Steel for anti-corrosion steel bar for tropical ocean atmospheric environment concrete structure and production method thereof

A technology for concrete structure and ocean atmosphere, applied in the field of corrosion-resistant materials, can solve the problems of inability to use in large quantities, high content of alloy elements, rapid corrosion of galvanized layer, etc., to reduce maintenance costs in the later period, low content of alloy elements, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

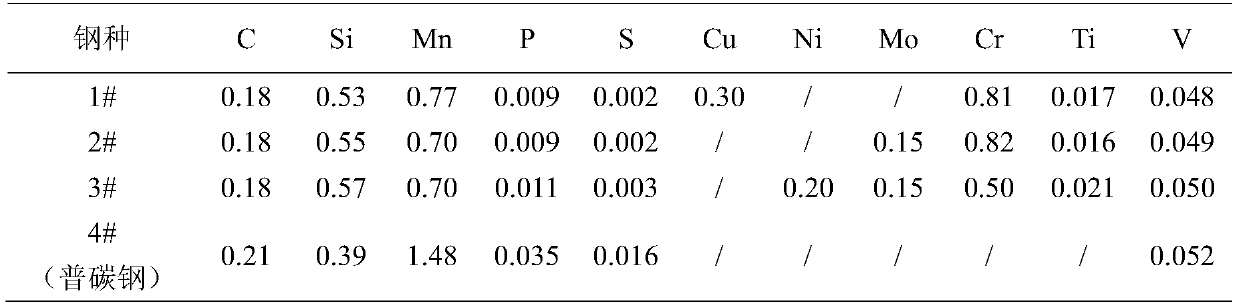

[0026] The corrosion-resistant steel bars of the present invention are based on the industry standard "Corrosion-resistant steel bars for reinforced concrete", adding a small amount of alloy elements on the basis of ordinary carbon steel components, and obtaining three new types of corrosion-resistant steel bars by optimizing the content and proportion of alloy elements.

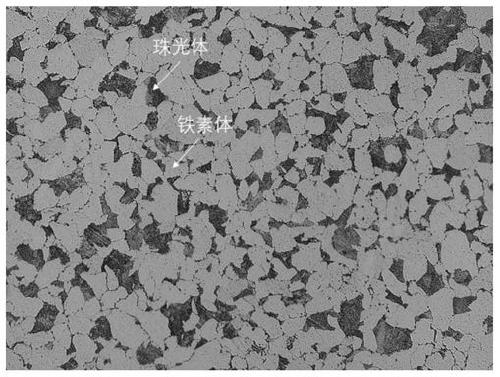

[0027] The weight percentages of the chemical components of the three newly designed corrosion-resistant steel bars and ordinary carbon steel bars are shown in Table 1. Steel bar sample metallographic structure of the present invention is as figure 1 shown.

[0028] Table 1 three types of steel chemical composition weight percentage content (wt.%)

[0029]

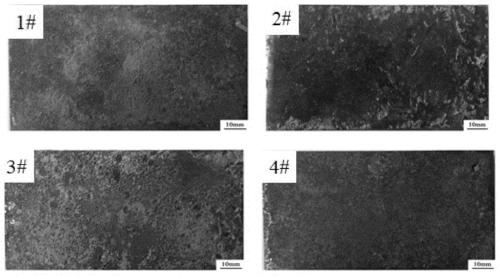

[0030] The on-site atmospheric exposure test was carried out with reference to the standard GB11112-89. The prepared reinforced concrete samples were exposed to the coastal areas of Thailand, and the exposure time was seven months. The concrete and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com