Preparation method of titanium alloy bar for pedicle screw

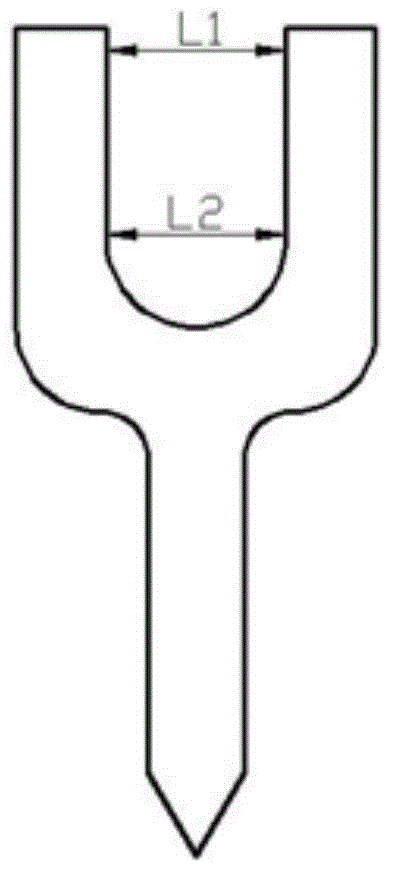

A pedicle screw and titanium alloy technology, which is applied in the field of preparation of titanium alloy rods for pedicle screws, can solve the problems of stress imbalance and shrinkage of the U-shaped notch of pedicle screws, and achieve a simple preparation method , suitable for mass production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

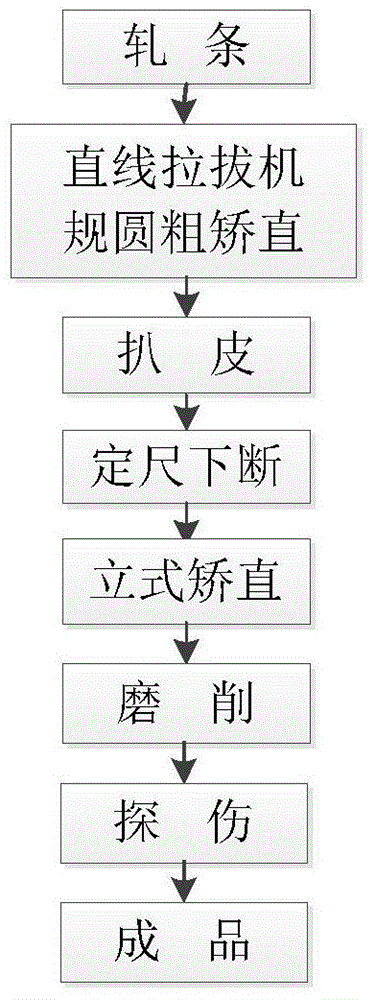

[0021] A kind of preparation method of titanium alloy bar material for pedicle screw of the present invention, such as figure 1 As shown, it specifically includes the following steps:

[0022] Step 1: Use a linear drawing machine to carry out rough straightening of the titanium alloy strip billet at a temperature of 870 ° C to 920 ° C. The hole die of the drawing machine is The speed of the drawing machine is controlled at 5-6m / min to obtain the billet;

[0023] Step 2: Use a peeling machine to peel off the blank bar obtained in step 1. The running speed of the peeling machine is 2-3m / min, and the surface defects are removed. 3000~3050mm, to get the stripped bar;

[0024] Step 3: Use a vertical electric heating straightening machine to straighten the peeled bar obtained in step 2. The pressure is 0.005-0.3MPa, the straightening current is 1500-1670A, and the current is heated for 30-45s with an interval of 10-25s , and then heated for 20-35s to obtain straightened rods;

...

Embodiment 1

[0035] Step 1: Use a linear drawing machine to carry out rough straightening of the titanium alloy strip billet at a temperature of 870 ° C. The hole die of the drawing machine is The speed of the drawing machine is controlled at 5m / min to obtain the billet;

[0036] Step 2: Use a peeling machine to peel off the blank bar obtained in step 1. The running speed of the peeling machine is 2m / min to remove the surface defects. 3050mm, get the bar after skinning;

[0037] Step 3: Use a vertical electric heating straightening machine to straighten the peeled bar obtained in step 2. The pressure is 0.005MPa, the straightening current is 1650A, and the electric current is used to heat for 37s, with an interval of 20s, and then heated for 27s to obtain straightening After the bar;

[0038] Step 4: Use a centerless grinder to grind the straightened bar obtained in step 3 for 5 passes. The grinding amount of the first 4 passes is 0.05 mm / pass, and the grinding amount of the 5th pass is...

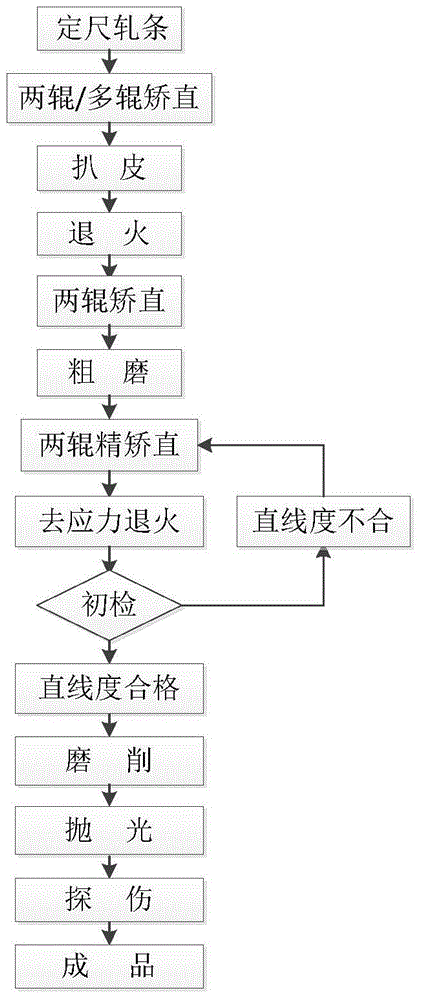

Embodiment 2

[0040] Step 1: Use a linear drawing machine to carry out rough straightening of the titanium alloy strip billet at a temperature of 890 ° C. The hole die of the drawing machine is The speed of the drawing machine is controlled at 5.5m / min to obtain the billet;

[0041] Step 2: Use a peeling machine to peel off the blank bar obtained in step 1. The running speed of the peeling machine is 2.5m / min to remove the surface defects. ~3500mm, to get the stripped bar;

[0042] Step 3: Use a vertical electric heating straightening machine to straighten the peeled bar obtained in step 2. The pressure is 0.15MPa, the straightening current is 1500A, and the current is heated for 30s with an interval of 10s, and then heated for 35s to obtain straightening After the bar;

[0043] Step 4: Use a centerless grinder to grind the straightened bar obtained in Step 3 for 4 passes, with a grinding amount of 0.05mm and a total machining allowance of 0.2mm, and conduct 100% by ultrasonic flaw detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com