Metal material surface strengthening method based on mixed surface nanocrystallization technology

A metal material and surface strengthening technology, applied in the field of surface strengthening and modification of metal materials, can solve the problems of limited application, unsuitable surface treatment of large-sized metal parts, large surface roughness of products, etc. Easy maintenance and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

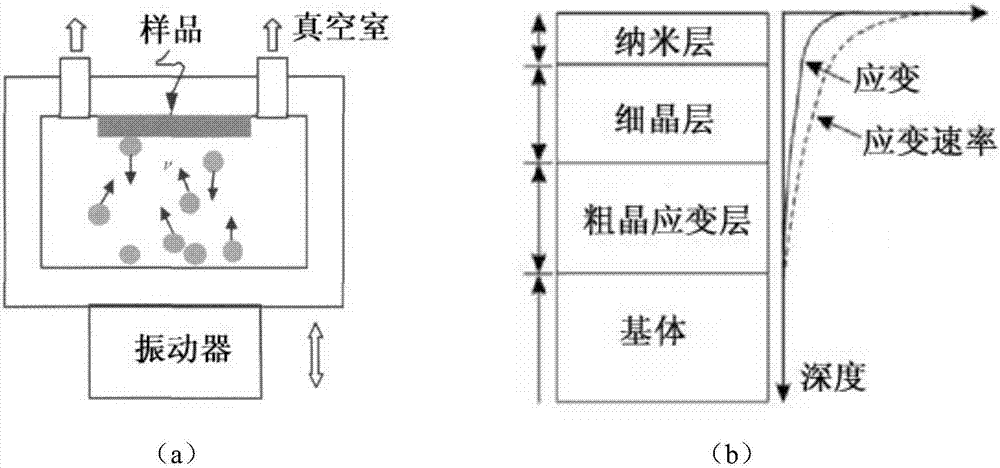

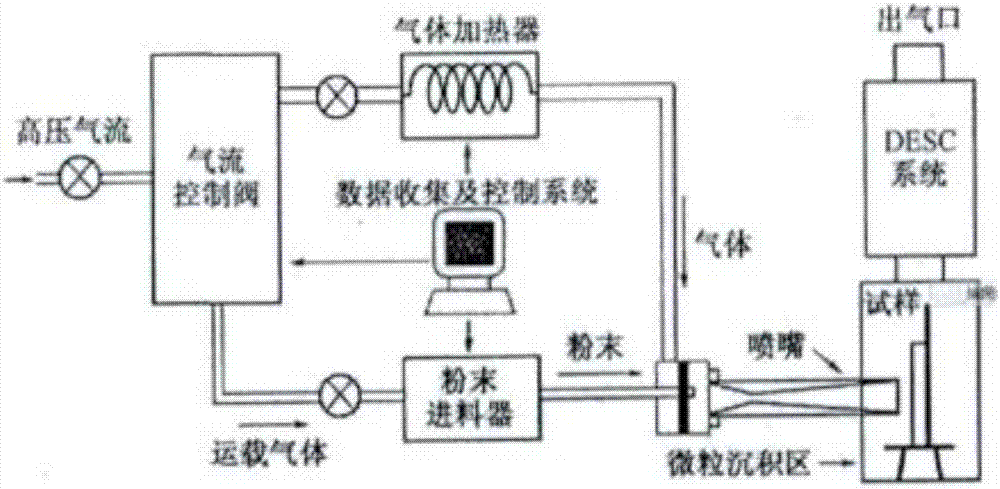

Embodiment 1

[0028] The present invention takes 2A14 aluminum alloy as processing object, 2A14 is Al-Mg-Si-Cu alloy, processes aluminum alloy plate of 500mm×500mm×5mm, and performs conventional grinding and polishing treatment on the surface of the sample. Use 1433 / 8558Progressive (DT1480) CNC shot peening machine to carry out supersonic particle bombardment surface treatment on aluminum alloy. The main parameters are: the projectile material is stainless steel S110, the projectile diameter is 0.3mm, the spray angle is 90°, the working pressure is 0.53MPa, and the airflow rate is 1200m / s, spray distance 130mm, spray time 10min. After the treatment, a nanolayer about 50 μm thick is formed on the surface of the material, and the surface crystal grains are formed by the 30 μm of the matrix (such as Figure 4 ) is reduced to 30nm of the nano-layer grain, the TEM bright field image of the surface nano-layer grain and the corresponding selected electron diffraction pattern and dark field image ...

