A kind of method utilizing ionic liquid electrodeposition to prepare ni-mo-p nano-alloy film electrode

A nano-alloy and thin-film electrode technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of high hydrogen-induced defects in the coating layer, significant hydrogen evolution catalytic activity, unstable plating solution composition, etc., and achieve good surface morphology and interface. The effect of bonding force, excellent hydrogen evolution catalytic activity, and good interfacial bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

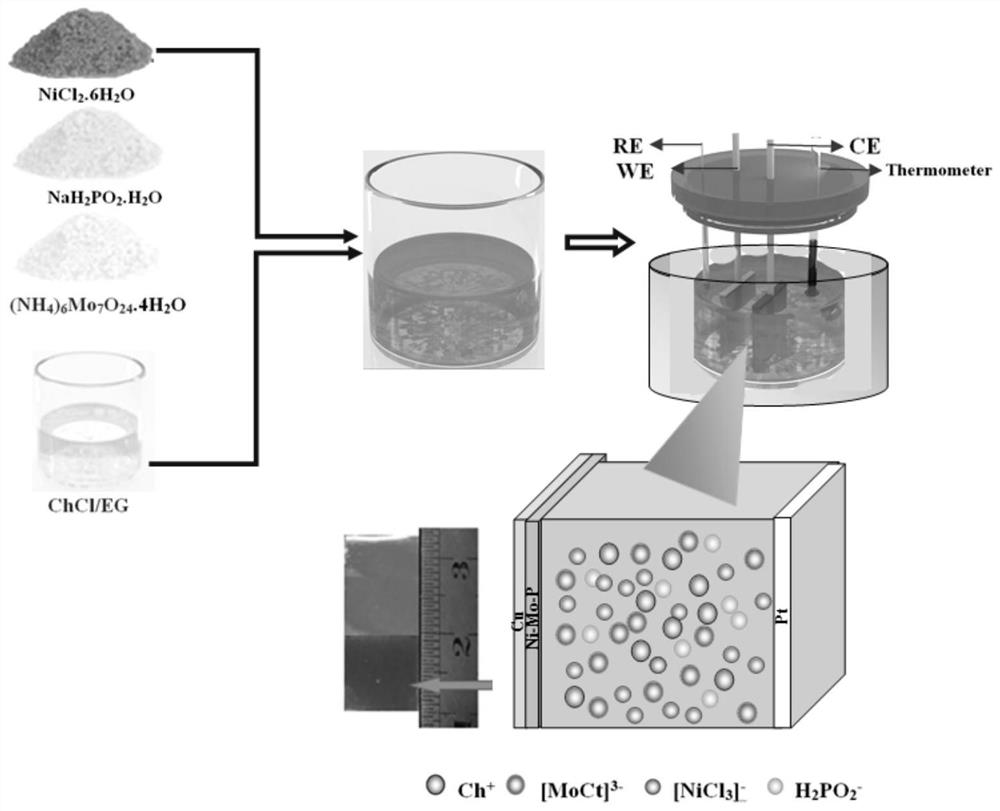

[0027] (1) Preparation of ionic liquid solvent: heat and mix dried choline chloride and ethylene glycol at 60°C in a molar ratio of 1:2 to obtain a colorless and transparent liquid, which is an ionic liquid;

[0028] (2) Preparation of ion plating solution: Take 50mL of the above-mentioned ionic liquid, add 0.05g of C 6 h 8 o 7 .H 2 O, stirred at 70°C for 20min, then 0.3g of (NH 4 ) 6 Mo 7 o 24 .4H 2 O was added into the above solution three times (0.1g each time, with an interval of 20 minutes), and continued to stir at 70°C for 40 minutes to form a light yellow solution, and then 0.6g of NaH 2 PO 2 .H 2 O continued to be added to the above mixed solution, stirred at 70°C for 30min to form a mixed solution without precipitation, and finally 8.06g of NiCl 2 .6H 2 O was added to the above mixed solution and continued to stir at 70°C for 1 hour to form a uniform, dark green solution without precipitation. In this plating solution, Ni 2+ :Mo 6+ is 20:1, Ni 2+ :HPO 2 ...

Embodiment 2

[0033] (1) The preparation of the ionic liquid solvent is the same as in Example 1;

[0034] (2) The preparation process of ion plating solution is the same as embodiment 1;

[0035] (3) Preparation of Ni-Mo-P nano-alloy thin film electrodes by electrodeposition is the same as in Example 1, except that the current density during electrodeposition is 30 mA / cm 2 ;

[0036] (4) Cleaning and drying of the Ni-Mo-P nano-alloy thin film electrodes are the same as in Example 1.

