Novel low-expansion binary magnesium alloy and preparation method thereof

A magnesium alloy and low-expansion technology, which is applied in the field of new low-expansion binary magnesium alloy and its preparation, can solve the problems of high cost and brittle second equivalence, and achieve the effects of low cost, low thermal expansion coefficient and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

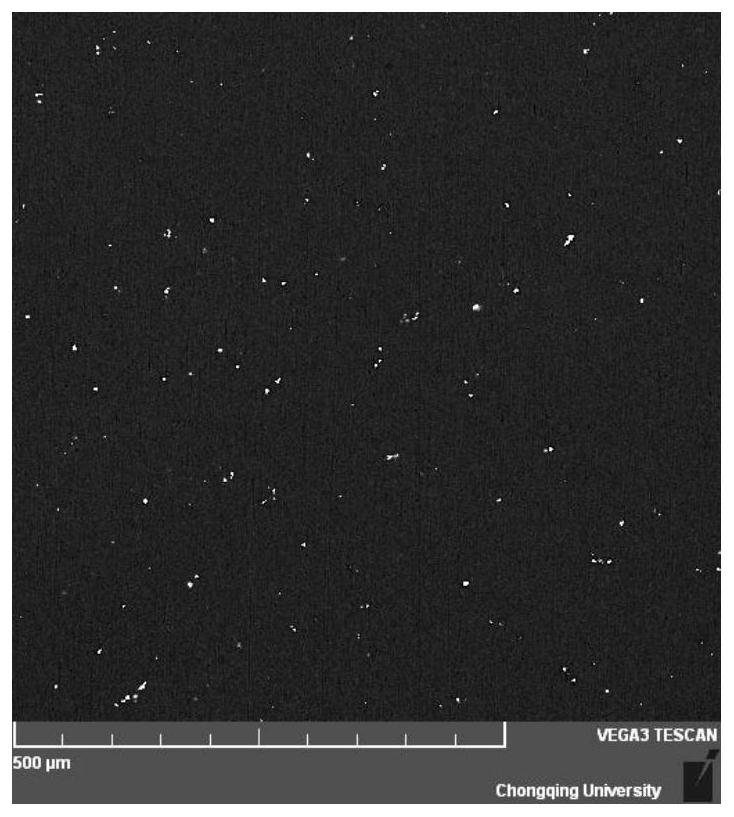

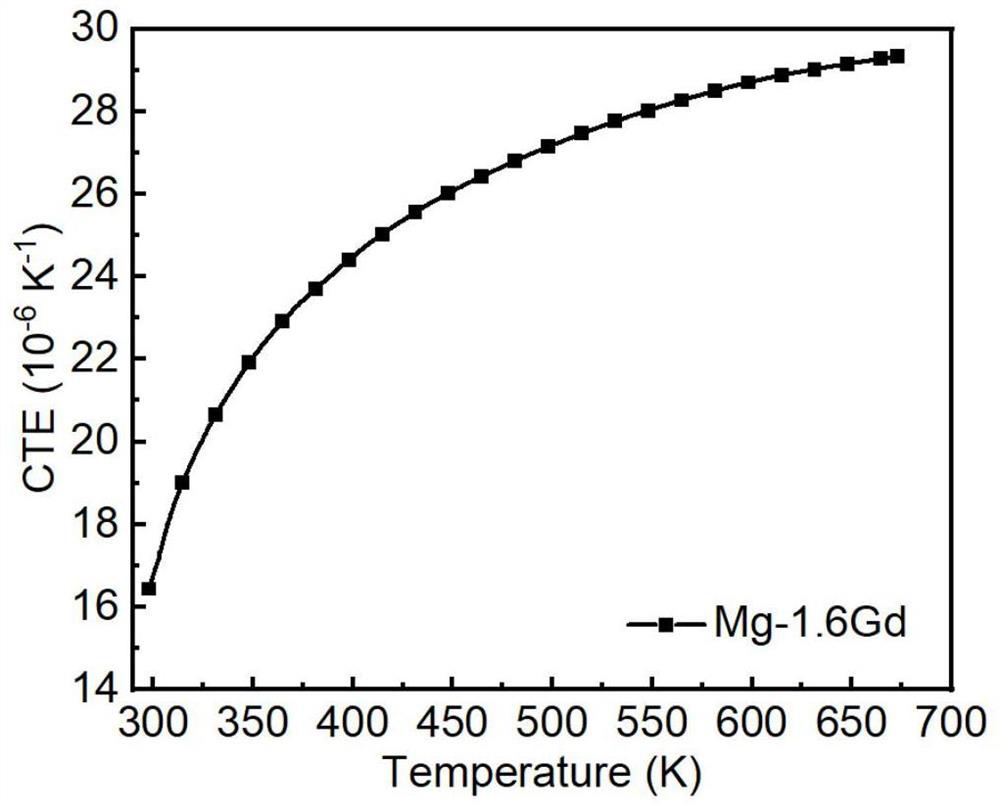

Embodiment 1

[0034] 1) A binary Mg-Gd low-expansion magnesium alloy material, wherein the content of Gd element is about 1.6wt.%, and the rest are Mg and inevitable impurity elements. Prepare materials according to the above-mentioned components and polish the raw materials to give a metallic luster. The amount is ready for use, and the raw materials used are high-purity Mg (99.99wt.%) and Mg-30wt.%Gd master alloy.