Embodiment 2

[0031] Differences from Case 1:

[0032] Use 1433 / 8558Progressive (DT1480) CNC shot peening machine to carry out supersonic particle bombardment surface treatment on aluminum alloy. The main parameters are: the projectile material is WC, the projectile diameter is 0.5mm, the working pressure is 0.4MPa, and the spraying time is 20min. After the treatment, a layer of about 50 μm thick nano-layer is formed on the surface of the material, and the average grain size of the nano-layer on the surface is 50 nm. Figure 10 , with a surface roughness of 6.879 μm.

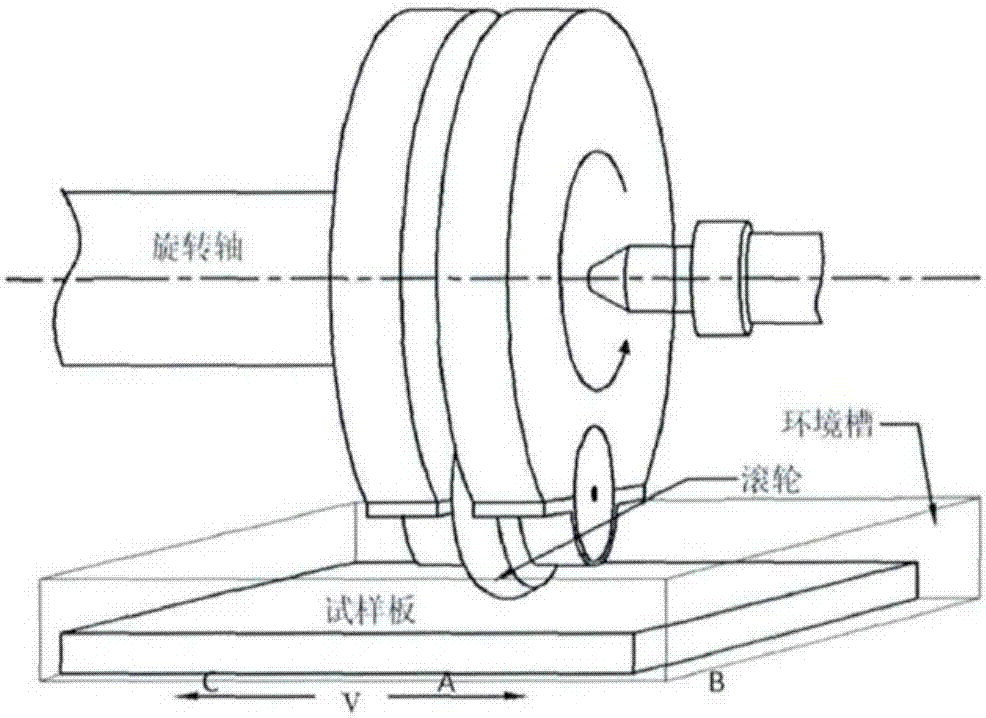

[0033] After the supersonic particle bombardment technology is used to nano-treat the surface of 2A14 aluminum alloy, the surface of the material is continued to be processed by surface mechanical rolling equipment. The rotation speed of the rotating shaft is 40r / min, and the diameter of the roller is 45mm. The sample can move left and right at a speed of 0.5mm / s, and the sample is rolled 30 times in an air environment at 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com