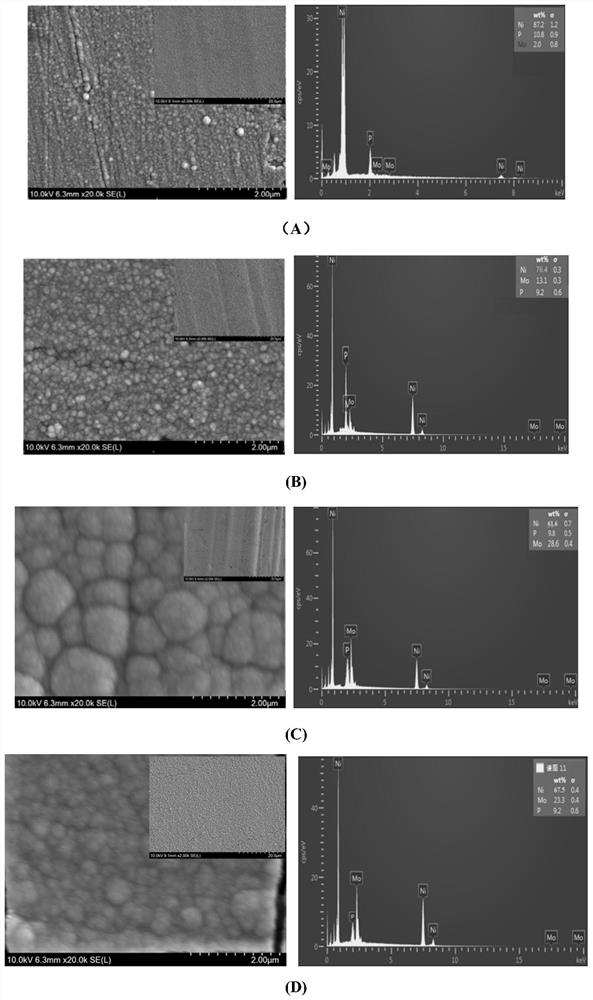

[0037] The surface of the Ni-Mo-P nano-alloy thin-film electrode obtained in Example 2 is still relatively smooth, the particle diameter slightly increases to 50-150nm, the Mo content in the alloy increases significantly to 11.2 wt%, and the P content changes little to 9.1 wt%, the phase composition is the same as in Example 1.

Embodiment 3

[0039] (1) The preparation of the ionic liquid solvent is the same as in Example 1;

[0040] (2) The preparation process of the ion plating solution is the same as in Example 1, except that the added C 6 h 8 o 7 .H 2 O is 0.1g, (NH 4 ) 6 Mo 7 o 24 .4H 2 O is 0.6g (3 times, 0.2g each time, with an interval of 20 minutes); in this plating solution, Ni 2+ :Mo 6+ is 10:1, Ni 2+ :HPO 2 - is 6:1;

[0041] (3) Preparation of Ni-Mo-P nano-alloy thin film electrode by electrodeposition is the same as in Example 2;

[0042] (4) Cleaning and drying of the Ni-Mo-P nano-alloy thin film electrodes are the same as in Example 1.

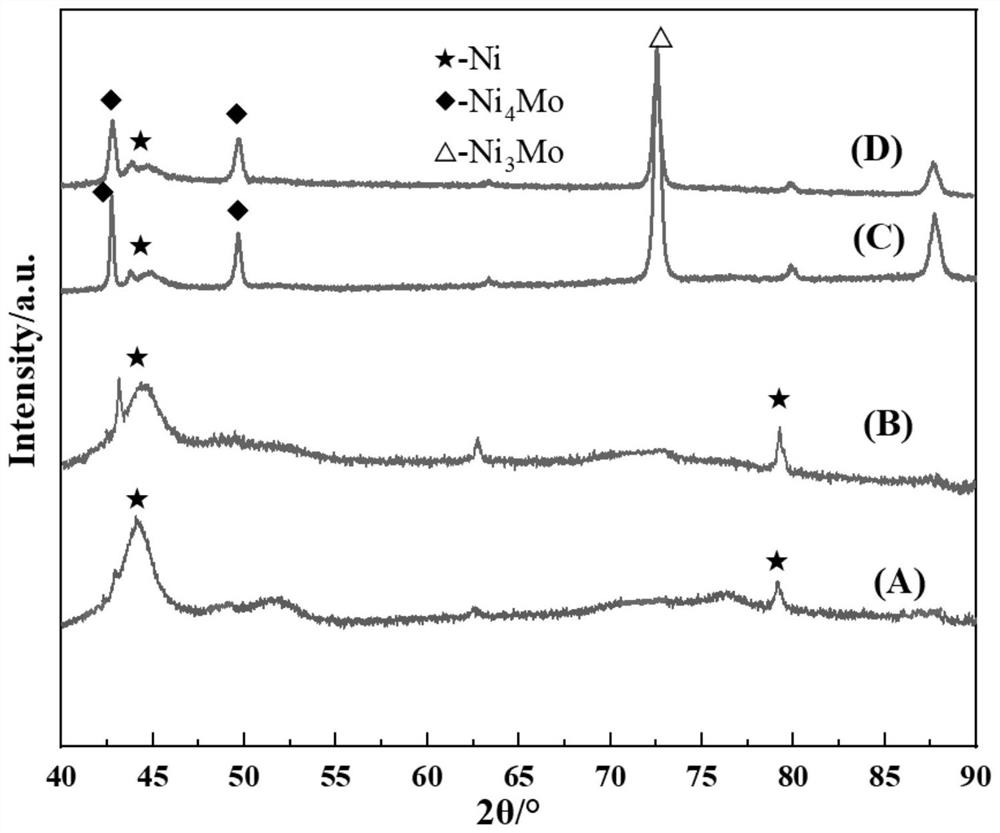

[0043] figure 2 (B) and image 3 (B) shows the phase analysis and microscopic morphology of the Ni-Mo-P nano-alloy thin film electrode obtained under the conditions of Example 3. from figure 2 (B) It can be seen that Ni begins to appear in the nanoalloy film 4 No trace of P element was found in the Mo diffraction peak, indicating that the Ni-Mo-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com