Gas pipeline drag reduction agent and preparing method thereof

A technology for gas transmission pipeline and drag reducing agent, which is applied in the field of polymer compound composition and pipeline system, can solve the problems of limited drag reduction effect, etc., and achieve the effects of good drag reduction effect, mild reaction conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step is to measure 18 parts of CS2, drop them into the mixture of 10 parts of hydrazine hydrate and water under stirring, reflux for a certain period of time in the temperature range of 90~95°C, then cool in an ice-water bath for a period of time, filter with suction, and continue to react the mother liquor The two and three products were combined, washed successively with ethanol and ether, and recrystallized with boiling water to obtain symmetrical dithiosemicarbazide;

[0022] In the second step, 10 parts of symmetrical dithiosemicarbazide and 10 parts of long-chain acid are dissolved in pyridine solvent, protected by nitrogen gas, and refluxed at 140°C to 220°C by temperature programming method, reacted for 3 to 4 hours, and cooled to At room temperature, the product was recrystallized.

Embodiment 2

[0024] The first step, measure 20 parts of CS2, drip in the mixed solution of 10 parts of hydrazine hydrate and water under stirring, synthesize under the same condition as in Example 1 to obtain symmetrical thiosemicarbazide; second step, mix 10 parts of Symmetrical dithiosemicarbazide and 10 parts of long-chain acid are dissolved in pyridine solvent, protected by nitrogen, refluxed at 140°C-220°C by temperature programming method, reacted for 3-4 hours, cooled to room temperature, and recrystallized to obtain the product.

Embodiment 3

[0026] The first step, measure 22 parts of CS2, drip in the mixed solution of 10 parts of hydrazine hydrate and water under stirring, synthesize under the same condition as in Example 1 to obtain symmetrical thiosemicarbazide; second step, mix 10 parts of Symmetrical dithiosemicarbazide and 10 parts of long-chain acid are dissolved in pyridine solvent, protected by nitrogen, refluxed at 140°C-220°C by temperature programming method, reacted for 3-4 hours, cooled to room temperature, and recrystallized to obtain the product.

