Ultrafine-grain steel pipe and process for manufacturing the same

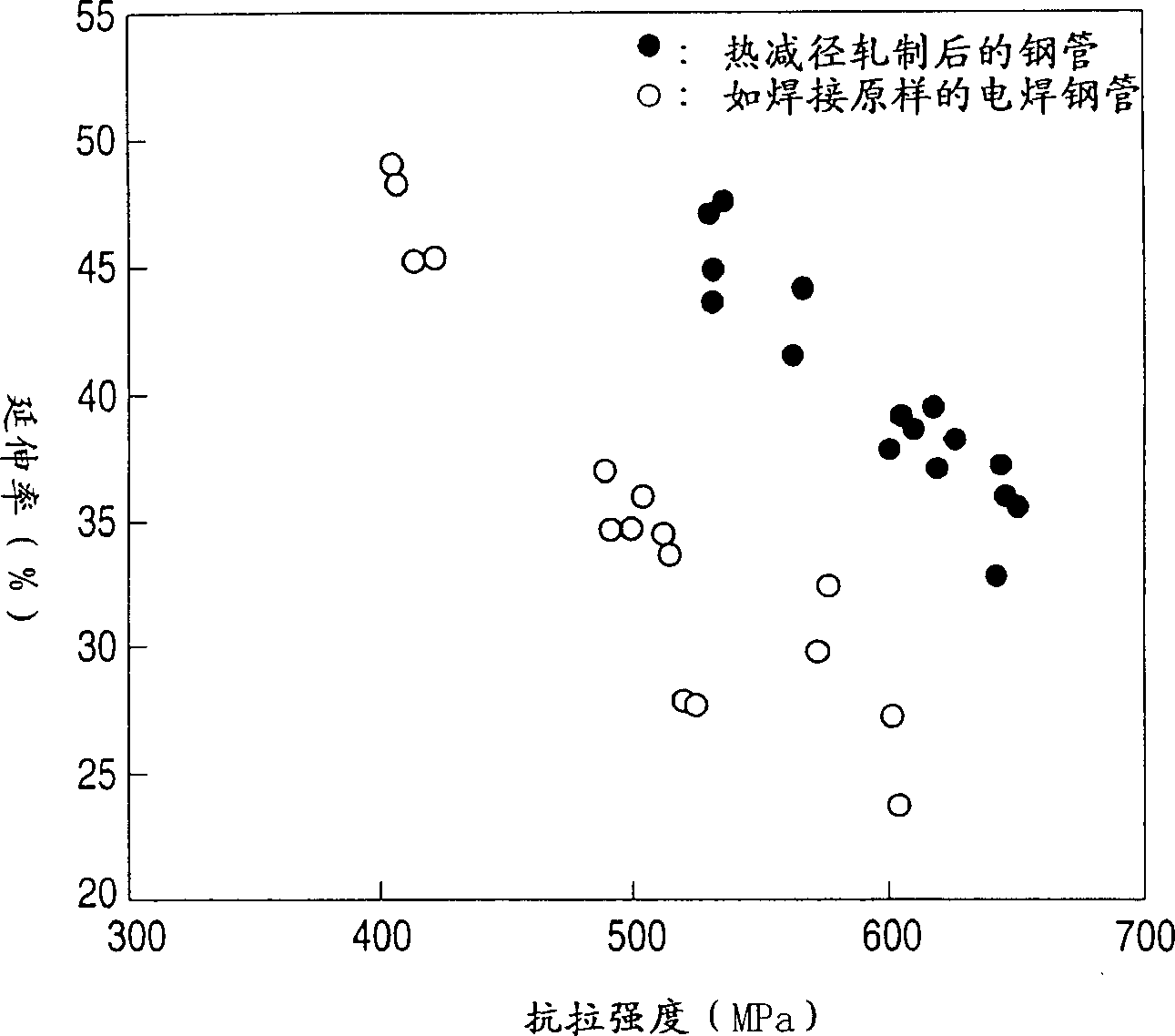

A manufacturing method and steel pipe technology, applied in metal rolling and other directions, can solve the problems of complicated process and reduced elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

