Railway vehicle tractive transformer hanging beam

A technology for traction transformers and rail vehicles, which is applied in the directions of transformer/reactor installation/support/suspension, etc., which can solve problems such as complex dynamic stress and frequent acceleration loads of hanging beams, achieve high mechanical strength, improve welding automation level, and improve The effect of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

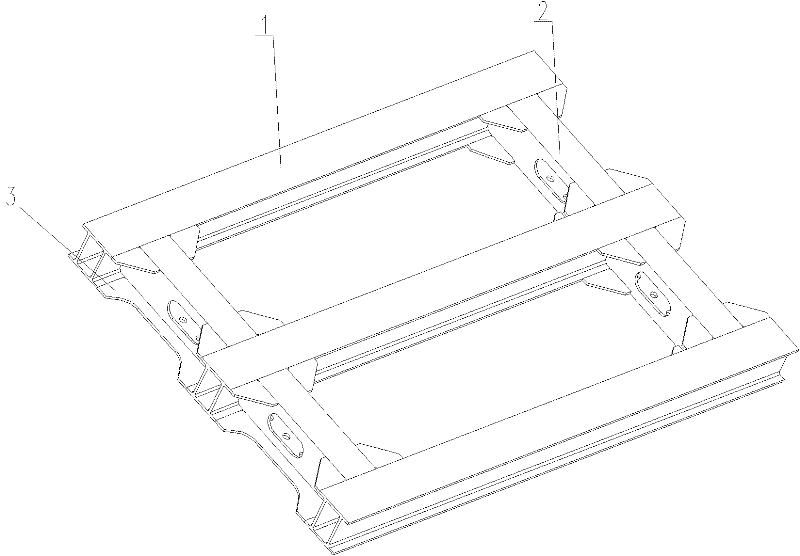

[0034] Example 1, such as Figure 1 to Figure 3 As shown, the rail vehicle traction transformer suspension beam mainly includes:

[0035] A frame structure composed of 3 beams 1 and 4 longitudinal beams 2 cross-connected,

[0036] The beams 1 are kept parallel to each other, and the longitudinal beams 2 are kept parallel to each other.

[0037] Welding is carried out at the connecting end between beam 1 and longitudinal beam 2,

[0038] The traction transformer of the rail vehicle is hoisted on the longitudinal beam 2 by bolts.

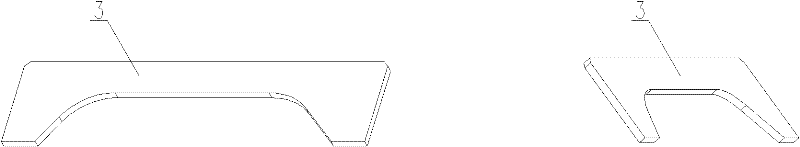

[0039] Among them, a reinforcing plate 3 is connected between two adjacent beams 1 , and a reinforcing plate 3 is connected between two adjacent beams 1 and longitudinal beams 2 .

[0040] The reinforcing plate 3 connected between two adjacent beams 1 is also connected to the adjacent longitudinal beams 2 at the same time.

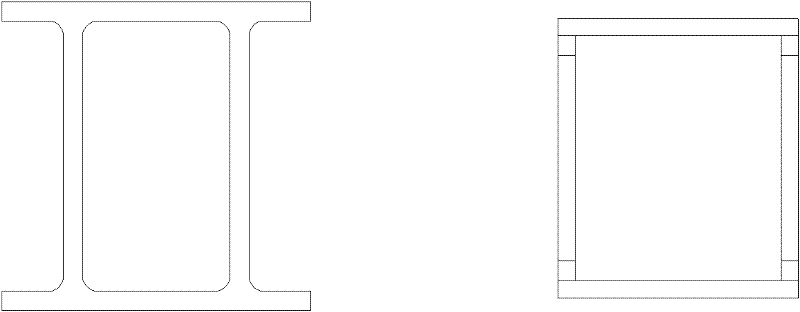

[0041] Both the beam 1 and the longitudinal beam 2 have aluminum alloy hollow profile structure, that is, the section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com