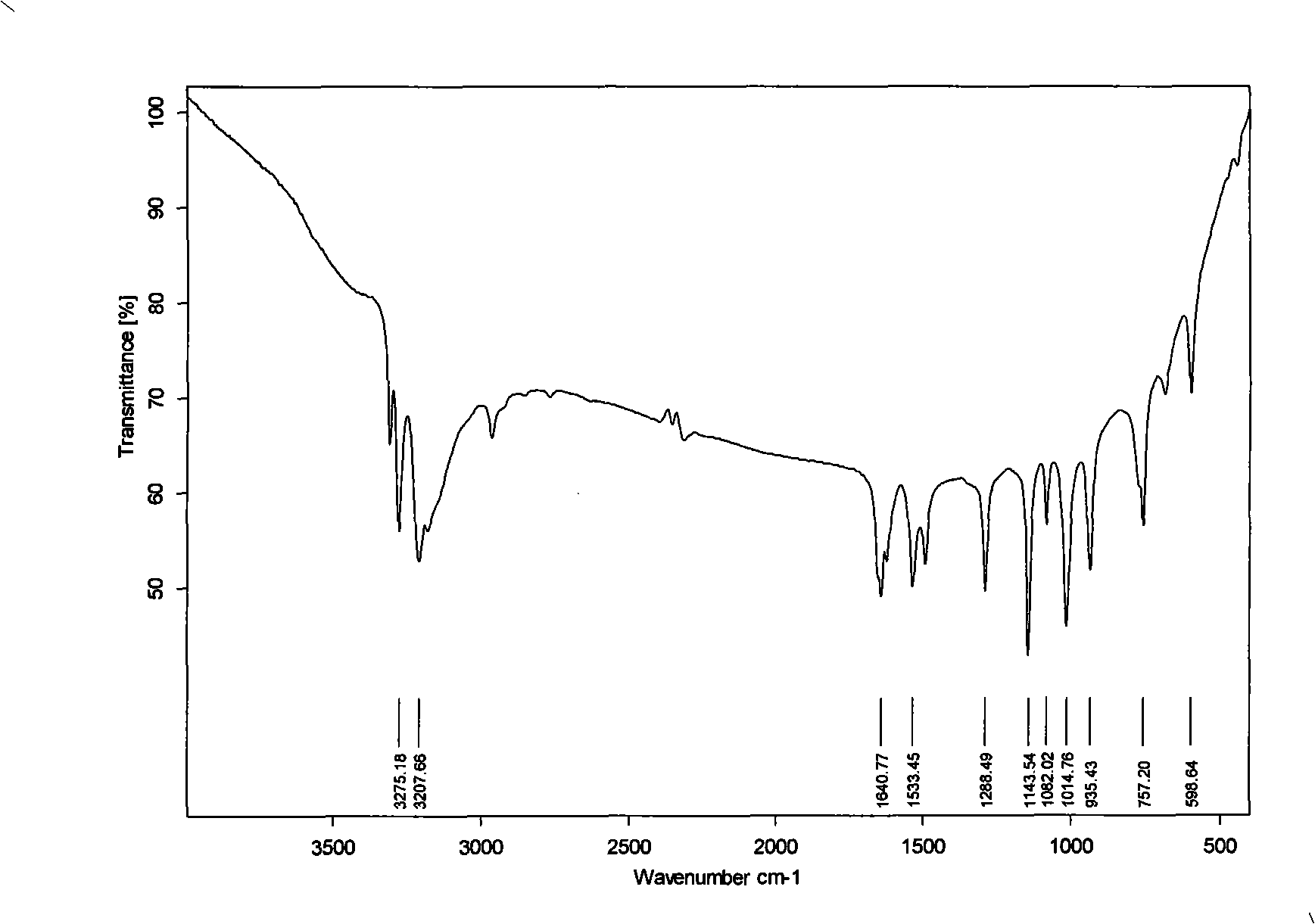

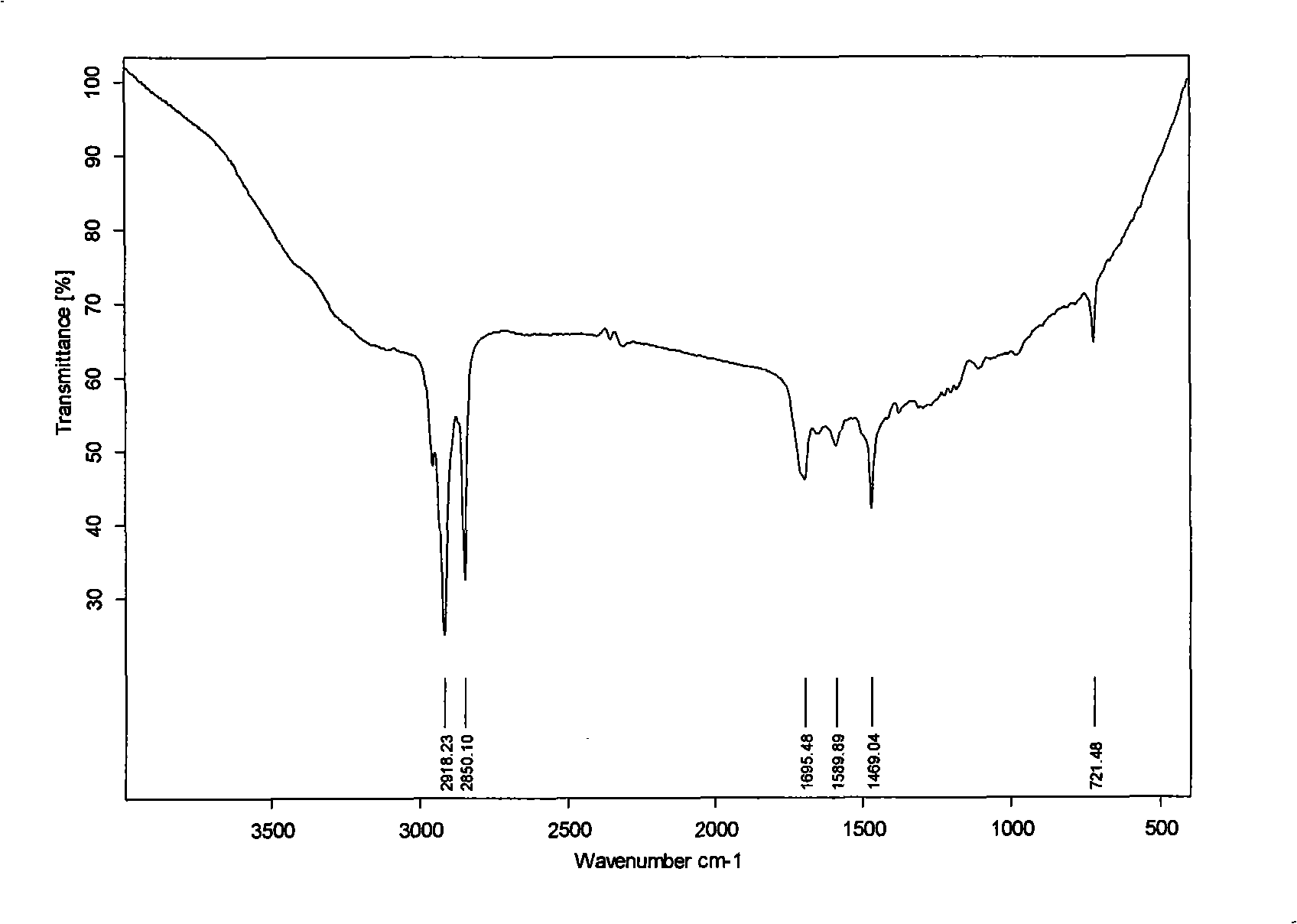

[0027] The product of above-mentioned embodiment is done infrared spectroscopic test, and result is as follows: figure 1 , figure 2 shown.

[0028] The absorption of the group, the spectrum of the compound where the C=S group is connected to the nitrogen atom has an absorption peak in the general C=S stretching vibration range, in addition, at 1563 ~ 700cm -1 In the broad region of , several absorption peaks can be attributed to vibrations involving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com