Hot rolling wire rod of 1800 MPa level for low-alloy structure and manufacture method thereof

A manufacturing method and wire rod technology, applied in temperature control and other directions, can solve the problems of adding more alloying elements, increasing material cost, and complex metallurgical process, and achieving the effects of low production cost, loose process system, and simple metallurgical process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

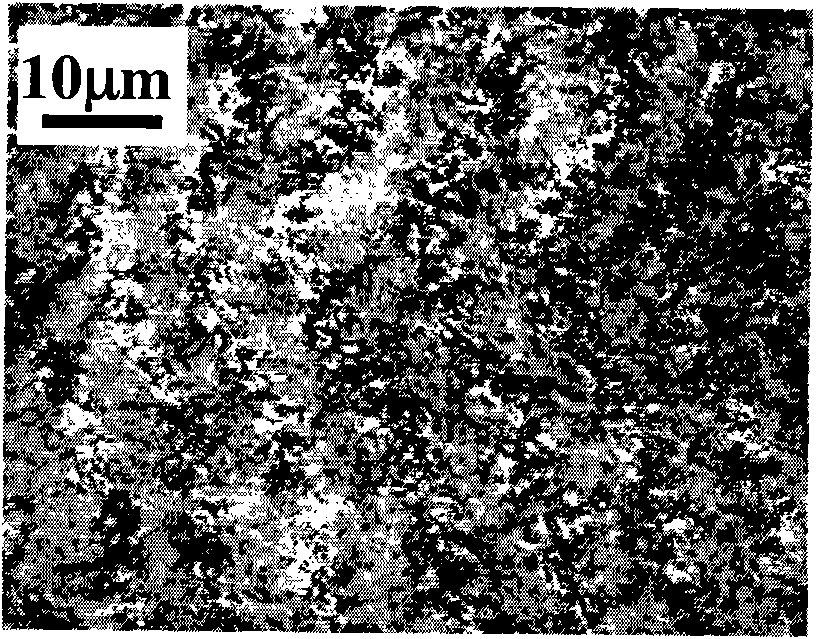

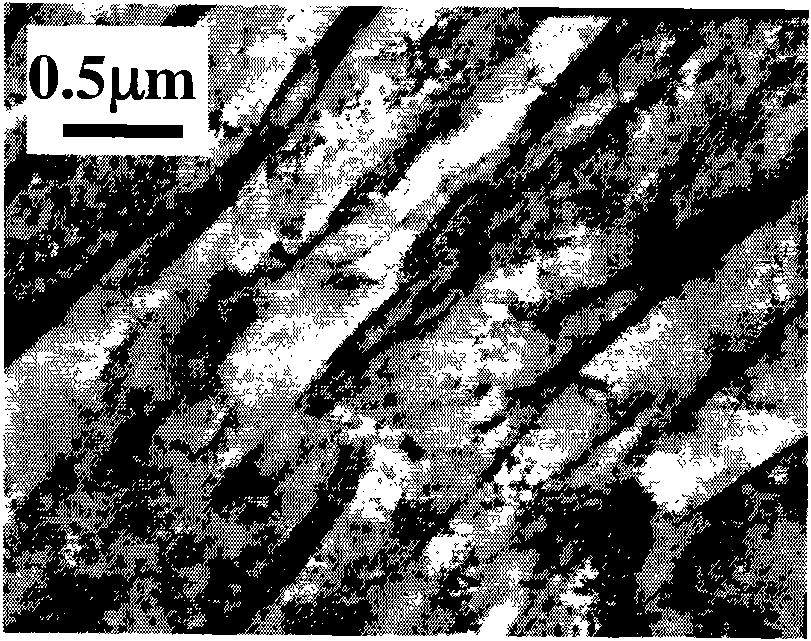

Image

Examples

Embodiment 1

[0033] Smelt molten steel in a vacuum electromagnetic induction furnace according to the chemical composition shown in Table 1, and cast it into continuous casting slabs or steel ingots, heat the continuous casting slabs or steel ingots to 1220-1270 ° C, and keep it warm for 125 minutes; then rough rolling, rough rolling The starting temperature ranges from 1140 to 1180°C, and the temperature range after rolling is from 1130 to 1160°C, rolling into bars with a diameter of φ22±0.5mm. Then finish rolling, the temperature range of finish rolling is 1000~1050℃, and the wire rod of φ9±0.3mm is rolled on the continuous rolling mill. After rolling, it is controlled and cooled by the Stelmore line, and the cooling rate is 5°C / s.

Embodiment 2

[0035] The implementation is the same as in Example 1, wherein the heating temperature is 1220-1270° C., and the temperature is kept for 130 minutes; the rough rolling start temperature range is 1140-1180° C., and the bar is rolled into a φ22±0.5mm bar. The finishing rolling heating temperature is ≥1050°C, the rolling temperature range is 1000-1050°C, and the wire rod is rolled into a wire rod of φ9±0.3mm on a continuous rolling mill. After rolling, it is controlled and cooled by the Stelmore line, and the cooling rate is 4°C / s.

Embodiment 3

[0037] The implementation is the same as in Example 1, wherein the heating temperature is 1220°C-1270°C, and the temperature is kept for 140 minutes; the rough rolling start temperature range is 1140-1180°C, and the bar is rolled into a φ22±0.5mm bar. The finishing rolling heating temperature is ≥1050°C, the rolling temperature range is 1000-1050°C, and the wire rod is rolled into a wire rod of φ9±0.3mm on a continuous rolling mill. After rolling, it is controlled and cooled by the Stelmore line, and the cooling rate is 6°C / s.

[0038] The chemical composition (wt%) of the hot-rolled wire rod of table 1 comparative example of the present invention and embodiment 1-3

[0039] C

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com