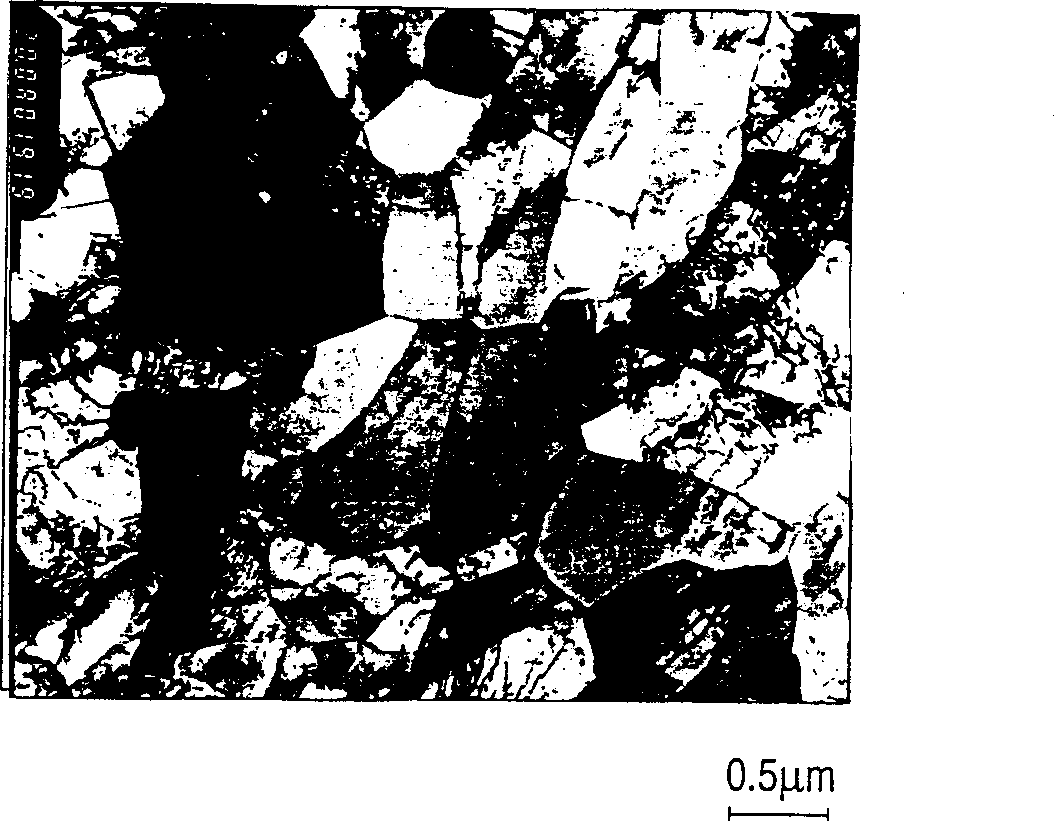

Examples

Embodiment 1

[0141] The raw steel pipes with the chemical composition shown in Table 1 were heated to the temperature shown in Table 2 with induction heating coils, and then the product tubes were made into the product tubes with the rolling conditions shown in Table 2 by a tension reducer with 3-roll structure. The solid-phase pressure-welded steel pipes shown in Table 2 used steel pipes produced by preheating a 2.6 mm thick hot-rolled strip steel to 600°C, and then forming continuously with a plurality of forming rolls to obtain open pipes, followed by , use induction heating to preheat the two edges of the open tube to 1000°C, and then use induction heating to heat the two edges to 1450°C in the unmelted temperature zone, and use extrusion rollers to butt solid phase pressure welding to form φ42.7mm× 2.6mm thick steel pipe. In addition, as the seamless steel pipe, a seamless steel pipe obtained by heating a continuous casting slab and rolling by a Mannesmann mandrel method was used.

...

Embodiment 2

[0150] The raw steel pipes with the chemical composition shown in Table 3 were heated to the temperature shown in Table 4 with induction heating coils, and then the product tubes were made by using a 3-roll tension reducer according to the rolling conditions shown in Table 4. The manufacturing method of the raw material steel pipe is the same as in Example 1.

[0151] The tensile properties, impact impact properties and structures of these product tubes were investigated in the same manner as in Example 1, and the results are shown in Table 4.