[0035]2) Put the weighed raw materials into the heat treatment furnace for preheating, the preheating temperature is 250 ℃, then put the preheated pure magnesium into the resistance furnace, the melting temperature is set to 730 ℃, in a dynamic protective atmosphere CO 2 with SF 6 Heating under mixed gas (with a ratio of 99:1), after melting, the preheated Mg-30wt.% Gd master alloy is put in, and the temperature is kept for 15-20 minutes to form an alloy melt.

[0036] 3) The magnesium alloy melt obtained in step 2) was stirred for 2 minutes, kept at 730° C. for 10 minutes, ...

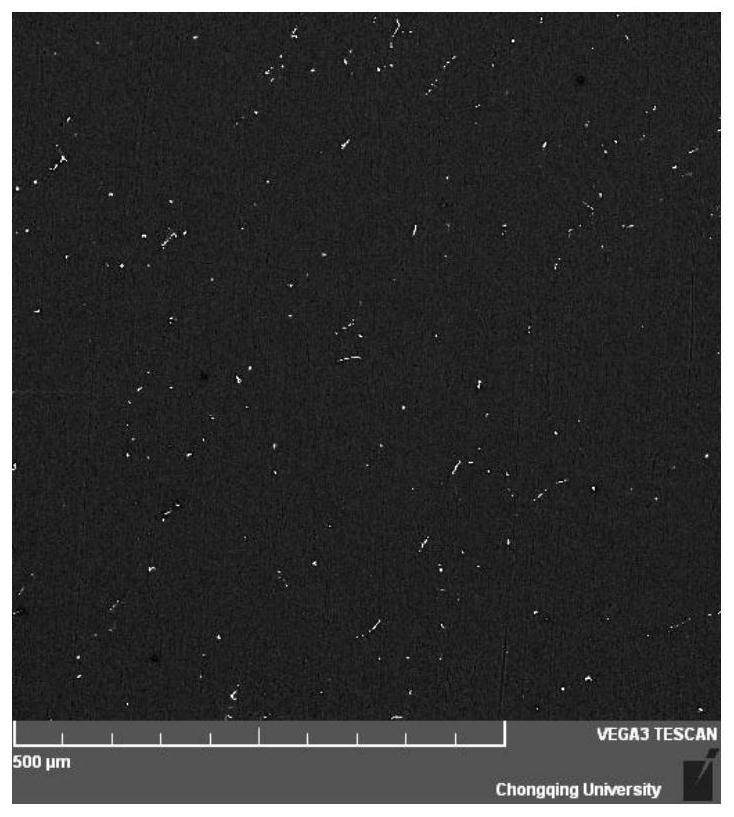

Embodiment 2

[0040] 1) A binary Mg-Gd low-expansion magnesium alloy material, wherein the content of Gd element is about 4.2wt.%, and the rest are Mg and inevitable impurity elements. Prepare materials according to the above-mentioned components and polish the raw materials to give a metallic luster. The amount is ready for use, and the raw materials used are high-purity Mg (99.99wt.%) and Mg-30wt.%Gd master alloy.

[0041] 2) Put the weighed raw materials into the heat treatment furnace for preheating, the preheating temperature is 250 ℃, then put the preheated pure magnesium into the resistance furnace, the melting temperature is set to 730 ℃, in a dynamic protective atmosphere CO 2 with SF 6 Heating under mixed gas (with a ratio of 99:1), after melting, the preheated Mg-30wt.% Gd master alloy is put in, and the temperature is kept for 15-20 minutes to form an alloy melt.

[0042] 3) The magnesium alloy melt obtained in step 2) was stirred for 2 minutes, kept at 730° C. for 10 minutes,...

Embodiment 3

[0046] 1) A binary Mg-Gd low-expansion magnesium alloy material, wherein the content of Gd element is about 10.6wt.%, and the rest are Mg and inevitable impurity elements. Prepare materials according to the above-mentioned components and polish the raw materials to give a metallic luster. The amount is ready for use, and the raw materials used are high-purity Mg (99.99wt.%) and Mg-30wt.%Gd master alloy.

[0047] 2) Put the weighed raw materials into the heat treatment furnace for preheating, the preheating temperature is 250 ℃, then put the preheated pure magnesium into the resistance furnace, the melting temperature is set to 730 ℃, in a dynamic protective atmosphere CO 2 with SF 6 Heating under mixed gas (with a ratio of 99:1), after melting, the preheated Mg-30wt.% Gd master alloy is put in, and the temperature is kept for 15-20 minutes to form an alloy melt.

[0048] 3) The magnesium alloy melt obtained in step 2) was stirred for 2 minutes, kept at 730° C. for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com