Actuator cylinder support structure

A technology of actuators and supports, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of high stress level, safety, and reduced service life of the afterburning cylinder, and achieve the goal of reducing stress level and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

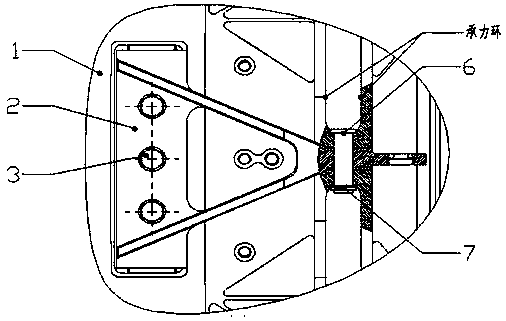

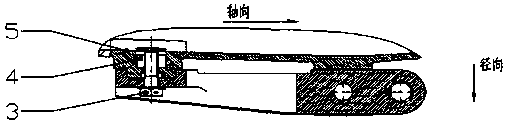

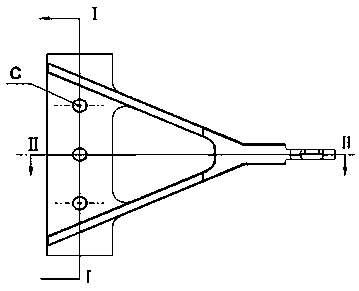

[0023] The invention achieves the purpose of greatly reducing the stress level of the actuator cylinder support and the force cylinder body by changing the connection mode of the actuator cylinder support and the force cylinder body. The mechanism of the present invention is shown as figure 1 with 2 shown.

[0024] The structure of the present invention is made up of booster cylinder 1, actuating cylinder support 2, bolt 3, supporting plate nut 4, mounting seat 5, pin 6, retaining ring 7. One end of the actuator support 2 is connected to the mounting seat 5 welded on the booster cylinder 1 through the bolt 3 and the supporting plate nut 5, and the other end is connected to the bearing ring on the booster cylinder 1 through the pin 6 , The retaining ring 7 is used to prevent the pin 6 from coming out. A notch structure is designed between the cylinder support 2 and the mounting seat 5, and the notch adopts an interference fit. Adopt small clearance to fit between pin 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com