Corrosion resistant structural steel with ultra high strength

An ultra-high-strength, structural steel technology, applied in the field of alloy steel, can solve the problems of unsatisfactory use, insufficient strength, poor corrosion resistance, etc., and achieve the effect of high corrosion resistance, low raw material cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

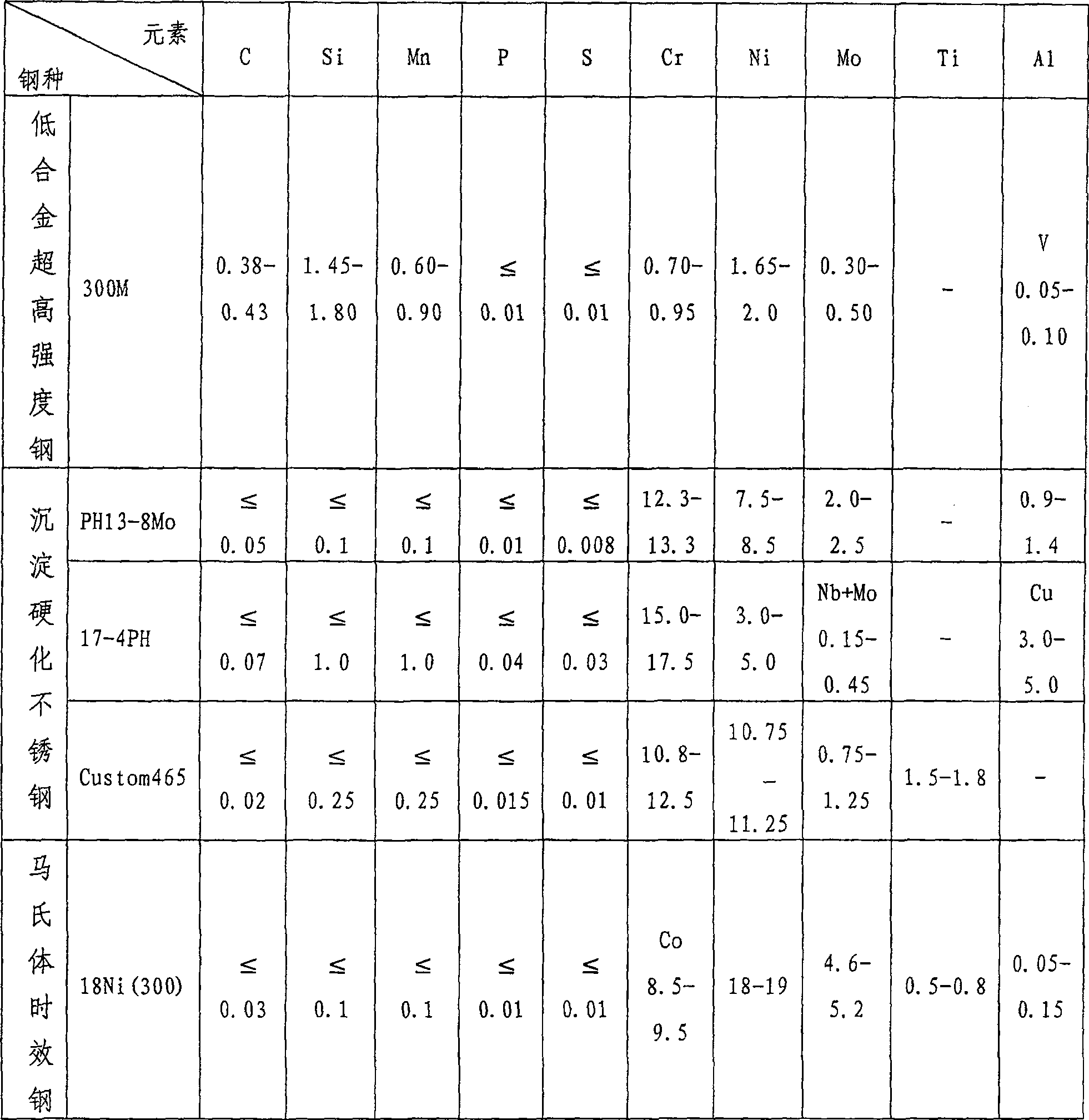

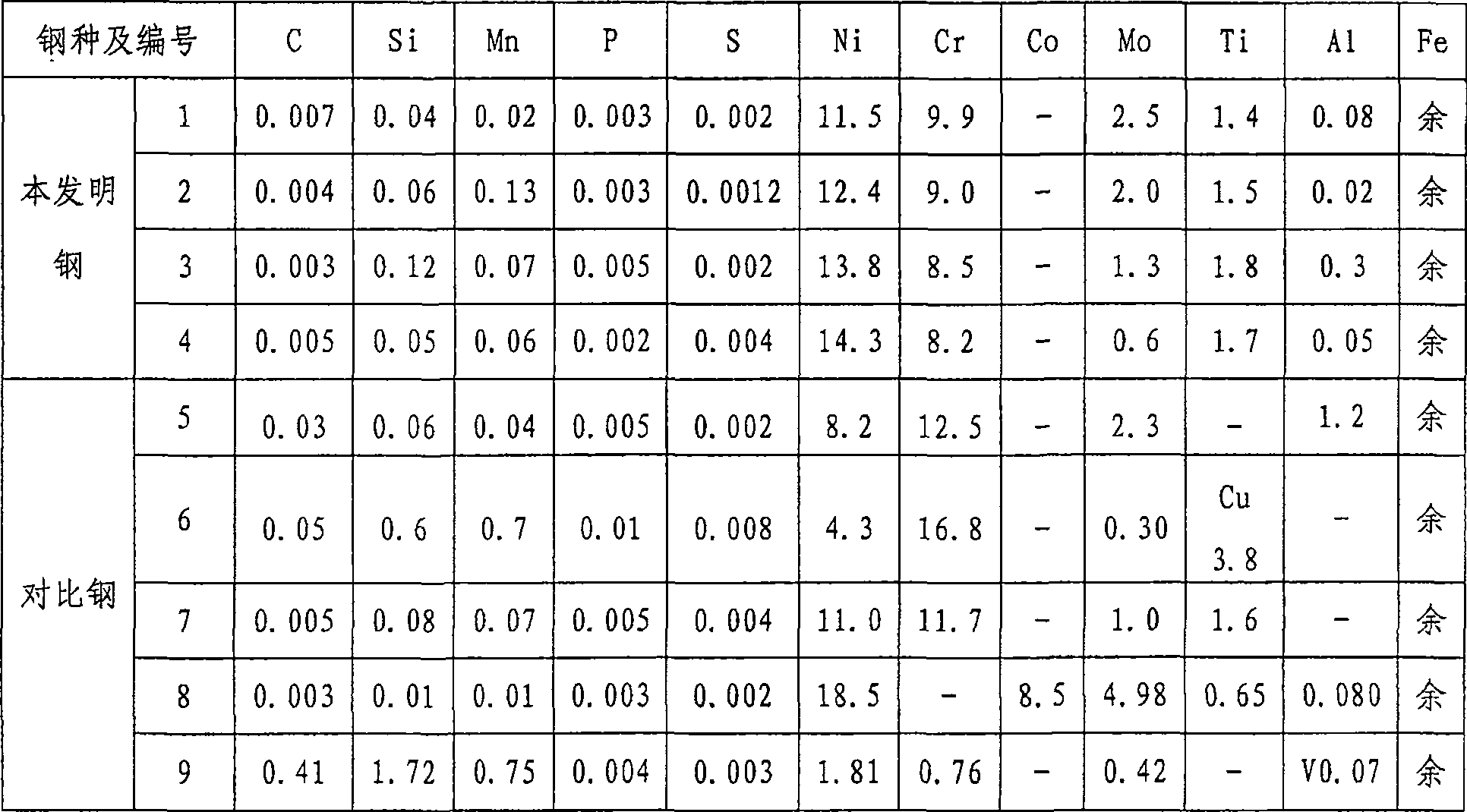

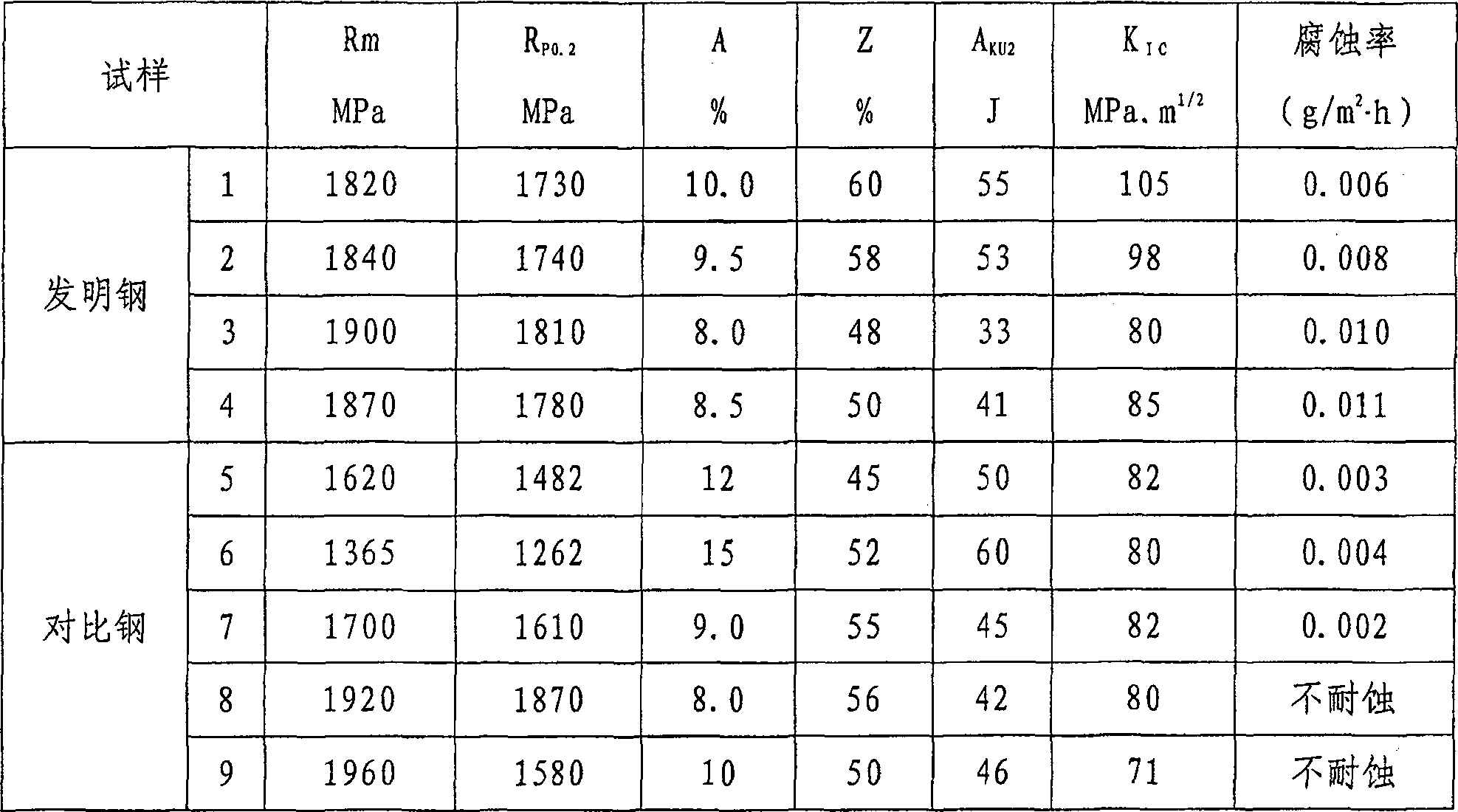

[0019] The steel of the present invention and the comparison steel were smelted by vacuum induction furnace smelting and vacuum consumable remelting, and the chemical compositions are shown in Table 2. Table 3 is a comparison table of the mechanical properties and corrosion rates of the steel of the present invention and the comparison steel. In the above list, serial number 1-4# is the embodiment of the present invention, 5# contrast steel is PH13-8Mo, 6# contrast steel is 17-4PH, 7# contrast steel is Custom465, 8# contrast steel is 18Ni maraging Steel (grade 300), 9# comparative steel is 300M. The steel ingot is forged into a steel rod with a diameter of 60mm. The steel of the present invention is subjected to solution heat treatment at 900°C×1h, and then subjected to aging treatment at 510°C×4h, while the comparison steel is subjected to normal heat treatment under appropriate conditions. Smooth tensile test, U-notch impact test and fracture toughness test were carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com