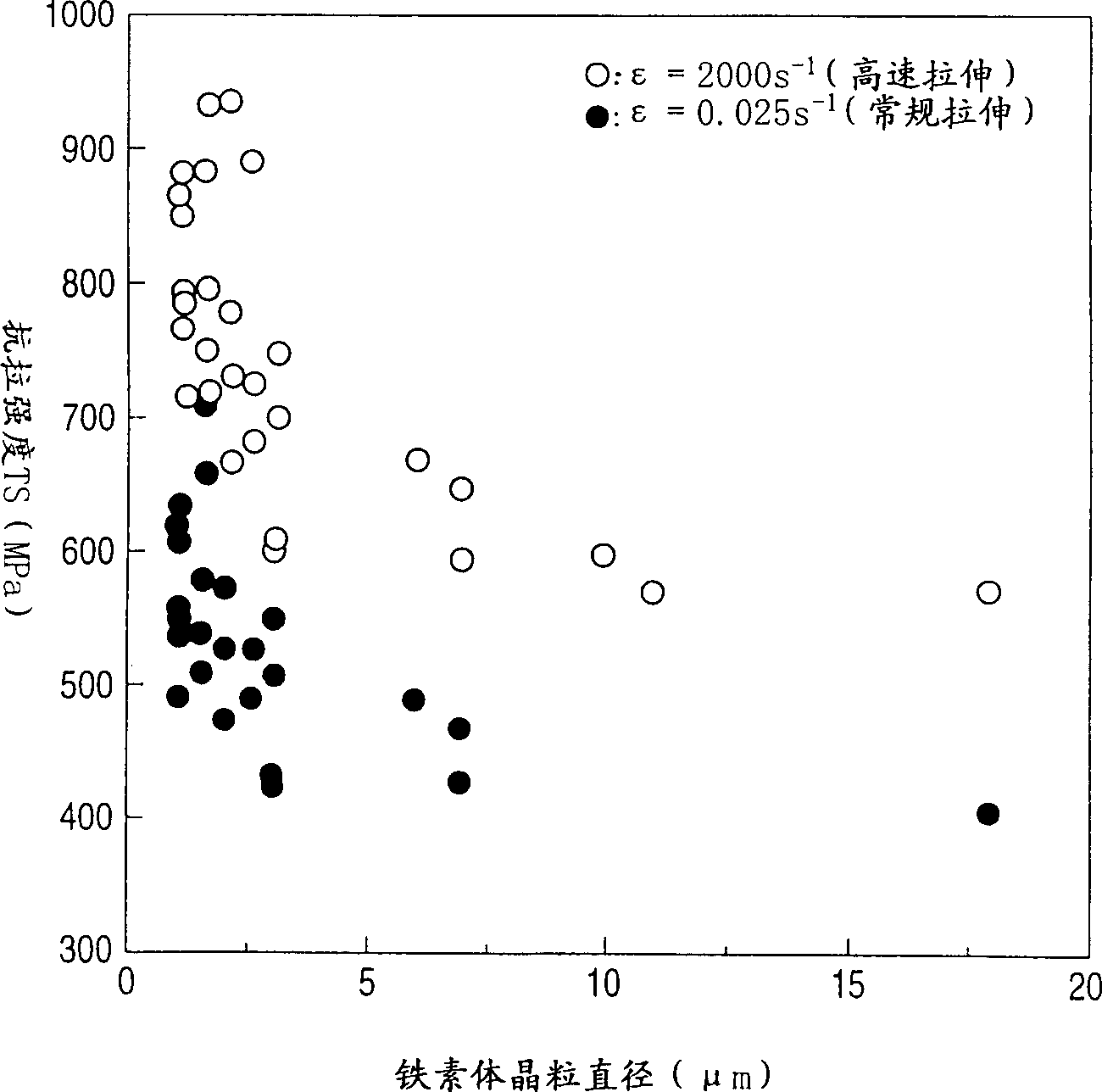

[0152] As can be seen from Table 4, the examples of the present invention (No. 2-1~No. 2-3, No. 2-6~No. 2-8, No. 2-10~No. 2-14) in the scope of the present invention obtain ductility and strength Well-balanced steel pipe. Not only the tensile strength is high at high strain rates, but also the shock absorption energy for impact resistance is high. In contrast, Comparative Examples No. 2-4, No. 2-5, and No. 2-9, which are outside the ...

Embodiment 3

[0156] Raw steel pipes with the chemical composition shown in Table 5 were heated to the temperature shown in Table 6 with induction heating coils, and then processed into product pipes by tension reduction with 3-roll structure according to the rolling conditions shown in Table 6. The steel pipe used as the raw material in this example is a φ110 mm×4.5 mm thick steel pipe made of a hot-rolled steel sheet produced by controlled rolling and controlled cooling.

[0157] The tensile properties, impact impact properties, structure and sulfide stress corrosion cracking resistance of these product pipes were investigated, and the results are shown in Table 6. Similar to Example 1, the measurement of tensile properties used JIS No. 11 test piece. In addition, considering the size effect of the test piece, the value of the elongation is calculated according to E1=E1O×((aO / a)) 0.4 (In the formula, E1O: measured elongation, aO: 292mm 2 , a: area of test piece (mm 2 )) Calculated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com