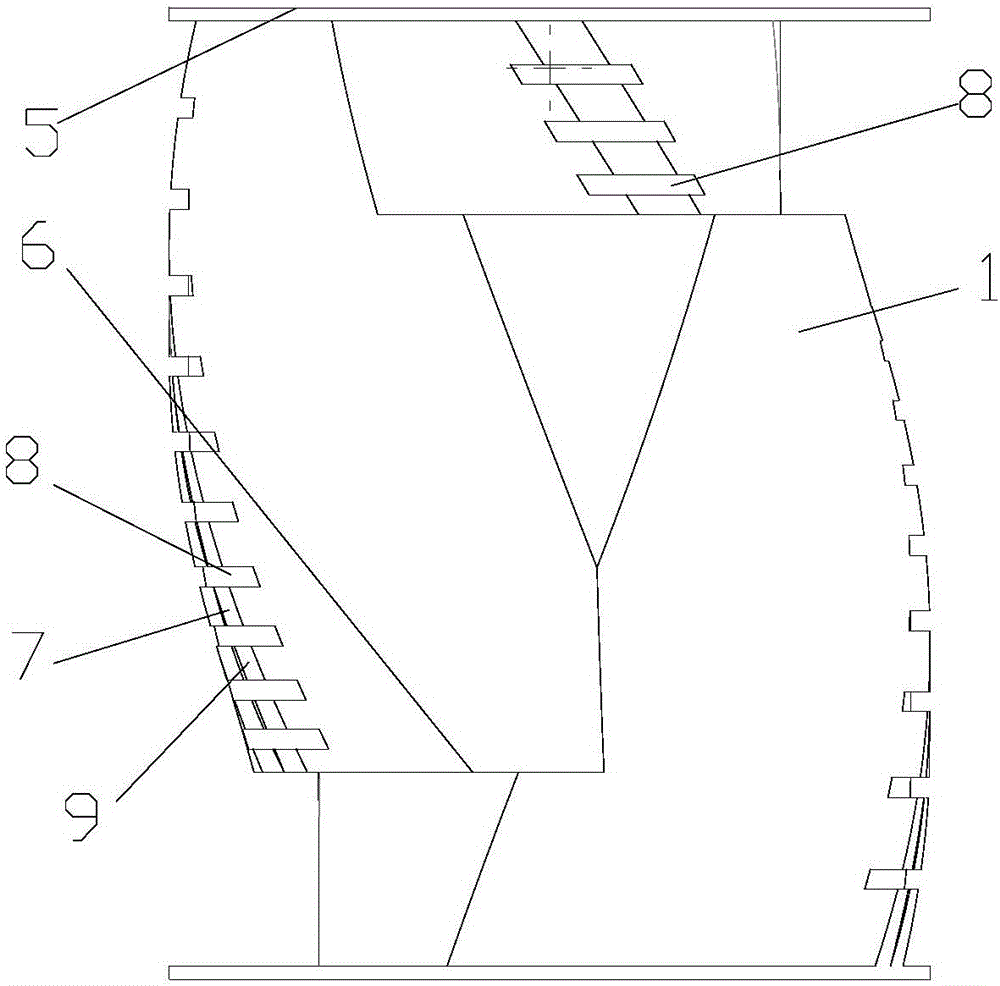

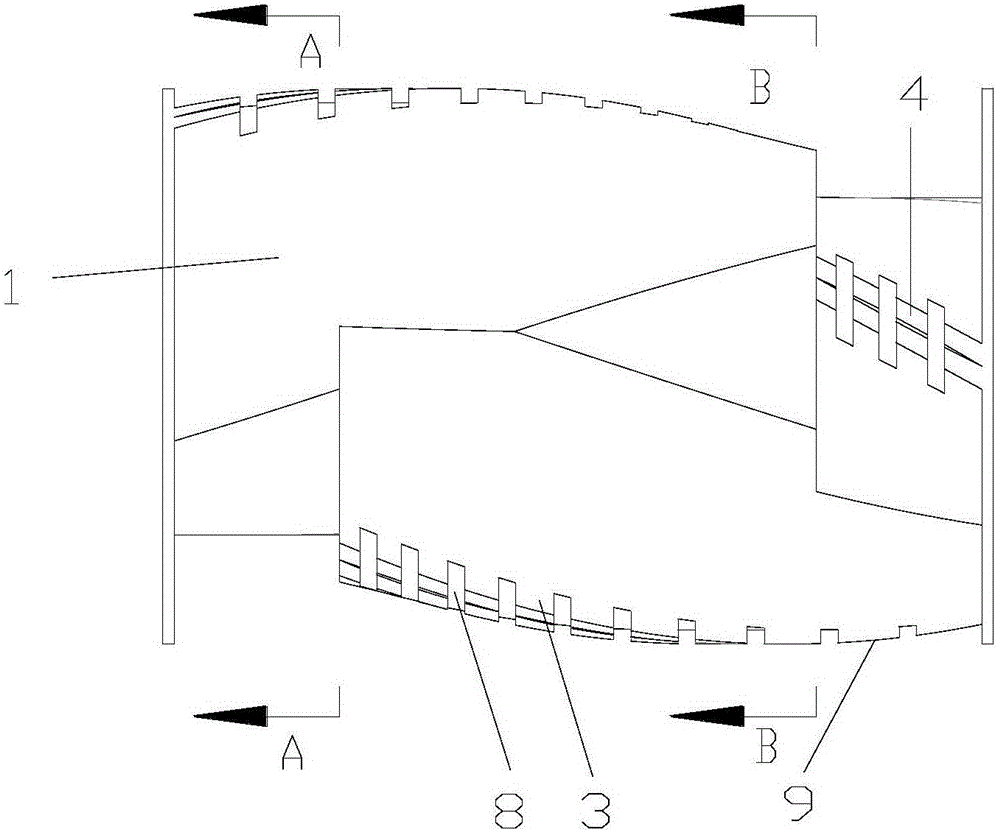

[0041] In one embodiment, the rotor of the synchronous four-edged saw-tooth type internal mixer with dynamic variable clearance includes a rotor body 1, and the rotor body 1 is provided with four ribs 2, including two long ribs 3 and two short ribs 4 , the ribs 2 spirally extend from both ends of the rotor body 1 to the middle, including a starting end 5 and a terminal end 6; a number of tooth grooves 8 are respectively arranged on the tops 7 of the ribs 2, along the starting end 5 In the direction to the terminal end 6, the width difference of the tooth grooves 8 on each rib 2 is constant, and the distance between the tooth grooves 8 gradually becomes smaller.

[0042] One long edge 3 and one short edge 4 start from one end of the rotor body 1, and the direction of rotation of the two long edges 3 is opposite to the center of symmetry, and the direction of rotation of the two short edges 4 is opposite Symmetrical to the center, the helix angle of the long edge 3 ranges from 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com