A kind of high-strength toughness and high-strength plasticity automobile steel and its preparation method

A high-strength plastic product, automotive steel technology, applied in high-strength and high-strength plastic-product automotive steel and its preparation, low-cost fields, can solve the problems of cracking and edge cracking, reduce the yield of auto parts and collision safety, and achieve low Effects of alloying element content, high comprehensive mechanical properties, and excellent impact toughness

Active Publication Date: 2022-02-25

CENT IRON & STEEL RES INST

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, cracks and edge cracks occur in the stamping process of the third-generation automobile steel, which reduces the yield of auto parts and the collision safety during use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] Example 1: Hot rolling and reverse phase transformation annealing to obtain low-cost, high-toughness, high-strength plastic product new-style automobile plate or bar, steel smelting and forging:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

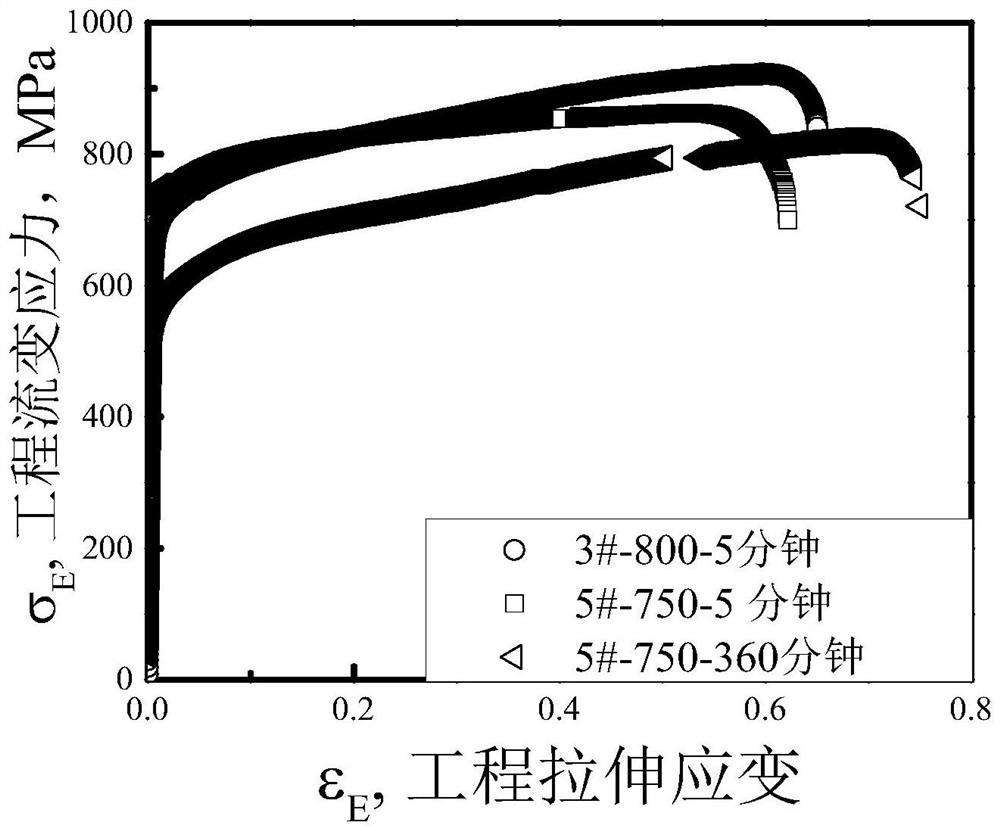

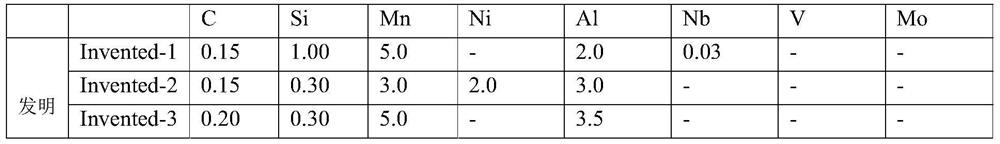

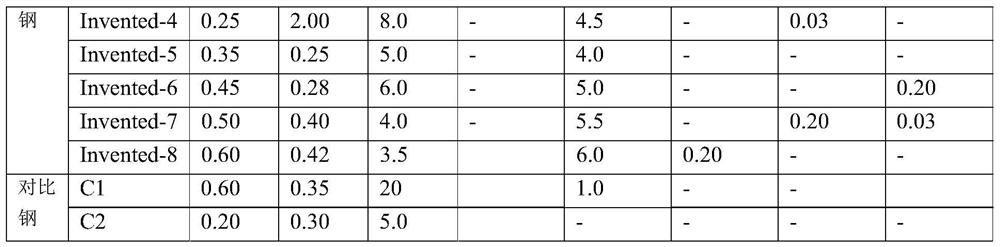

The invention relates to a high-strength toughness and high-strength plasticity automobile steel and a preparation method thereof, which belong to the technical field of manufacturing high-toughness, high-strength and high-strength plasticity automobile steel. Chemical composition of steel: C: 0.15‑0.60wt%, Si: 0‑2.0wt%, Ni: 0‑2.0wt%; Mn: 3.0‑6.0wt% and Al: 2.0‑6.0%, the rest is Fe and not Avoid impurity elements. On this basis, one or more of the following microalloying elements can be added, Nb: 0‑0.10wt%; V: 0‑0.10wt%; Ti: 0‑0.10wt% and Mo: 0‑0.10wt%, Cu : 0-0.50wt%, B: 0.0005-0.005wt%. The advantage is that through the alloying of C, Mn and Al, rolling and annealing in the dual-phase region, a multi-phase, multi-layer, and metastable microstructure is formed, and the V-type impact toughness at -40°C is not less than 120J , the strength-plastic product is not less than 50GPa%, and the cost is far lower than the traditional high-manganese steel and the comprehensive mechanical properties are much higher than the low-cost and high-performance of the medium-manganese steel. It can be used in the field of automobile body-in-white and transmission parts manufacturing in the form of rods or plates.

Description

technical field [0001] The invention belongs to the technical field of manufacturing high-toughness, high-strength, plastic-deposited automotive steel, and in particular provides a high-strength, high-strength, high-strength, plastic-deposited automotive steel and a preparation method thereof, namely: a multi-phase, multi-layered and metastable microstructure regulation and control Low-cost, high-strength, toughness and high-strength plasticity automotive steel and its preparation method. [0002] technical background [0003] In response to the requirements of light weight and high collision safety of automobiles, the steel for automobile body-in-white and steel for transmission parts is developing towards higher strength. Countries at home and abroad have carried out a large number of high-strength steel instead of low-strength steel steel development and high-strength steel forming technology research, forming Q&P high-strength plastic automotive steel with quenching and p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/08C22C38/12C22C38/14C22C38/16C21D8/00C22C33/04

CPCC22C38/02C22C38/08C22C38/04C22C38/06C22C38/12C22C38/14C22C38/16C22C38/002C22C33/04C21D8/005C21D2211/005C21D2211/008C21D2211/001

Inventor 曹文全王存宇徐海峰俞峰许达翁宇庆

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com