High-multilayer circuit board and manufacturing method thereof

A manufacturing method and circuit board technology, applied in multilayer circuit manufacturing, circuit substrate materials, printed circuit manufacturing, etc., can solve problems such as bubble residue, resin voids, interlayer reliability test failure, etc., to improve the amount of glue filling, Effect of improving heat resistance and insulation, and solving misalignment between laminated layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

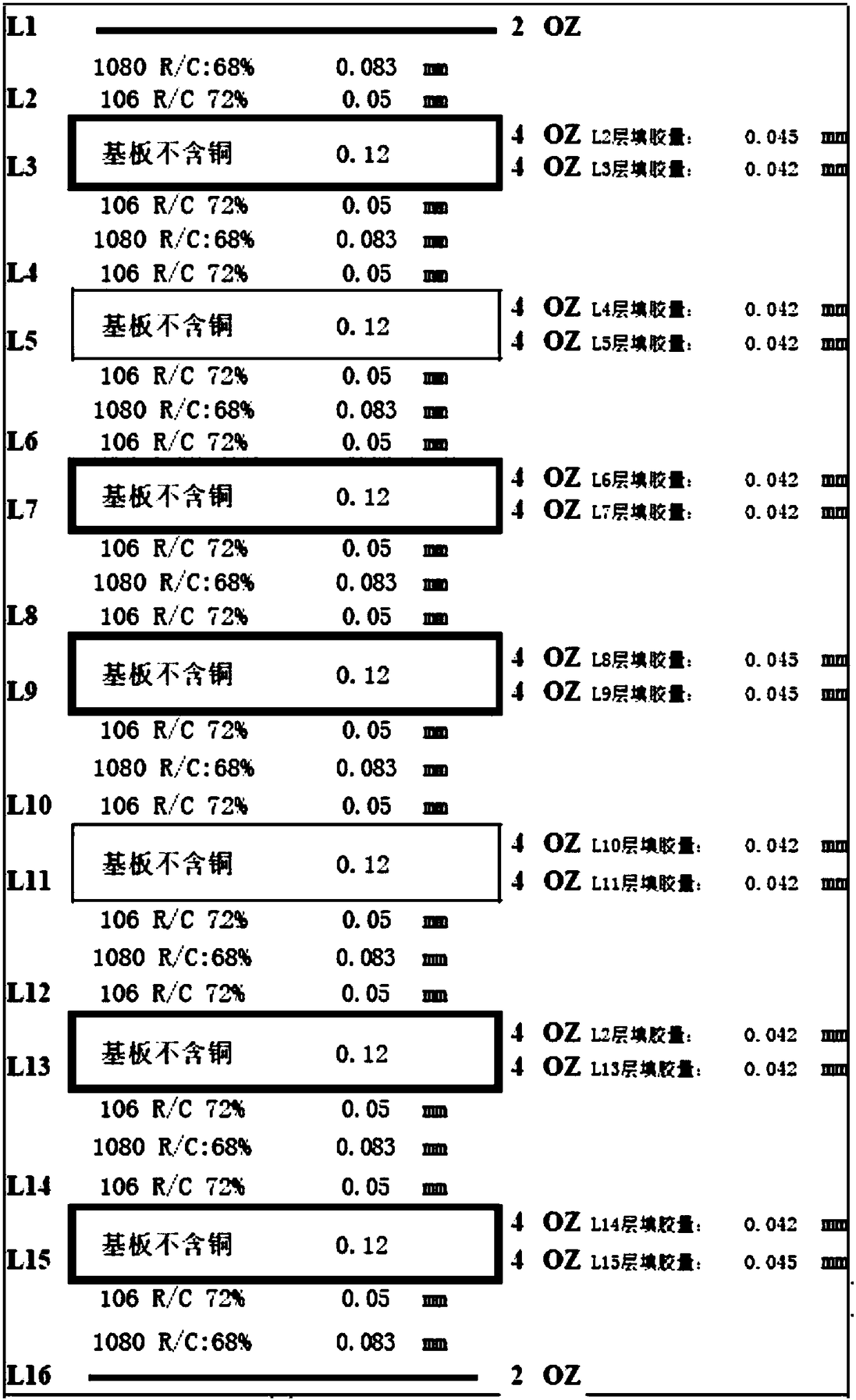

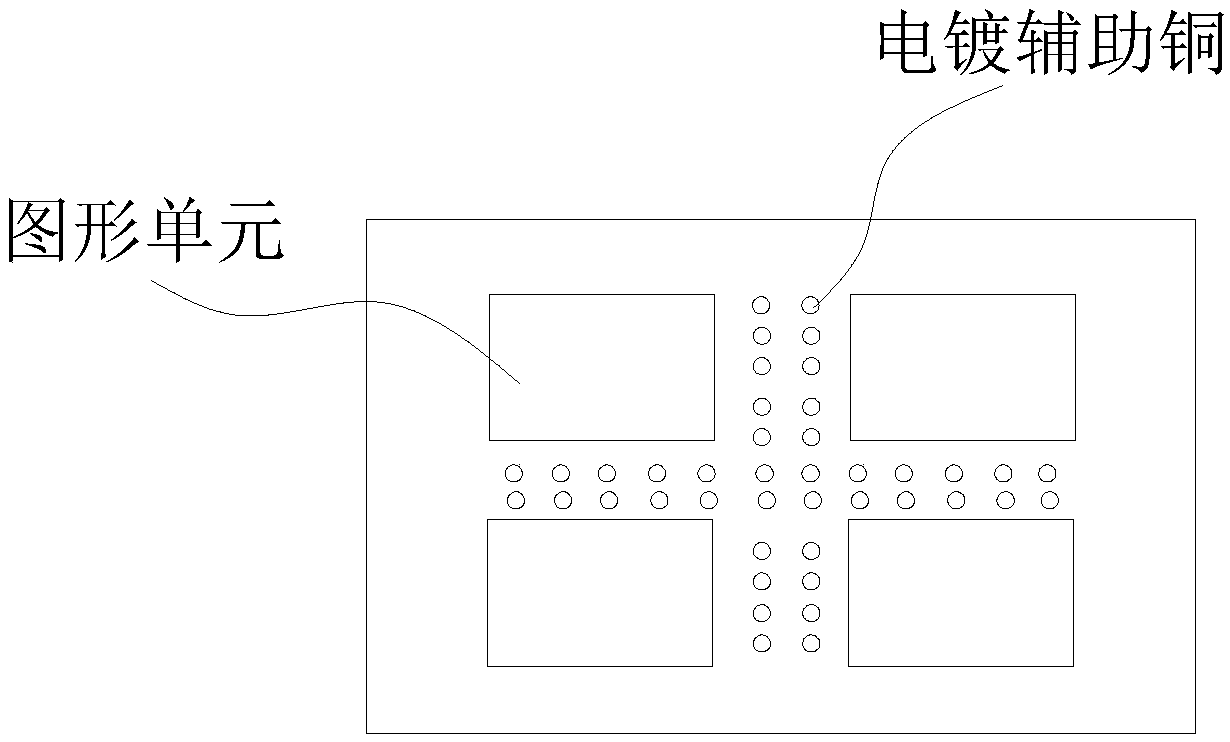

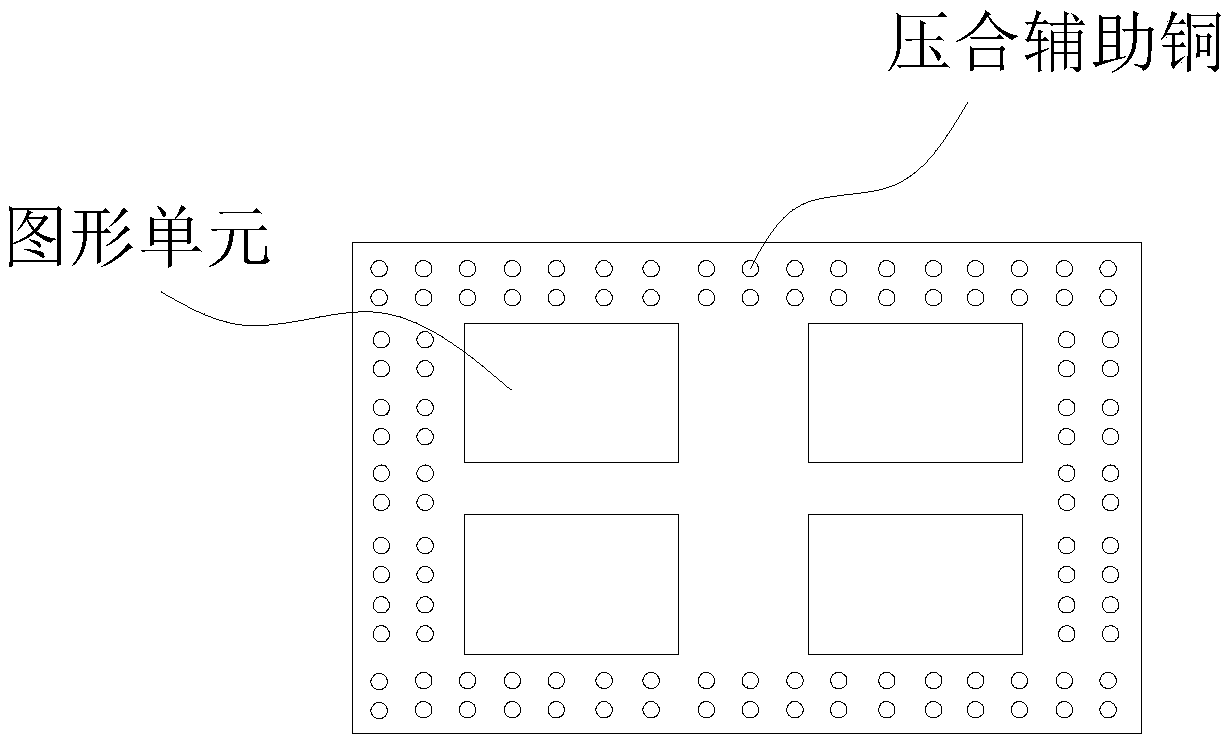

[0022] combine figure 1 , this program designs a high-level circuit board including 16 layers of circuits. The high-level circuit board includes two outer layers of copper foil and seven inner layers of substrates. The upper and lower surfaces of each inner layer substrate are covered with inner layers of copper foil circuits. And the thickness of the outer copper foil is 70um (2 oz / ft 2 ), the copper foil thickness of the inner substrate is 137.2um (4 oz / ft 2 ), the inner substrate is an epoxy resin substrate, and the thickness of the resin is 0.12mm (without copper). At the same time, there are 106 prepregs, 1080 prepregs and 106 prepregs in sequence between any two adjacent inner substrates (L3 layer to L15 layer), and between the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com