Brick wall reinforcing structure

A technology for strengthening structures and brick walls, which is applied in building construction, building maintenance, construction, etc., can solve the problem that reinforced steel bars and brick walls cannot be coordinated to bear force, and achieves the effects of low cost, convenient construction and operation, and reduced stress levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

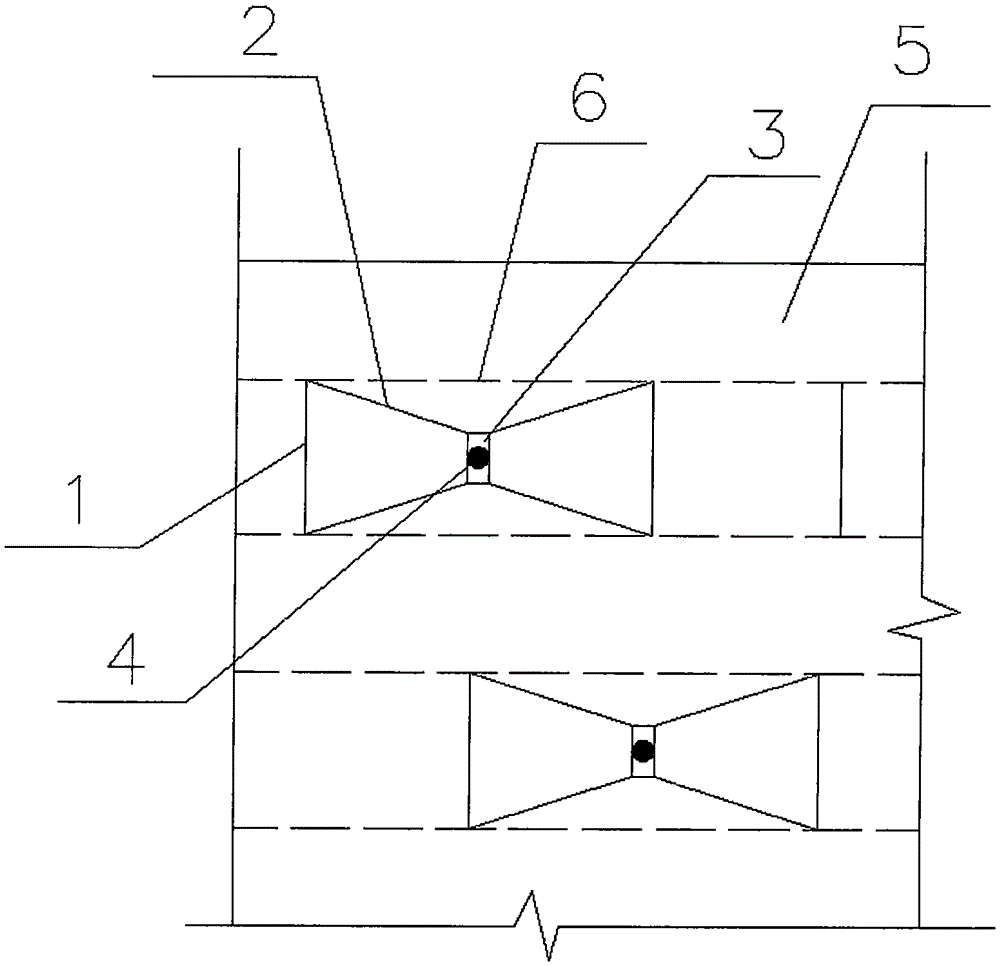

[0026] In the embodiment, the brick wall 5 is provided with reinforcement hoops 1 at intervals of 2.5 to 3 m at the mortar joints. The diameter of the reinforcement hoops 1 is 8 to 10 mm. Different rows of reinforcement hoops 1 are misplaced, and the steel bars of the reinforcement hoops 1 pass through the brick wall. 5 The horizontal mortar joints form a closed hoop, the surface of the brick wall 5 is provided with horizontal steel bars 6, the vertical spacing of the horizontal steel bars 6 is 150-300 mm, the diameter of the horizontal steel bars 6 is 8-10 mm, and the horizontal steel bars 6 are fixed by the anchor bars 4 Segmented prestressed tension, the length unit of segmented prestressed tension is the distance between hoop 1 of adjacent steel bars in the same row, horizontal steel bar 6 becomes broken line steel bar 2 after stretching, and the broken line at the point where the stretching length of adjacent rows is the largest The steel bar 2 is welded and fixed by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com